Sensor microsystem package method and sensor microsystem

A packaging method and microsystem technology, applied in the direction of microstructure devices, processing microstructure devices, TV system components, etc., can solve the problems of poor versatility, low precision, and large volume of sensor microsystems, and achieve size reduction, High versatility and the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

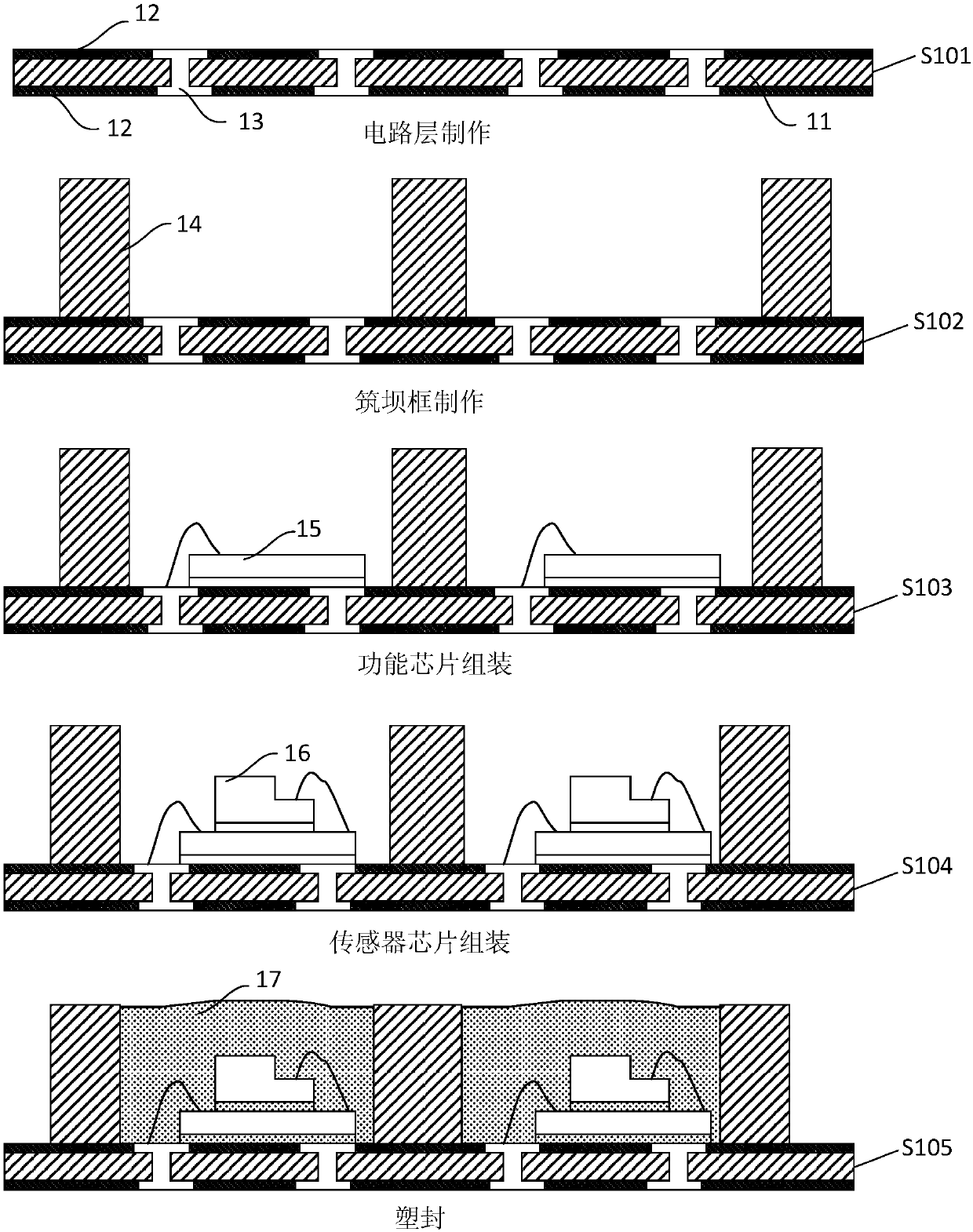

[0039] Such as figure 1 as shown, figure 1 It is a schematic workflow diagram of a sensor microsystem packaging method provided by an embodiment of the present invention, including:

[0040] Step S101: Fabricate a circuit layer 12 covering the substrate 11 on the front and back of the substrate 11, and fabricate a metal through hole 13 that penetrates the substrate 11 and is electrically connected to the circuit layer 12 on the back of the substrate 11;

[0041] Step S102: making a plurality of damming frames 14 for fixing the function chip 15 and the sensor chip 16 on the circuit layer 12 on the front side of the substrate 11;

[0042] Step S103: Between every two damming frames 14, assemble and electrically interconnect the back of the functional chip 15 and the top of the circuit layer 12, the functional chip 15 includes a processor chip or a controller chip;

[0043] Step S104: assembling and interconnecting the back of the sensor chip 16 and the front of the functional ...

