Preparation method and application of Pt/SAPO-11 dual-functional catalyst

A SAPO-11, dual-functional catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of weak interaction between metal active centers and molecular sieves, and achieve enhanced interaction and hydrogenation The effect of isomerization yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Di-n-propylamine is selected as the microporous template agent. Before the reaction, di-n-propylamine and phosphoric acid, the reaction raw material, are used to form di-n-propylamine phosphate. The reaction molar ratio of di-n-propylamine and phosphoric acid is 1:1.0-1:1.2.

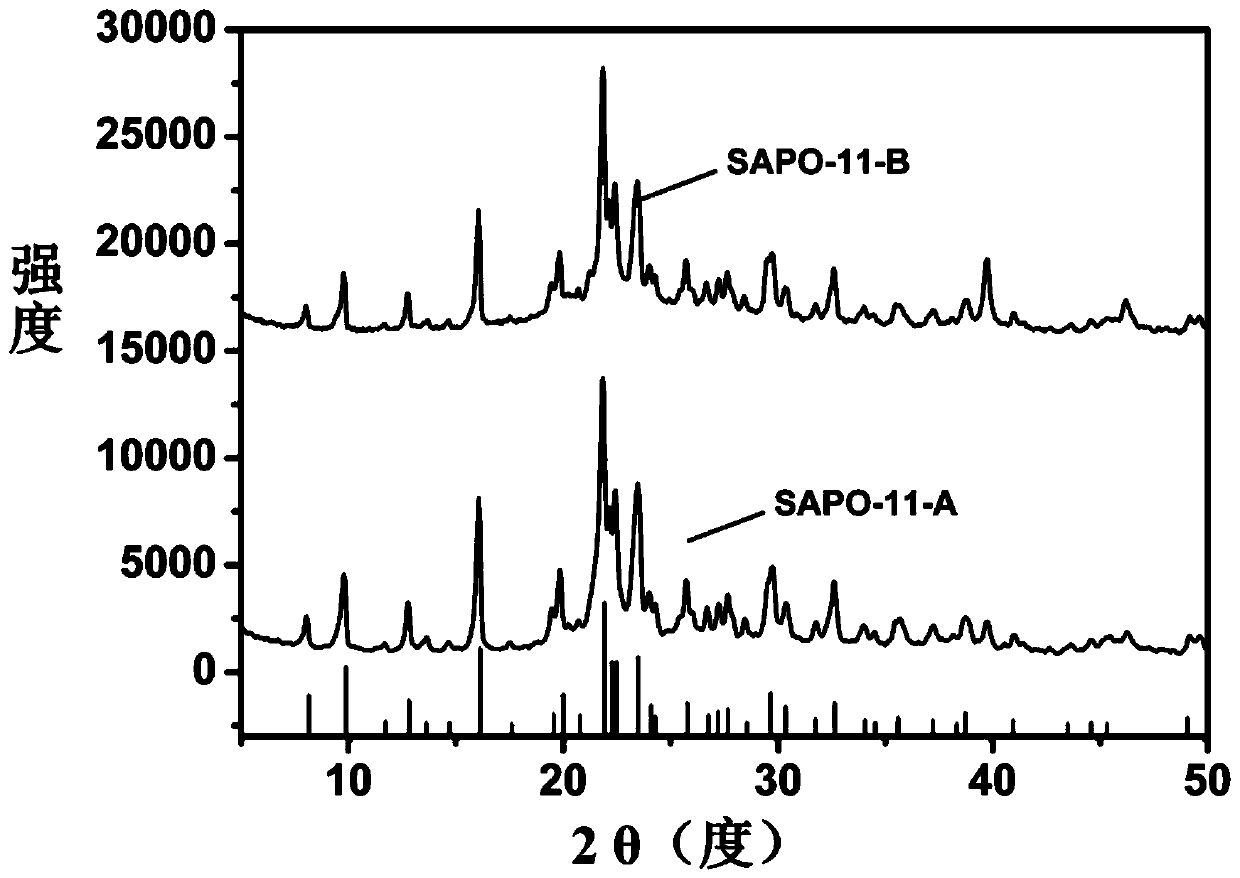

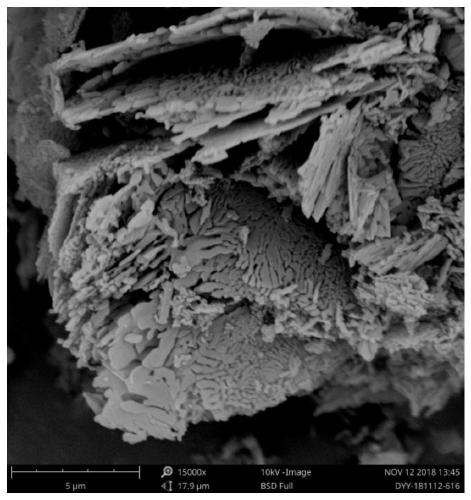

[0030] 1.05 mL of H with a concentration of 0.245 mol / L 2 PtCl 6 The solution was impregnated onto 0.25g of white carbon black, impregnated at room temperature for 24h, dried, and sintered to obtain Pt / SiO 2 . Pt / SiO 2 After mixing with 2.912g of pseudo-boehmite and 6.28g of di-n-propylamine phosphate, grind for 10 minutes, put the obtained powder into the reaction kettle, crystallize at 200°C for 24 hours, and centrifuge the obtained product Washing, drying at 80°C and roasting at 600°C for 6h to obtain the final product. The resulting product was named SAPO-11-B. The loading of Pt in the obtained Pt / SAPO-11-B was about 0.7%.

Embodiment 2

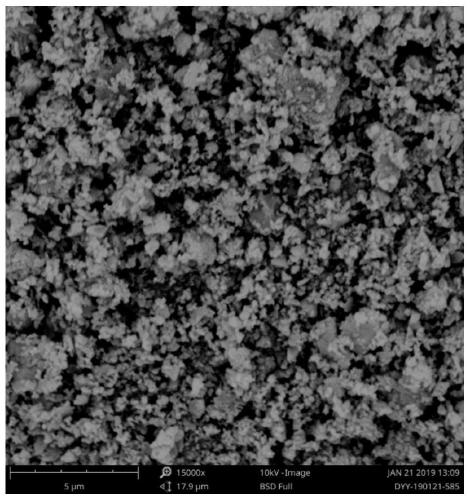

[0040] 1.05 mL of Pt(NO with a concentration of 0.265 mol / L 3 ) 2 The solution was impregnated onto 0.25g of white carbon black, impregnated at room temperature for 24h, dried, and sintered to obtain Pt / SiO 2 . Pt / SiO 2 After mixing with 2.912g of pseudo-boehmite and 6.28g of di-n-propylamine phosphate, grind for 10 minutes, put the obtained powder into a reaction kettle, crystallize at 200°C for 24 hours, and centrifugally wash the obtained product , dried at 80°C and calcined at 600°C for 6h to obtain the final product.

Embodiment 3

[0042] 1.05 mL of Pt(NH 3 ) 4 Cl 2 The solution was impregnated onto 0.25g of white carbon black, impregnated at room temperature for 24h, dried, and sintered to obtain Pt / SiO 2 . Pt / SiO 2 After mixing with 2.912g of pseudo-boehmite and 6.28g of di-n-propylamine phosphate, grind for 10 minutes, put the obtained powder into a reaction kettle, crystallize at 200°C for 24 hours, and centrifugally wash the obtained product , dried at 80°C and calcined at 600°C for 6h to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com