a shifting device

A shifting device and shifting mechanism technology, applied in the direction of transmission control, toothed components, belts/chains/gears, etc., can solve the problem of difficult adjustment of gear control speed, influence of processing and installation accuracy, and repeated positioning Low precision and other problems, to achieve the effect of simple structure, fast response and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

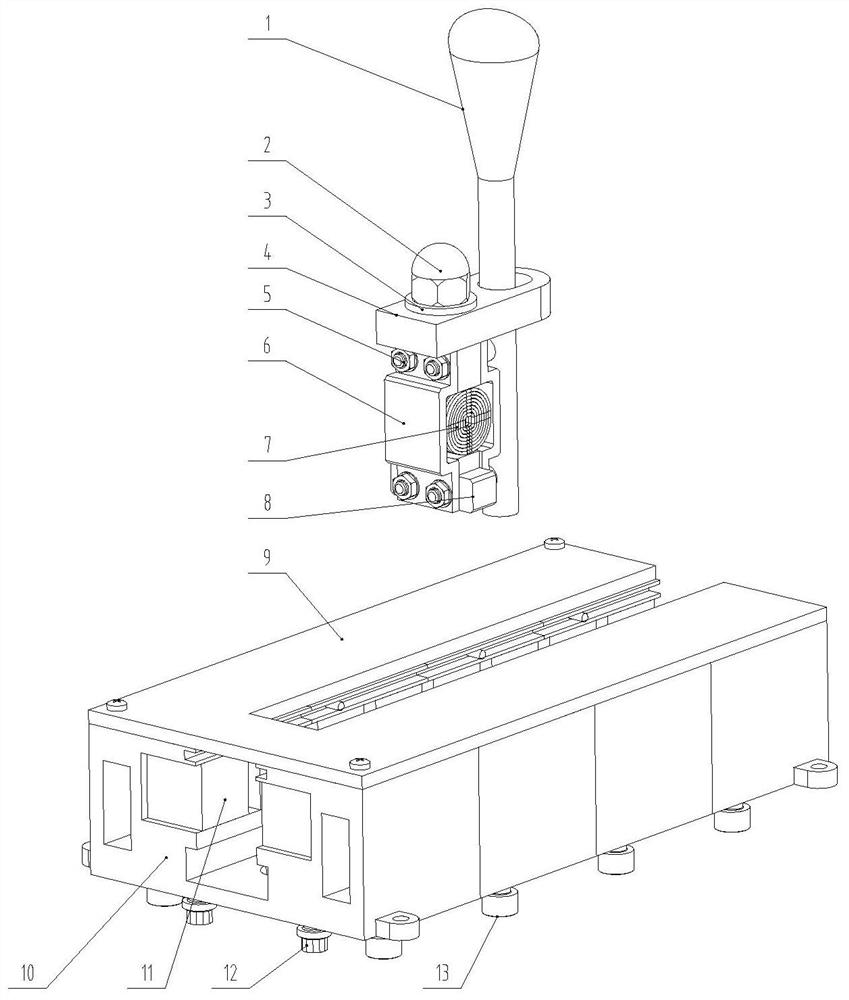

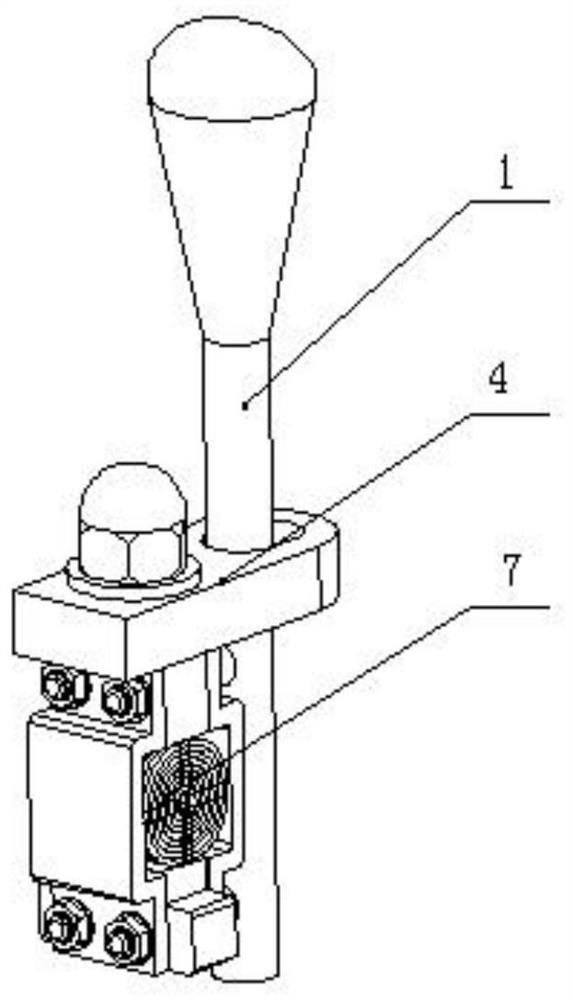

[0032] This embodiment provides a gear shifting device, including a linear gear shift mechanism 14; the linear gear shift mechanism 14 includes: a stator assembly, a mover assembly and a stop rod 1, the stop rod 1 passes through the mover subassembly, and the mover subassembly Sliding in the stator assembly, driving the stop rod 1 to move;

[0033] The stator assembly includes: a control circuit board 9, a stator base 10, a permanent magnet 11, and a movable limit sensor 16; the control circuit board 9 is placed on the stator base 10, and the stator base 10 is provided with a guide groove, so The above-described guide grooves include guide grooves I18, guide grooves II19 and guide grooves III20 arranged from top to bottom, and guide groove II19 is placed between