Embodiment 2

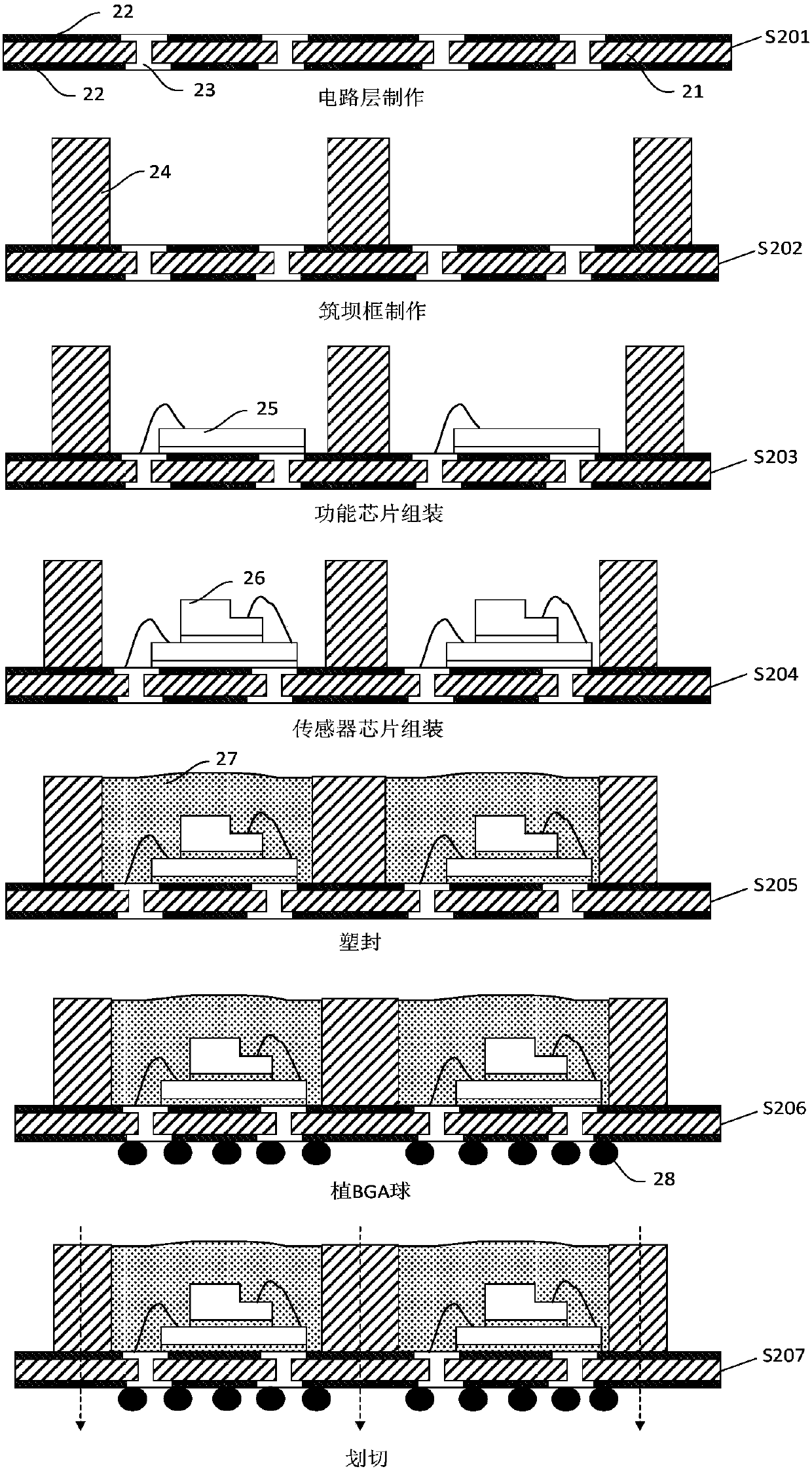

[0058] On the basis of Embodiment 1, Embodiment 2 further adds the fabrication of solder ball array balls, so the same parts as Embodiment 1 will not be repeated. Such as figure 2 as shown, figure 2 It is a schematic workflow diagram of a sensor microsystem packaging method provided by an optional embodiment of the present invention, including:

[0059] Step S201: Fabricate a circuit layer 22 covering the substrate 21 on the front and back of the substrate 21, and fabricate a metal through hole 23 that penetrates the substrate 21 and is electrically connected to the circuit layer 22 on the back of the substrate 21;

[0060] Step S202: making a plurality of damming frames 24 for fixing the function chip 25 and the sensor chip 26 on the circuit layer 22 on the front side of the substrate 21;

[0061] Step S203: Between every two damming frames 24, assemble and electrically interconnect the back of the functional chip 25 and the top of the circuit layer 22, and the functional...

