High-tenacity belt core used for conveying belt

A technology for strong belts and conveyor belts, applied in the field of high-strength belt cores for conveyor belts, which can solve the problems of easy delamination and strength of conveyor belts, and achieve the effects of high strength, reduced number of layers, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

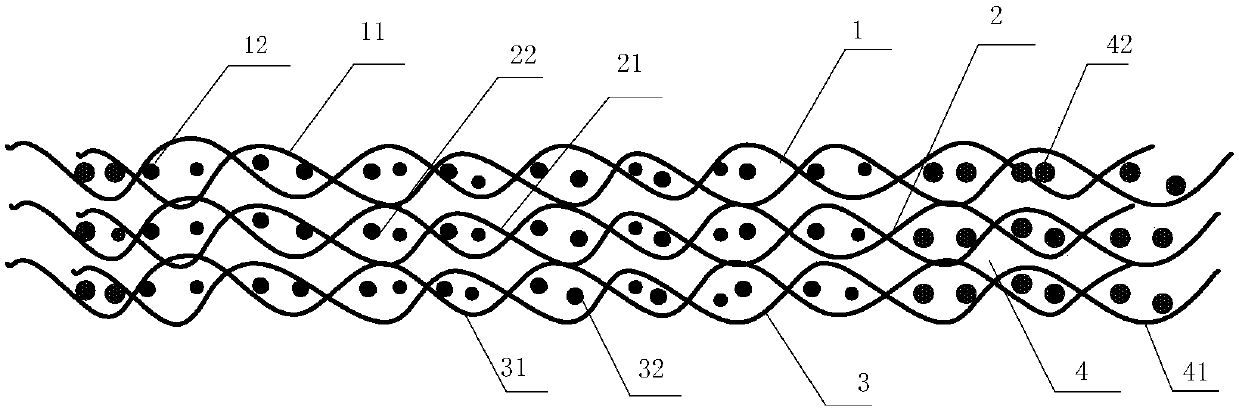

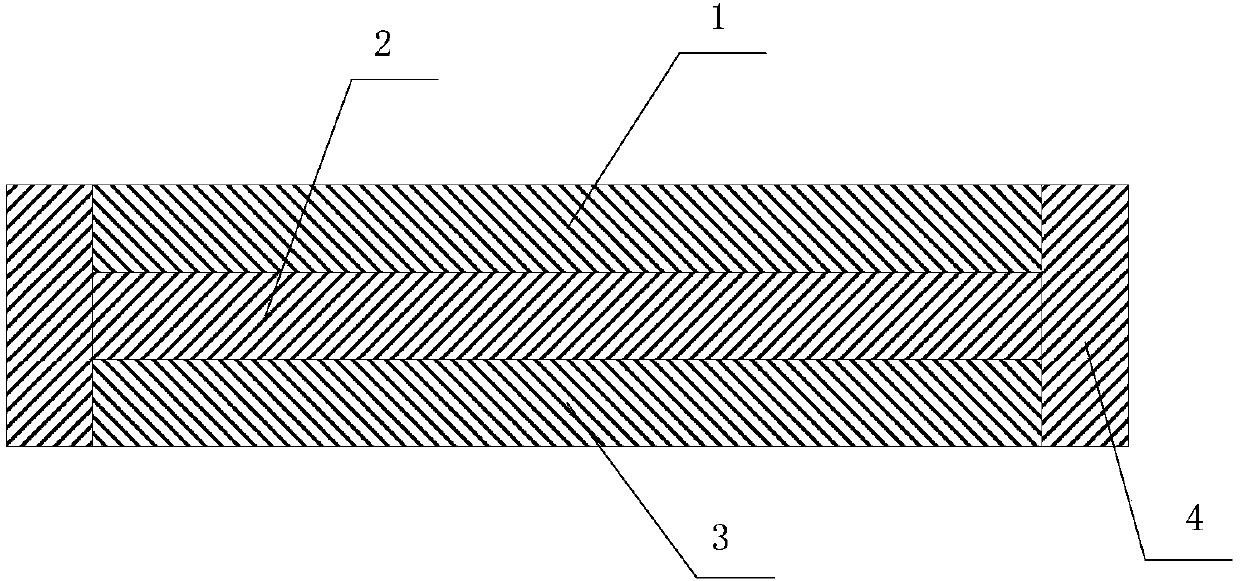

[0025] A high-strength belt core for a conveyor belt, such as figure 1 , including an upper braided layer 1, a middle braided layer 2, a lower braided layer 3 and a side braided layer 4, the middle braided layer 2 is between the upper braided layer 1 and the lower braided layer 3, and the edge braided layer 4 is on the upper braided layer 1 , the sides of the middle braided layer 2 and the lower braided layer 3;

[0026] The upper braided layer 1 includes upper warp threads 11 and upper weft threads 12. The upper layer warp threads 11 alternately weave between adjacent two layers around the upper layer weft threads 12. The peak and trough spans of the upper layer warp threads 11 alternately weave up and down are 1-3 upper layer weft threads 12. , the upper layer warp thread 11 is polyester fiber, the number of shares of polyester fiber is 5 shares, the twist is 50-70 turns / meter, and the upper layer weft thread 12 is a ply thread;

[0027] The middle braided layer 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com