Water and steam flow calculation method based on measurement of throttling device

A technology of throttling device and steam flow, which is applied in the direction of measuring fluid flow, calculation, and volume/mass flow generated by mechanical effects through measuring pressure difference, and can solve the problems of poor accuracy, inability to compensate, and unavailability of medium flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

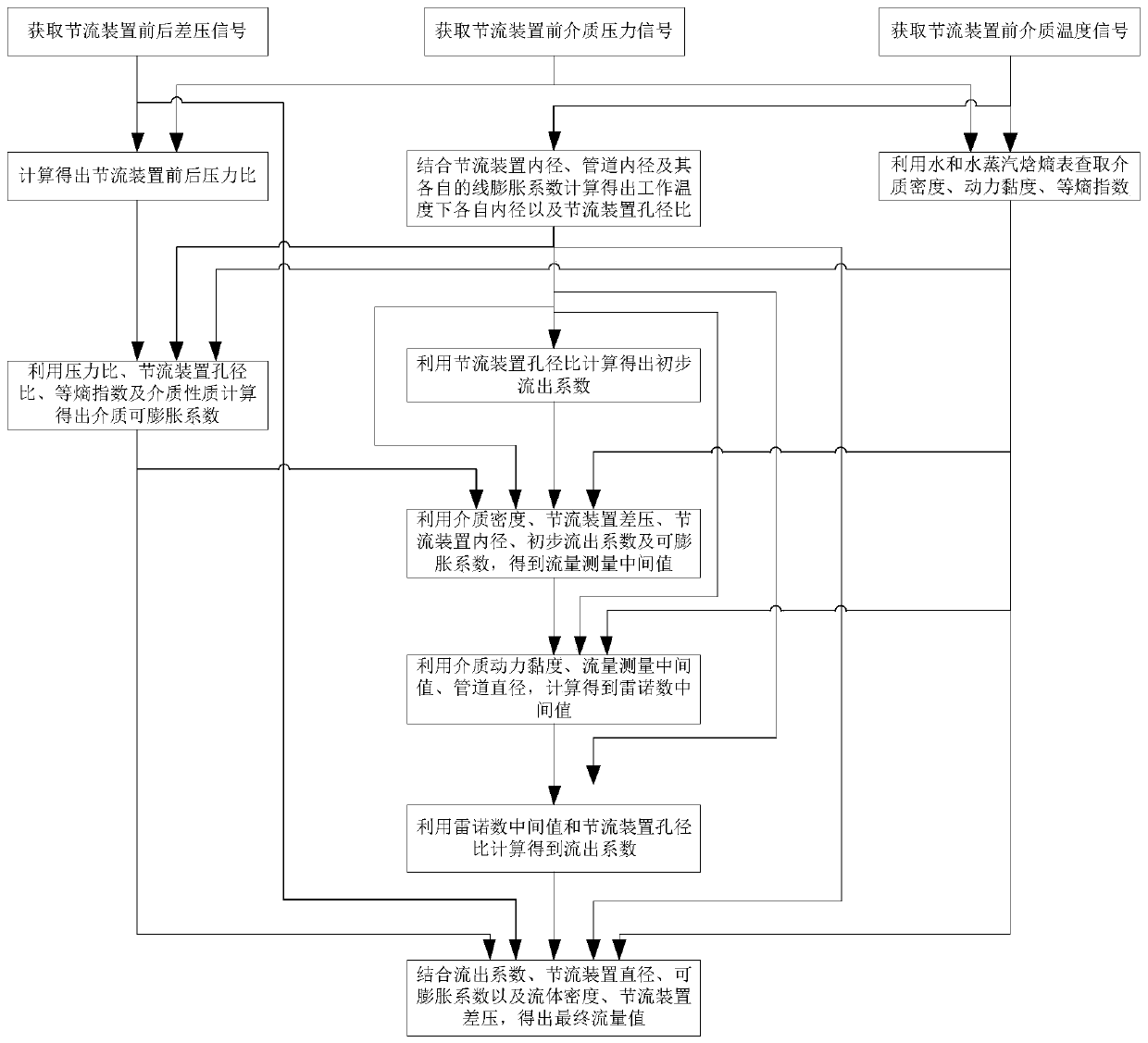

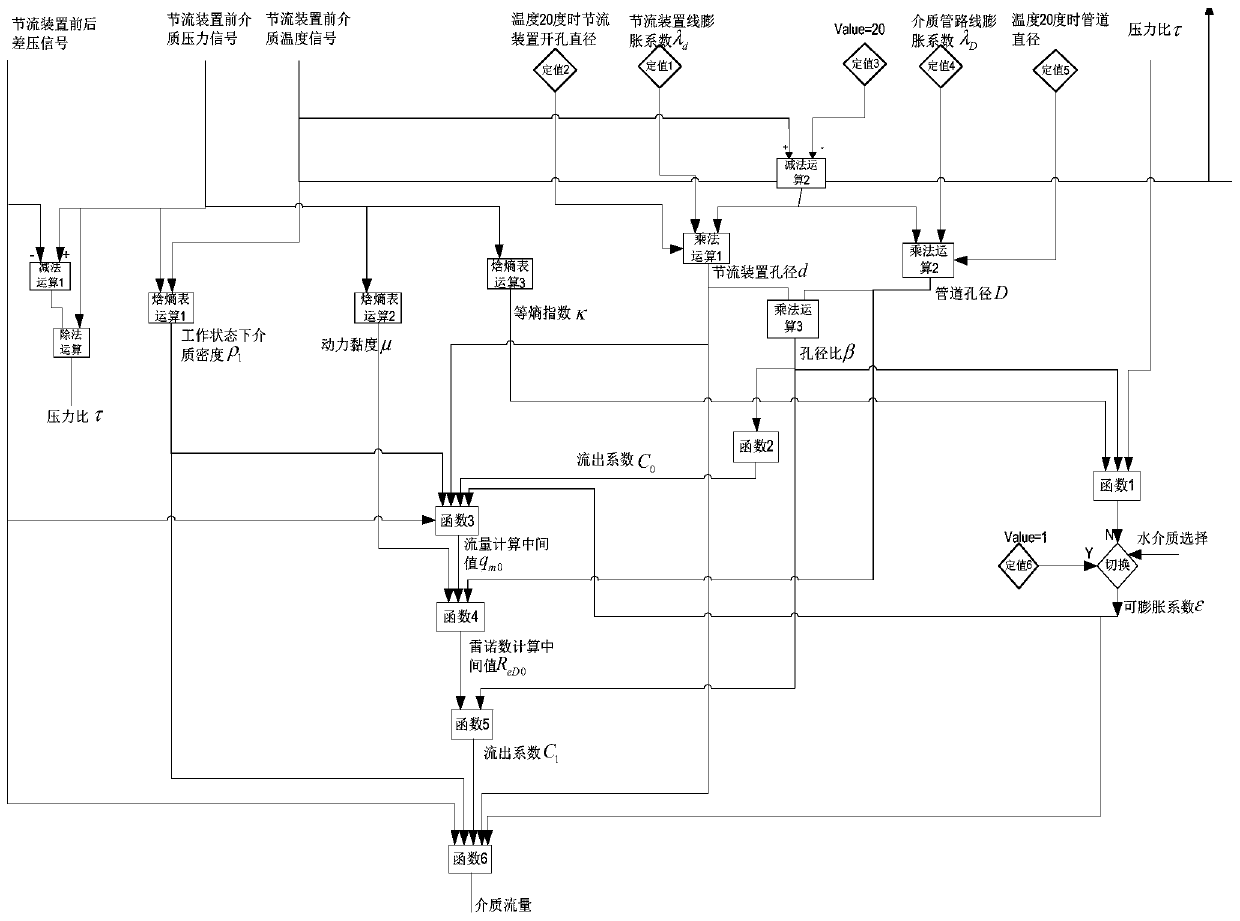

[0150] combined with figure 1 , because the standard throttling device proposed in the present invention mainly includes three types of throttling devices: standard orifice plate, ISA1932 nozzle, and long-diameter nozzle. As an example, the standard orifice plate is used as an example for description in the embodiment.

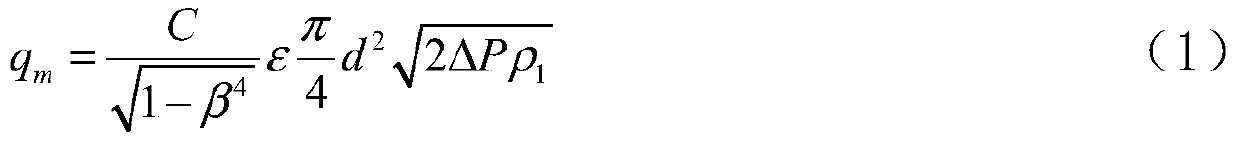

[0151] The differential pressure signal before and after the throttling device and the medium pressure signal before the throttling device are subjected to a first subtraction operation to obtain the first input value of the division operation; the output of the subtraction operation is divided by the medium pressure signal before the throttling device, obtain the pressure ratio τ as the third input value of the first function;

[0152] The medium pressure signal before the throttling device and the medium temperature signal before the throttling device are calculated through the first enthalpy entropy table to obtain the medium density ρ under the working sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com