High-sensitivity optical fiber temperature sensing probe and manufacturing method thereof

An optical fiber temperature, sensing probe technology, applied in thermometers, thermometers with physical/chemical changes, measurement devices, etc., can solve the problem of reducing the cost and difficulty of demodulation, the small detection range of fiber optic temperature probes, and increasing the cost and difficulty of demodulation and other problems, to achieve the effect of ensuring the detection sensitivity and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

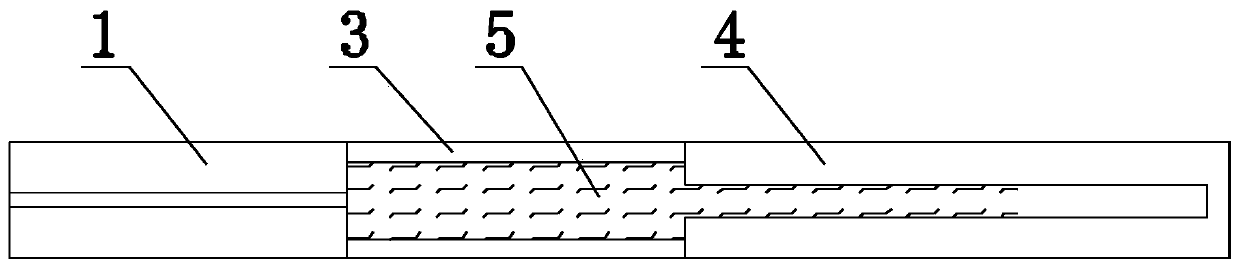

[0022] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a high-sensitivity optical fiber temperature sensing probe proposed by the present invention.

[0023] refer to figure 1 , a high-sensitivity optical fiber temperature sensing probe proposed by the present invention, comprising: a probe body;

[0024] A sealed space is provided in the probe body, and the side wall of the sealed space is provided with an entrance and exit window, and the sealed space includes a first lumen and a second lumen that are sequentially connected in a direction away from the entrance and exit window. The lumen is filled with volatile liquid 5 .

[0025] In the specific working process of the high-sensitivity optical fiber temperature sensing probe of this embodiment, a laser and an optical power meter are connected to the incident window of the probe body, and the probe body is placed vertically so that the incident window is located at the bottom of the sealed space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com