Temperature measurement system and method of internal portion of lithium ion battery

A lithium-ion battery, internal temperature technology, applied in thermometers, secondary batteries, measuring devices, etc., can solve problems such as airflow interference, insufficient precision, hard metal materials, etc., to achieve anti-electromagnetic interference, no electromagnetic interference, Good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

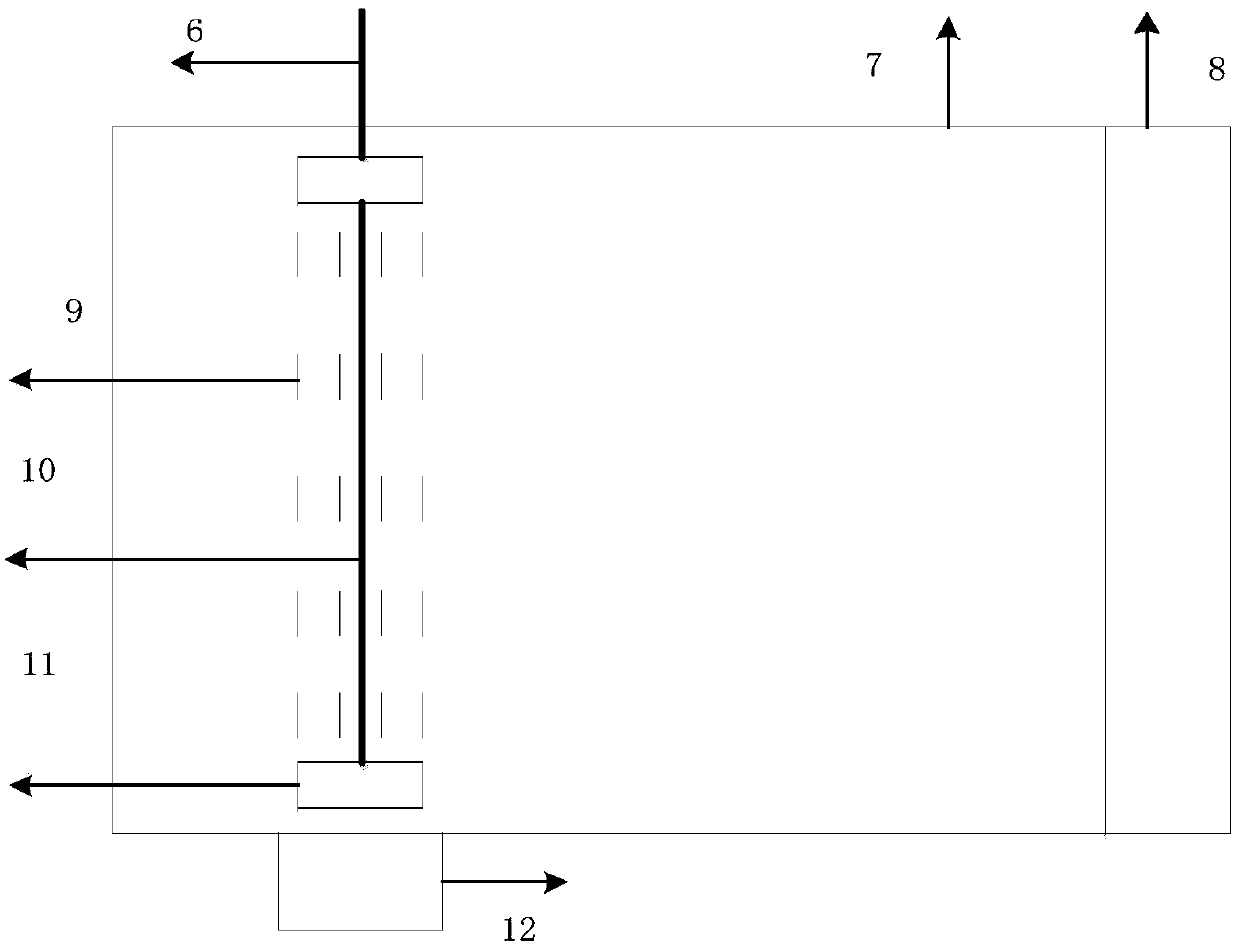

[0041] A kind of lithium-ion battery internal temperature measurement system provided by the invention comprises: fiber grating sensor, fiber grating demodulator and data processing module;

[0042] The fiber grating demodulator is connected to the data processing module; the fiber grating sensor includes a grating and an optical fiber;

[0043] The grating is pasted inside the lithium-ion battery;

[0044] An optical fiber located outside the lithium-ion battery is connected to a fiber grating interrogator.

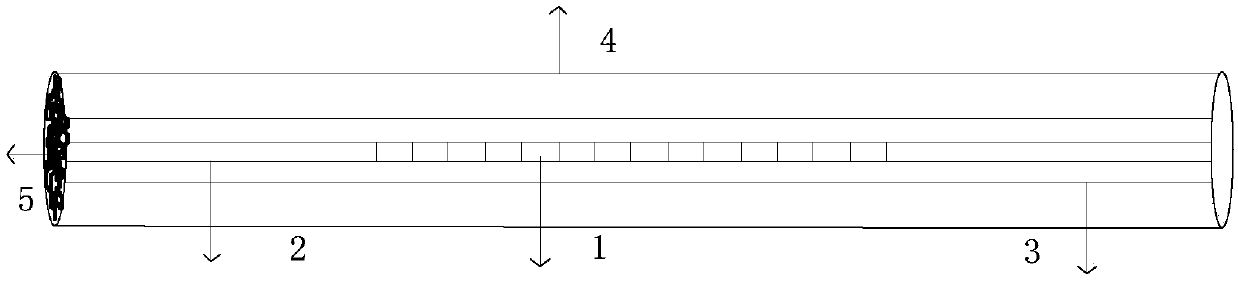

[0045] The specific structure of the fiber grating sensor is as follows: figure 1 As shown, it includes: 1 grating area, 2 fiber core, 3 fiber coating, 4 neutral hard sealing glass tube.

[0046] 1 The grating area, 2 one end of the fiber core and 3 the coating layer of the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com