Gas emptying silencer

A muffler and gas technology, applied in the field of gas venting mufflers, can solve serious accidents and other problems, and achieve the effects of increasing the contact area, reducing the air velocity, and reducing the injection noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

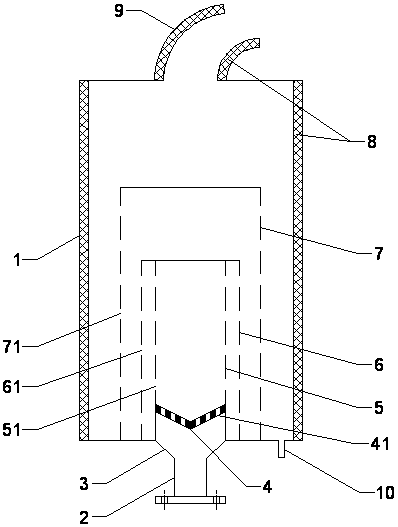

[0017] Such as figure 1 As shown, a gas venting muffler is composed of a straight inlet pipe 2, a conical expanding pipe 3, a cylinder body 1, a tapered orifice plate 4, a first-stage throttling and pressure-reducing pipe 5, and a second-stage throttling and pressure-reducing pipe 6 , small hole injection pipe 7, resistive sound-absorbing material 8, exhaust elbow 9, drain pipe 10 composition. The inside of the cylinder 1 is sequentially provided with a tapered orifice plate 4, a first-stage throttle and pressure-reducing pipe 5, a second-stage throttle and pressure-reducing pipe 6, and a small hole injection pipe 7. The opening at the bottom of the cylinder 1 is connected with an air intake section. The air intake section is composed of a conical expander pipe 3 and a straight air intake pipe 2. The top opening of the cylinder body 1 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com