A heat-resistant and wear-resistant nano-hybrid epoxy coating

A kind of epoxy coating, nano technology, applied in epoxy coating, coating and other directions, can solve the problems of insufficient stiffness, poor wear resistance, low temperature resistance level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

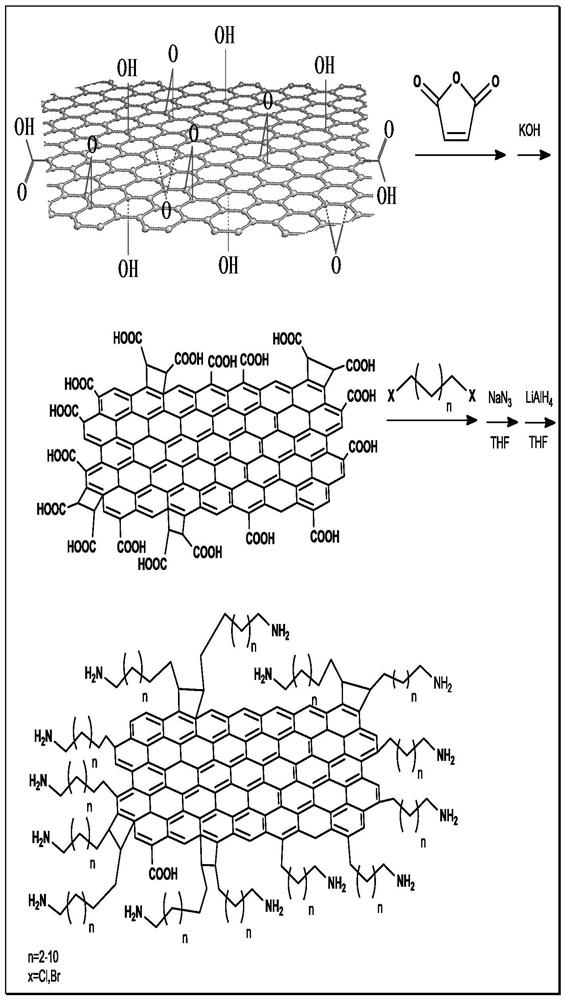

[0067] First, the graphite or graphene material is oxidized by the Hummers method to obtain graphene oxide. 0.2 g of graphene oxide was ultrasonically dispersed in 100 ml of tetrahydrofuran solution for 15 minutes, and a graphene oxide colloidal solution was obtained after ultrasonic dispersion.

[0068] Then add 0.4 g of maleic anhydride to the graphene oxide colloidal solution, and ultrasonically disperse for 15 minutes. The graphene oxide / maleic anhydride / THF mixture was irradiated in a Co-60 source with a radiation dose of 40 kGy and a dose rate of 25 Gy / min. The modified graphene oxide is obtained after the insoluble matter in the mixed solution after irradiation is suction-filtered, washed to neutrality and dried.

[0069] Weigh 0.2 g of modified graphene oxide, soak in 1 mmol / L KOH aqueous solution and 1 mmol / L hydrochloric acid solution for 5 minutes and 10 minutes respectively for hydrolysis. After the product was suction-filtered and washed with deionized water to ...

