Explosion loading electric measurement-dynamic photoelasticity hybrid experiment system and method

A technology of dynamic photoelasticity and experimental system, applied in the field of experimental mechanics research, can solve the problem that the law of stress field change at the tip of the moving crack has not been carried out, and achieve the effect of wide application value, simple measurement equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

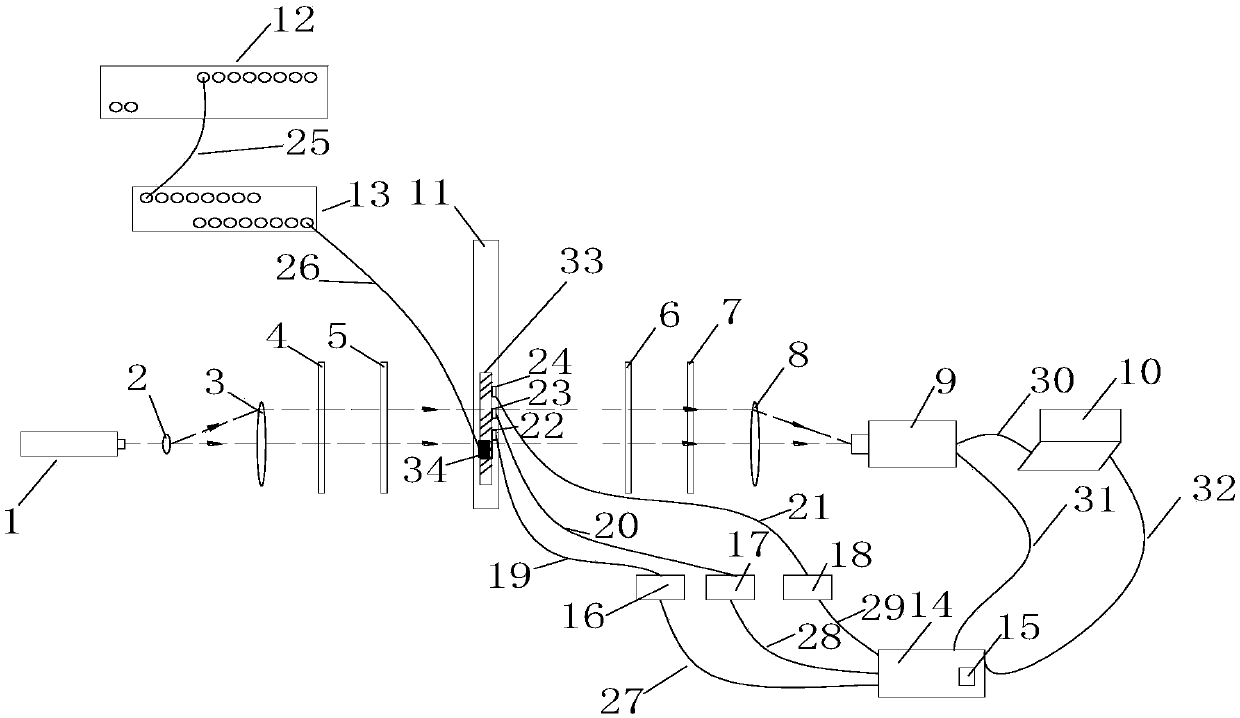