Embodiment 3

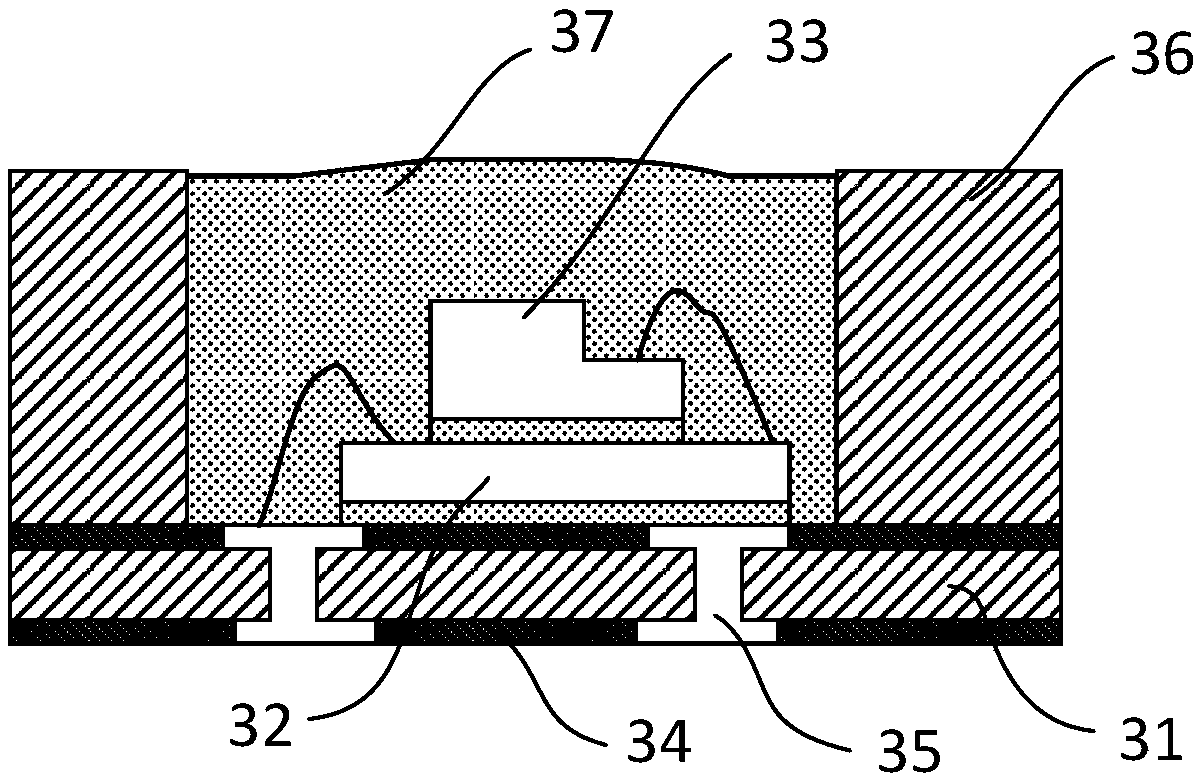

[0071] Embodiment 3 corresponds to Embodiment 1, so the same parts as Embodiment 1 will not be repeated. Such as image 3 as shown, image 3 It is a structural schematic diagram of a sensor microsystem provided by an embodiment of the present invention, including: a substrate 31, a functional chip 32 and a sensor chip 33, the functional chip 32 includes a processor chip or a controller chip, and the front and back of the substrate 31 are respectively set There is a circuit layer 34 covering the substrate 31. The back side of the substrate 31 is provided with a metal through hole 35 that penetrates the substrate 31 and is electrically connected to the circuit layer 34. The circuit layer 34 on the front side of the substrate 31 is provided with a plurality of chips 32 for fixing functions. and the damming frame 36 of the sensor chip 33, the back side of the functional chip 32 is electrically connected to the top of the circuit layer 34, the back side of the sensor chip 33 is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com