Turbocharger lubricating oil return device

A technology of turbocharger and lubricating oil, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of limited oil and gas separation effect, poor oil return, insufficient oil return pressure, etc., to reduce oil consumption , The effect of reducing maintenance costs and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

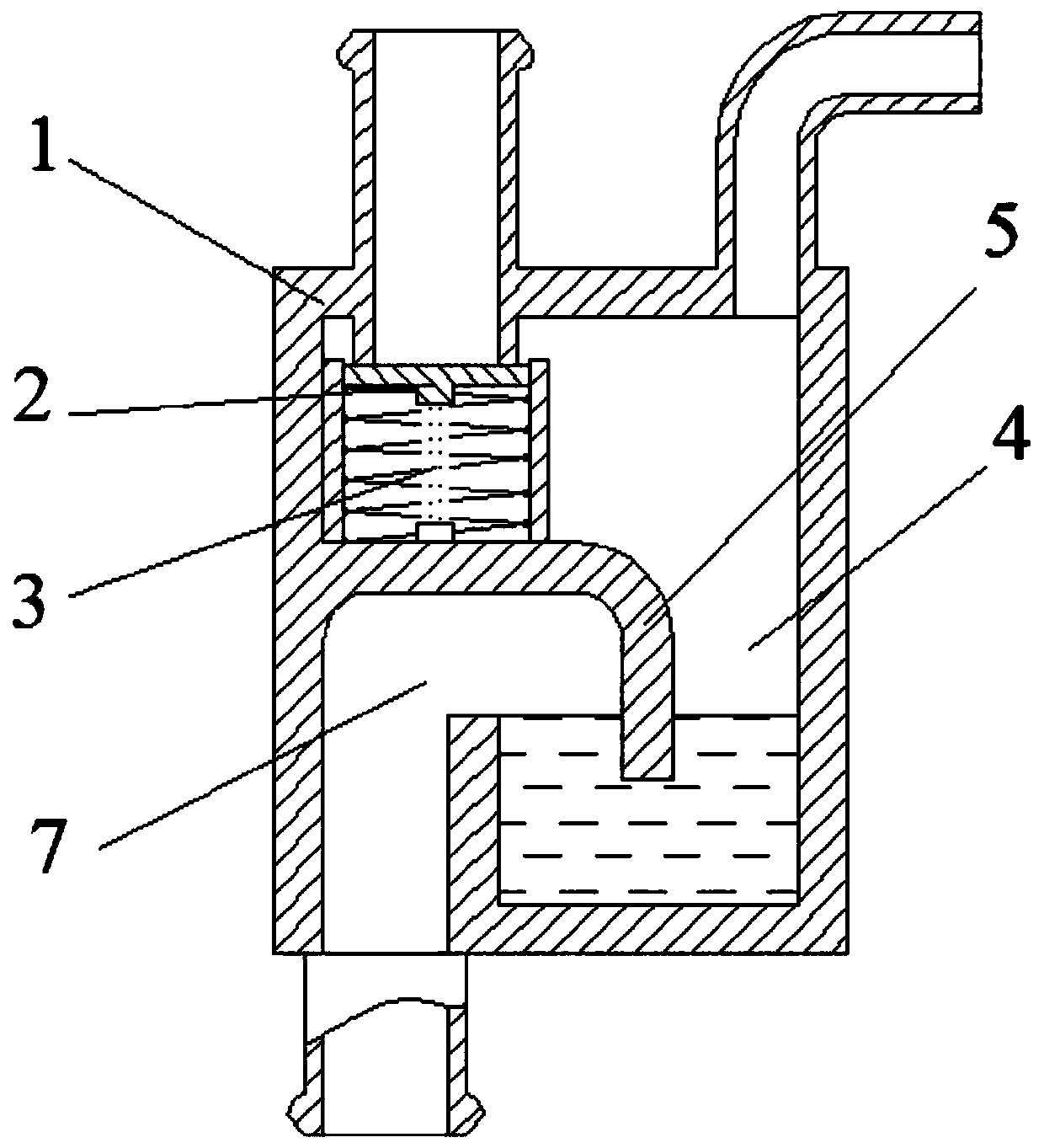

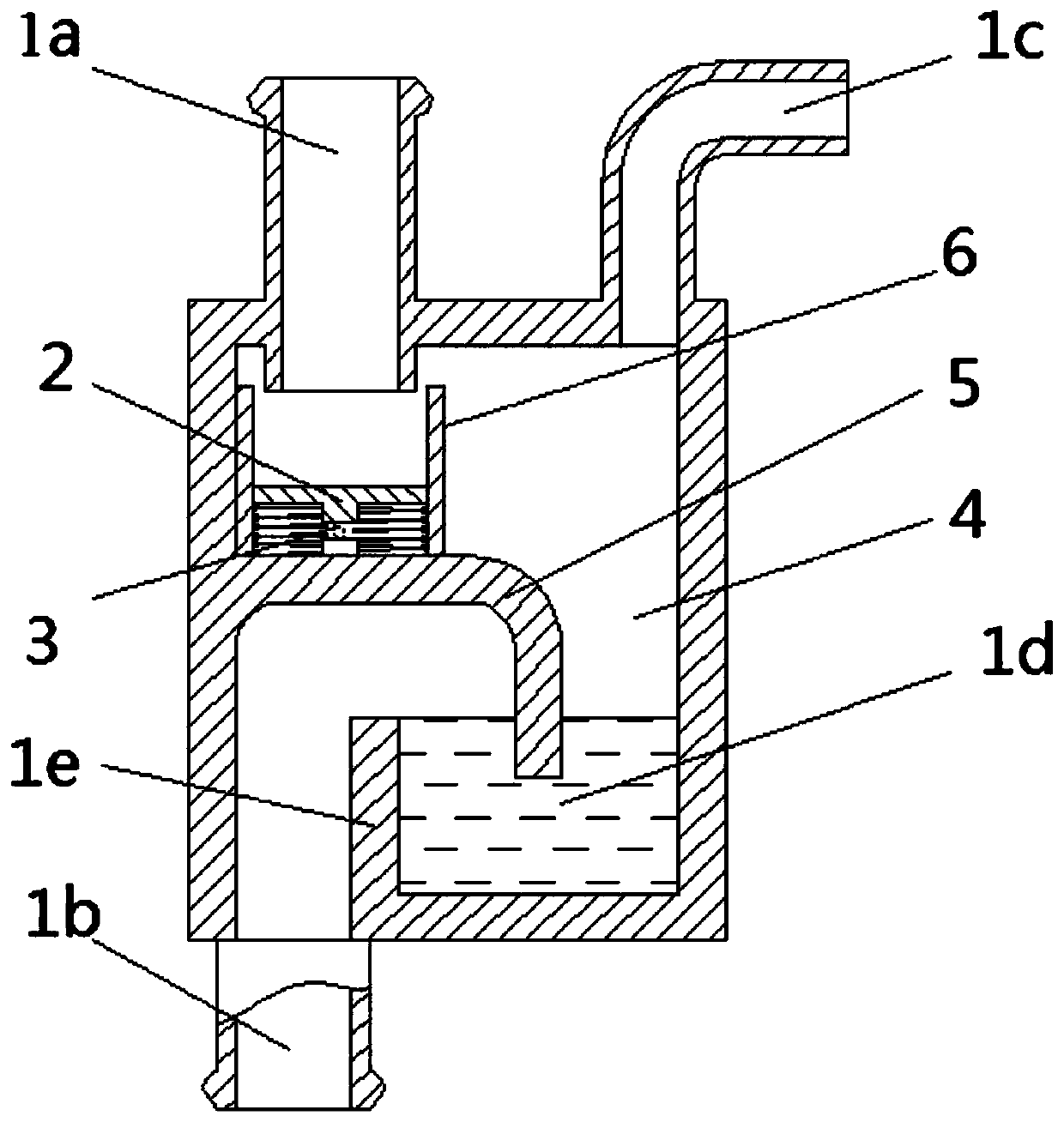

[0021] Figure 1~2 The turbocharger lubricating oil return device shown in includes an oil return cavity 1, and the oil return cavity 1 has an oil inlet 1a connected to the middle of the turbocharger for receiving lubricating oil and for Guide the lubricating oil to the oil outlet 1b and vent 1c in the engine oil pan. The vent 1c is located on the upper part of the oil return cavity and is directly connected to the atmosphere. It can also be connected to the pipeline of the crankcase ventilation system or the turbocharger. The air intake pipeline is connected to connect to the atmosphere indirectly.

[0022] There is an oil storage chamber 4 inside the oil return chamber 1, a U-shaped oil storage tank 1d with an upward opening is arranged at the lower part of the oil storage chamber 4, and an overflow baffle 1e is provided at the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com