Safety automatic control system of railway endless rope traction shuttle car

An automatic control system and safety control technology, applied in railway vehicles, motor vehicles, cable railways, etc., can solve problems such as inability to judge the working state of shuttle cars, high maintenance and replacement costs, false alarms and damage, and save labor costs. , saving maintenance and replacement costs, and the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

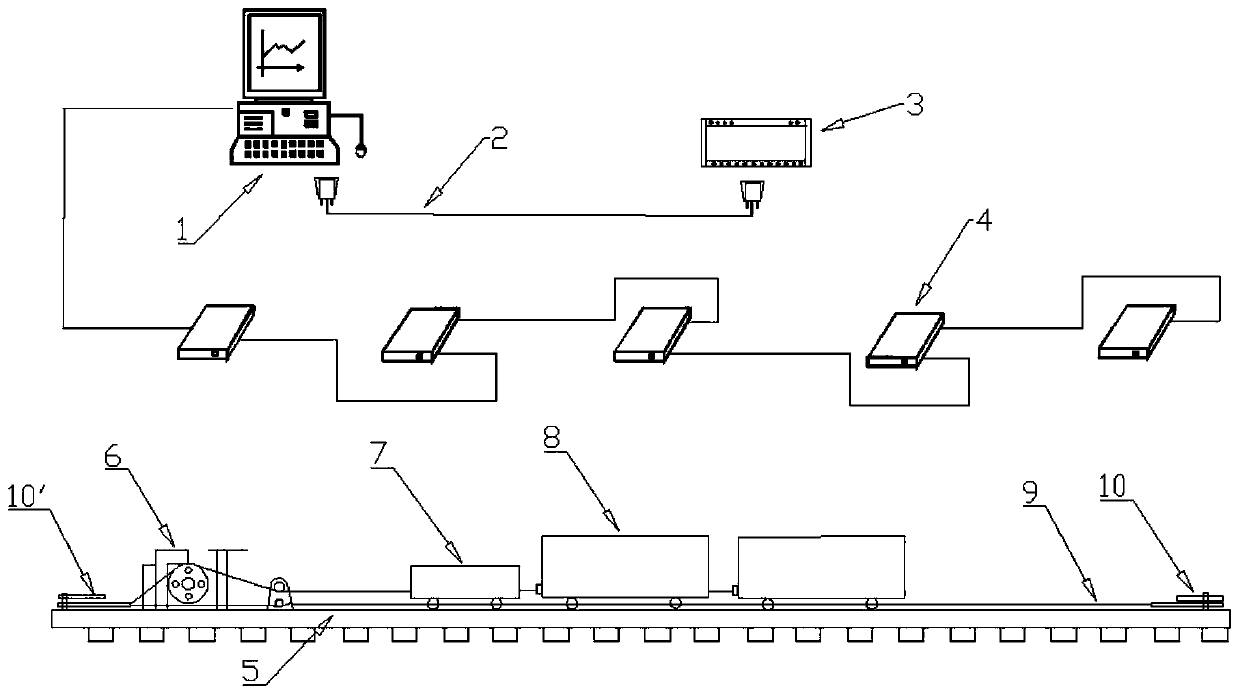

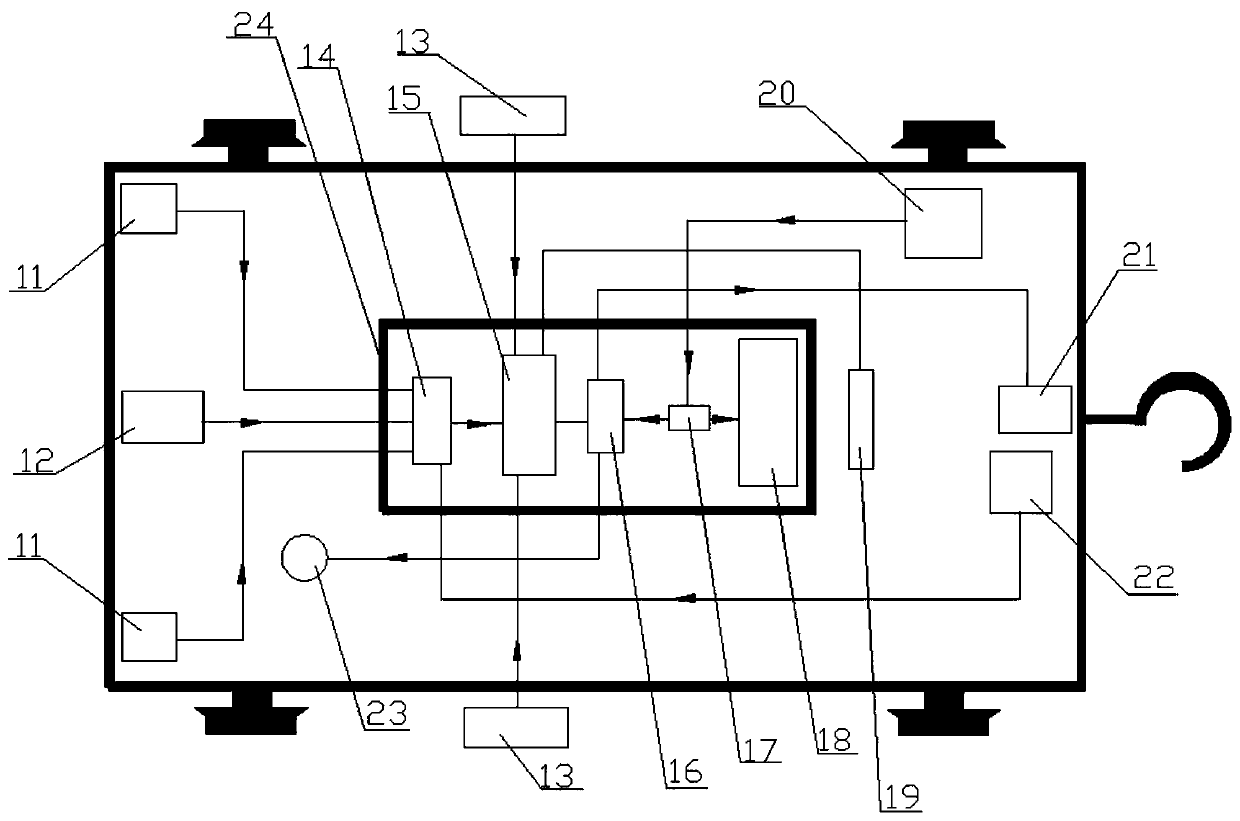

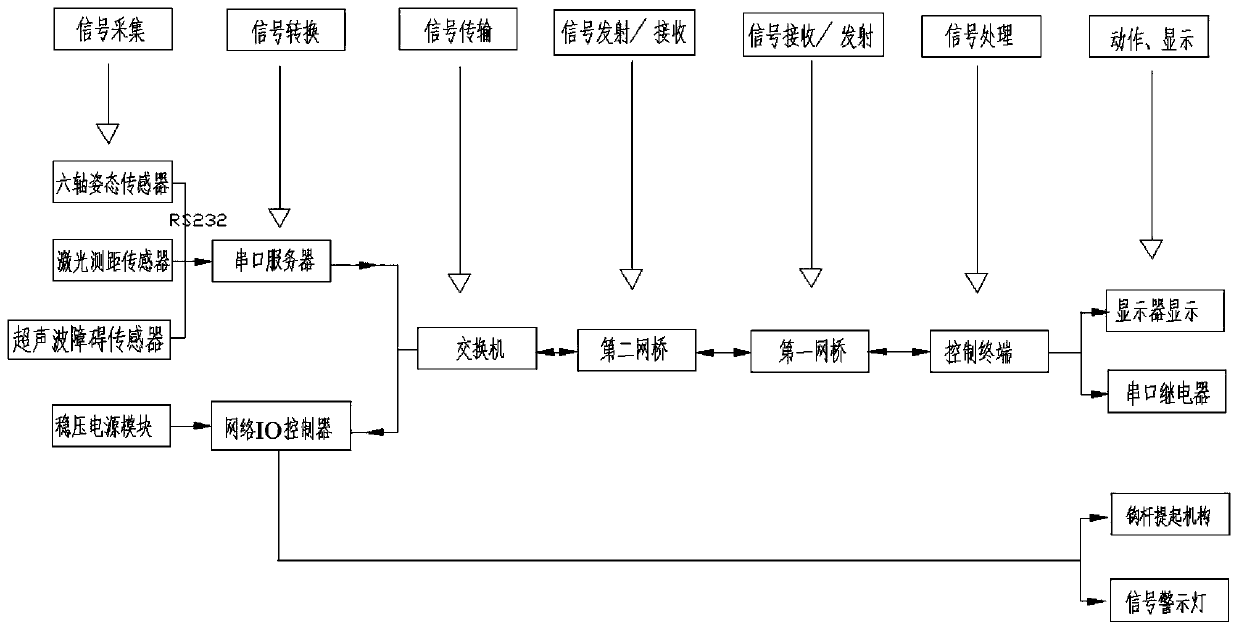

[0025] Such as figure 1 with image 3As shown, the railway endless rope traction shuttle car safety automatic control system in the present embodiment includes a railway endless rope loading system and a shuttle car safety control system, and the railway endless rope loading system includes a track 5 and an endless rope winch 6 , a shuttle car 7, several compartments 8, a first wire rope 9, a first tail wheel 10 and a second tail wheel 10', the shuttle car safety control system includes a control terminal 1, a serial port line 2, a serial port relay 3, several First network bridge 4, two six-axis attitude sensors 11, ultrasonic obstacle sensor 12, serial port server 14, switch 15, network IO controller 16, regulated power supply module 17, battery 18, second network bridge 19, sliding charging Device 20, hook lever lifting mechanism 21, laser distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com