Embodiment 2

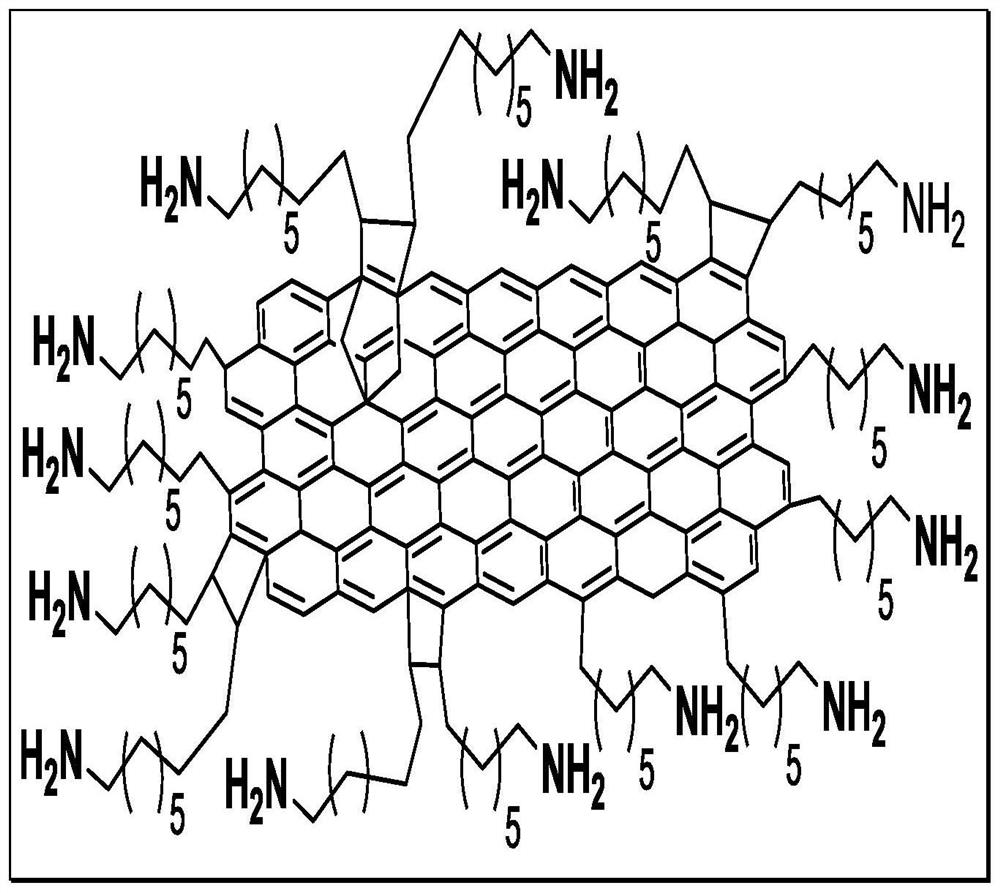

[0076] Get the graphene material (structure such as figure 2 shown), the surface density of amino groups was measured to be 12.6nmol / cm 2 , added to 100ml of toluene and stirred evenly, then added 100g of epoxy resin E51 and stirred evenly to obtain a heat-resistant and wear-resistant nano-hybrid epoxy coating, and then sprayed on the surface of a steel sheet to prepare a test sample, dried and cured at room temperature for 24 hours. After testing, the thermal decomposition temperature of the cured coating reaches 335° C., and the wear rate during sand erosion is 1.6 μm / a (sand content 2%, water velocity 5 m / s).

Embodiment 3

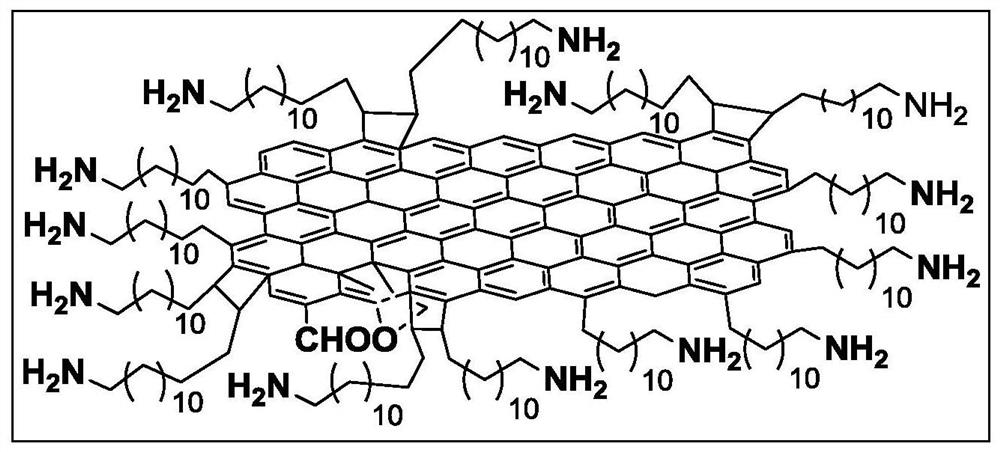

[0078] Get the graphene material (structure such as image 3 shown), the surface density of amino groups was calculated to be 10.8nmol / cm 2 , added to 70ml of toluene and stirred evenly, added 50g of epoxy resin AG80 and stirred evenly to obtain a heat-resistant and wear-resistant nano-hybrid epoxy coating, and then sprayed on the surface of the steel sheet to prepare a test sample, dried and cured at room temperature for 24 hours. After testing, the thermal decomposition temperature of the cured coating reaches 363° C., and the wear rate during sand erosion is 1.3 μm / a (sand content 2%, water velocity 5 m / s).

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com