guide grooves I18 and guide grooves III20; permanent magnets 11 are symmetrically distributed in guide grooves II19, which can be The movement limit sensor 16 is placed in the guide groove I18, the magnetic pole direct...

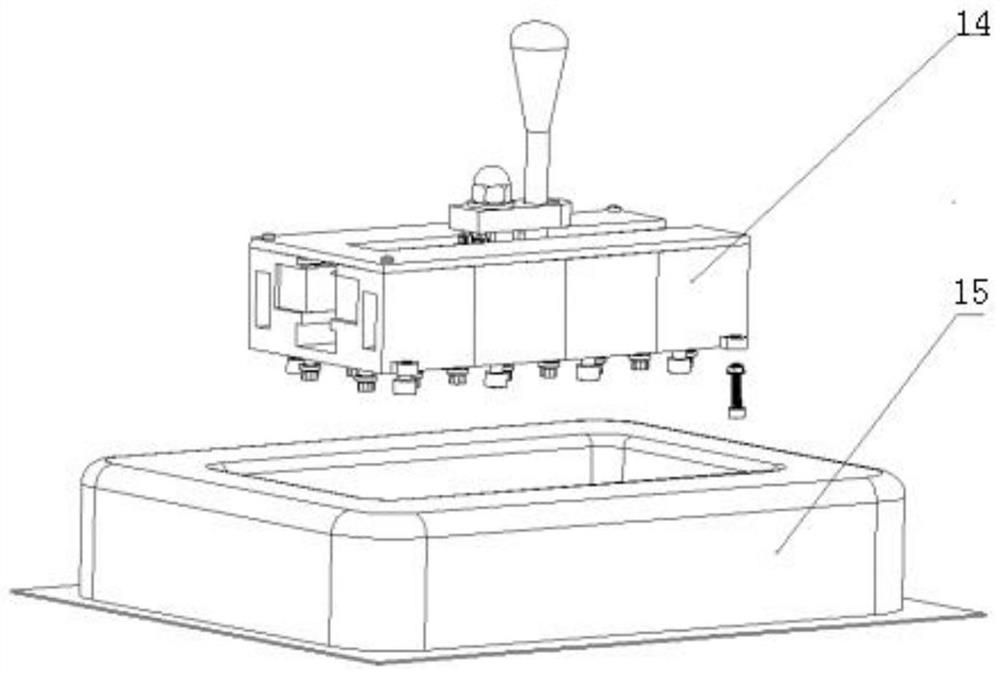

Embodiment 2

[0039] The linear shift mechanism 14 described in embodiment 1 is installed and fixed in the hollow armrest box 15, and the shift dust cover is removed earlier before installation, and the figure 2 A plurality of fixing bolts shown fix the base of the linear shift mechanism 14 in the center control armrest box 15 inside.

[0040] The permanent magnet 11 is fixed on the stator base 10. The permanent magnet is a 20mmx20mmx20mm square magnetic pole. The direction of the magnetic pole is perpendicular to the direction of the guide groove II19. Fixed, easy to move and adjust the position of the permanent magnet. The mover slider 8 of the mover assembly and the stator assembly is matched with the guide groove III20, and lubricating oil is applied in the guide groove III20, so that the mover slider 8 can slide freely in the guide groove III20;

[0041] The mover coil 7 can move linearly under the magnetic field after being energized, thereby driving the blocking rod 1 to move back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com