An O-ring ring mechanism

A snare and ferrule technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of incompatibility of O-rings, insufficient design of ferrules, poor compatibility and universality, etc., and reduce equipment cost investment , Improve the working efficiency of the ferrule and reduce the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

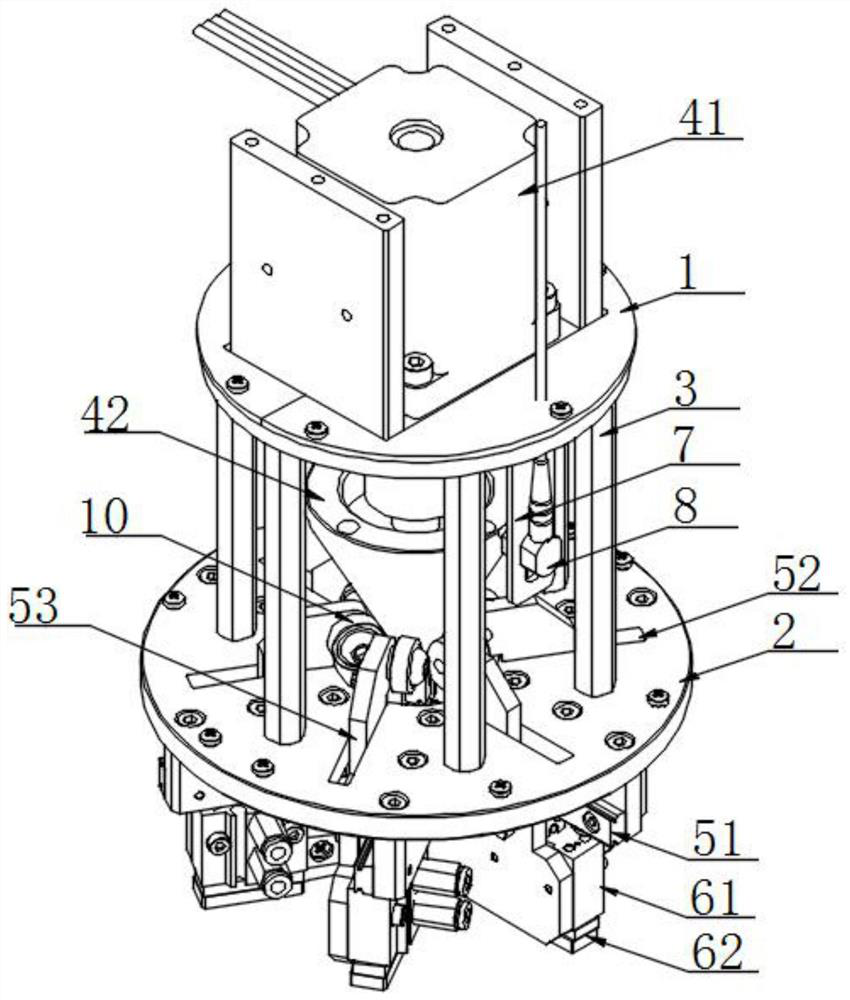

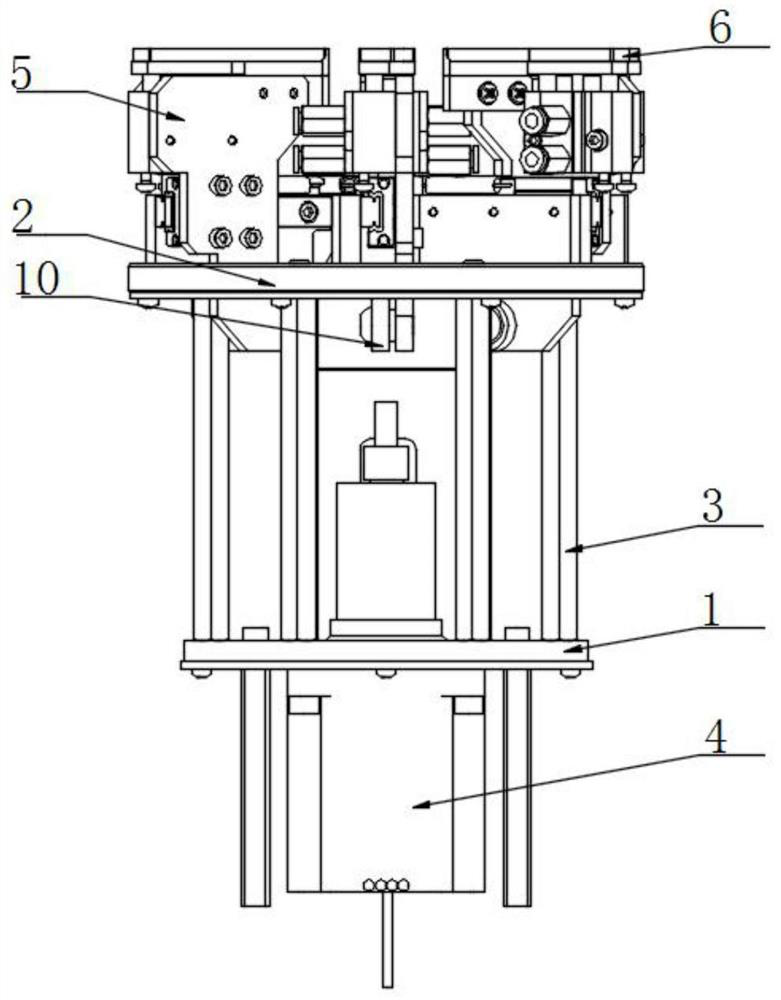

[0044] The embodiment is specifically: the origin sensor 8 senses the photoelectric signal of the position of the strut vertebral body 42, and converts the photoelectric signal into an electrical signal and sends it to the single-chip microcomputer 9 for analysis and processing. The stepping motor 41 stops working, and