Automatic capsule-coffee-making vending machine and capsule receiving mechanism thereof

A vending machine and coffee powder technology, applied in instruments, coin-operated equipment for distributing discrete items, beverage preparation devices, etc., can solve the problems of high cost, low degree of automation, poor compatibility, etc., and achieve convenient operation and connection , the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

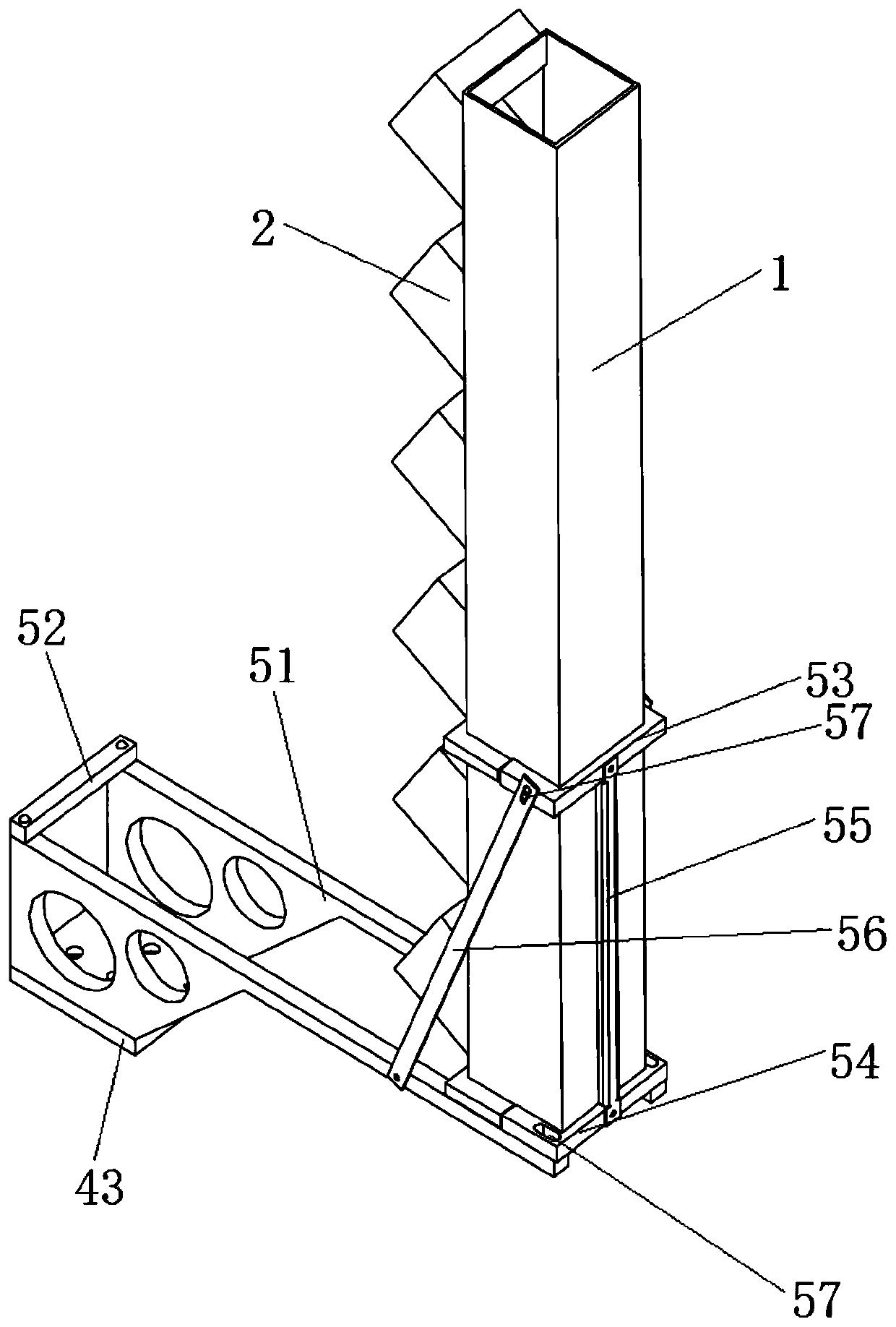

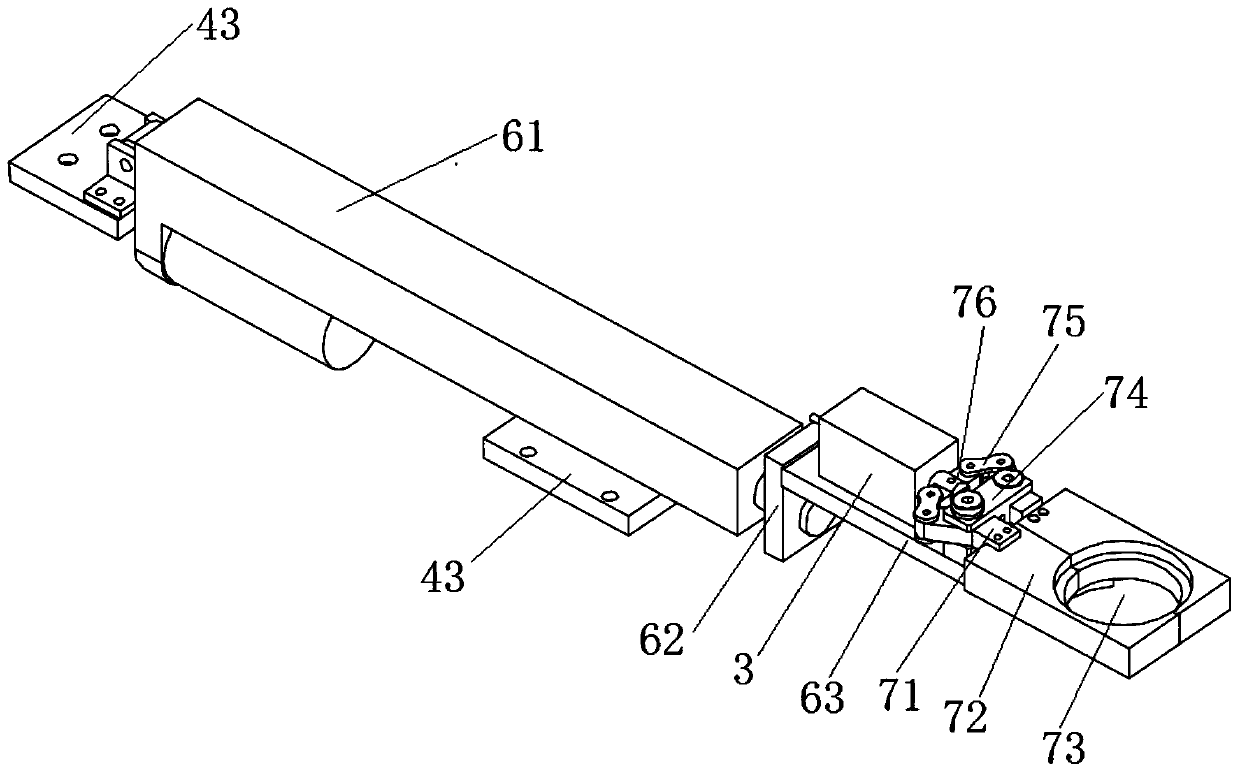

[0031] combine figure 1, the capsule receiving mechanism of a capsule coffee powder brewing automatic vending machine in this embodiment includes a vertically arranged capsule receiving channel 1, and the capsule receiving channel 1 is connected with the lateral movement mechanism through the cargo channel fixing mechanism, and through the lateral movement The mechanism drives the capsule cargo channel 1 to move so as to take capsules located in different columns; the left side of the capsule cargo channel 1 is evenly distributed along its height with a plurality of capsule distribution channels 2 arranged obliquely upward, and the plurality of capsule distribution channels Cargo channel 2 is used to take capsules located in different layers, so that the capsule distribution channel can take capsules located in different layers and different columns, which can meet the needs of different consumers with different tastes; the bottom of the capsule cargo channel 1 is provided for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com