at this moment, the support ring plate 53 and the support ring claw 54 reset and close together under the active force of the back-moving spring 55, and the device returns to the original state, which helps to reduce energy waste. The reciprocating movement of the position is beneficial to realize the automatic ferrule work, reduce the labor intensity of the manual ferrule, and improve the efficiency.

[0045] The working principle of the present invention:

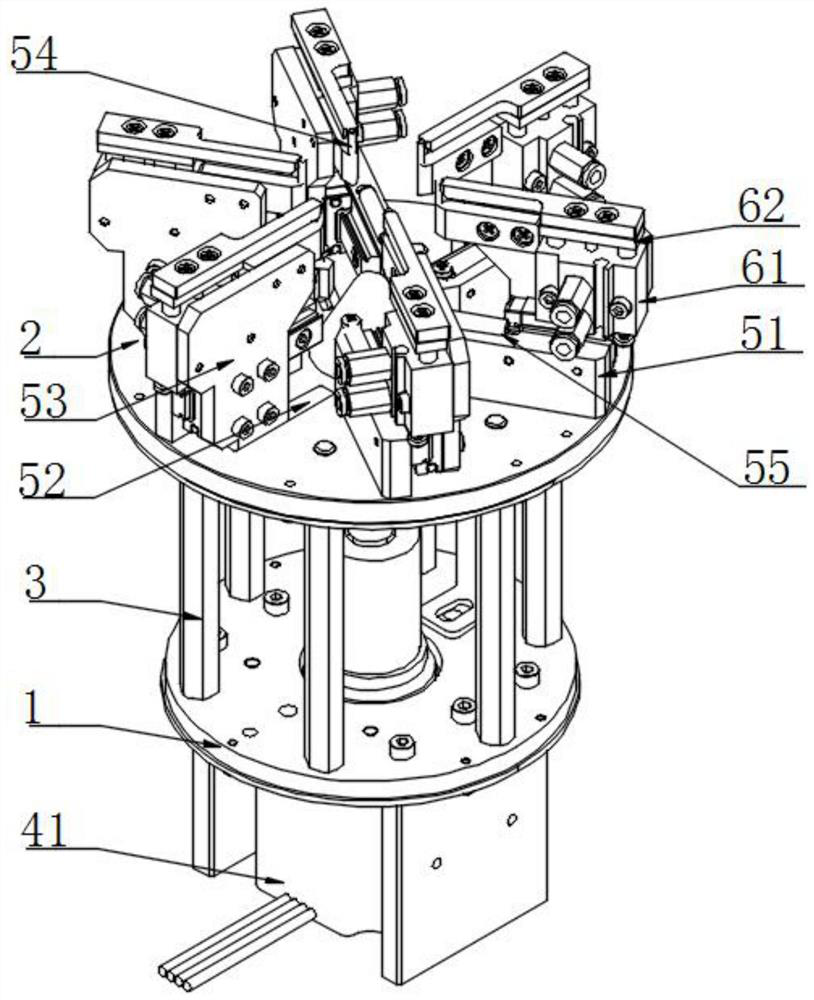

[0046] Refer to the attached Figure 1-6 , set the O-rings on the closed multiple support ring claws 54, start the linear stepping motor 41, the output shaft of the linear stepping motor 41 rotates to lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com