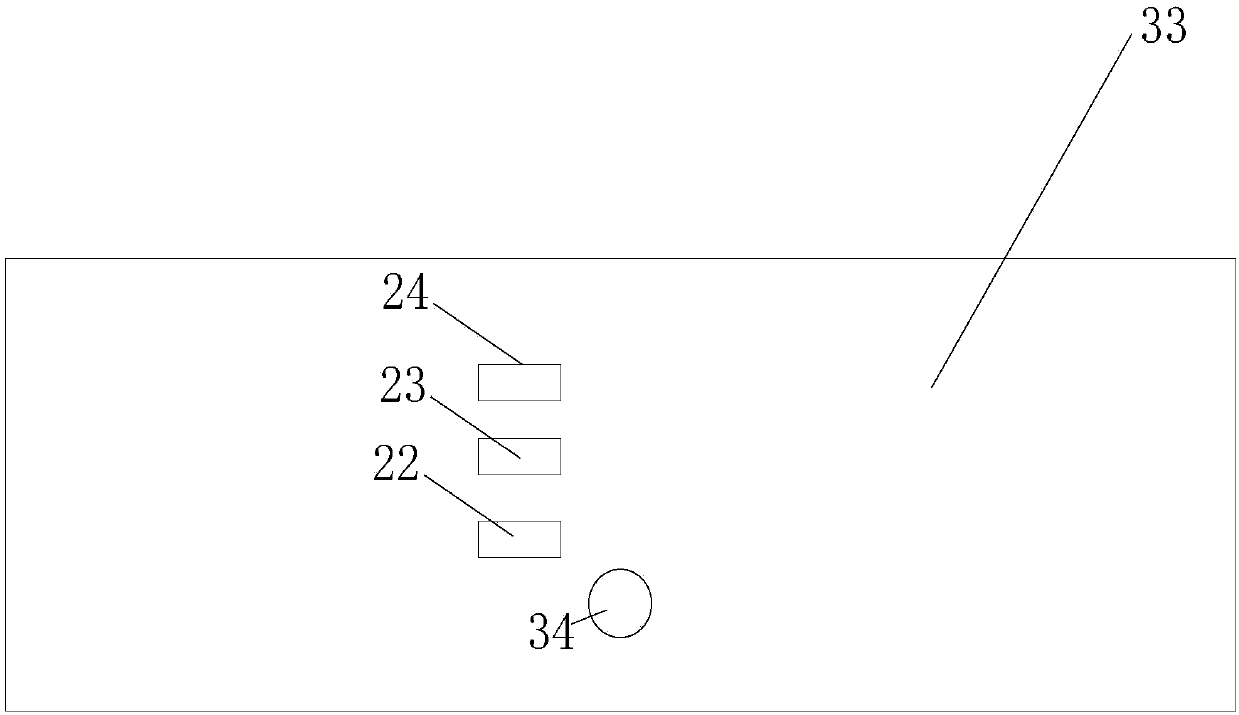

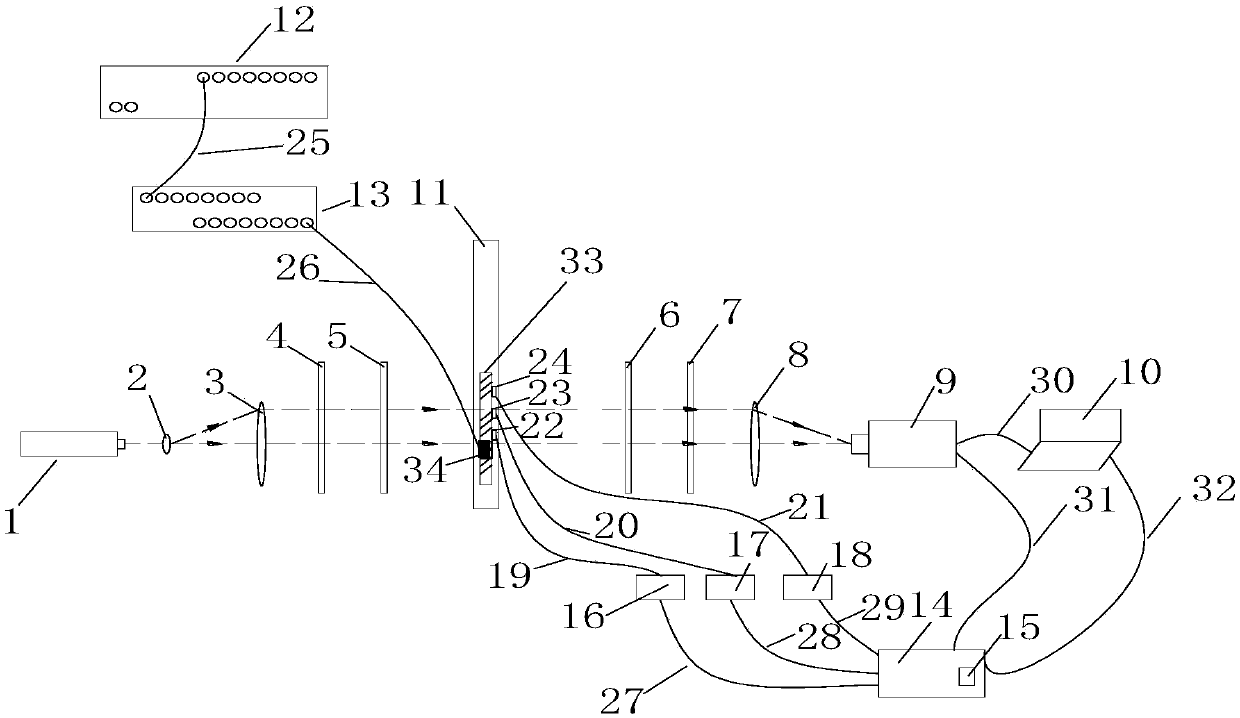

[0026] refer to figure 1 , explosive loading electrical measurement-dynamic photoelastic hybrid experimental system, including laser light source 1, beam expander 2, convex lens A3, polarizer A4, quarter-wave plate A5, quarter-wave plate B6, polarizer B7, Convex lens B8, high-speed camera 9, computer 10, experimental loading platform 11, delay and controller 12, multi-channel pulse igniter 13, ultra-dynamic strain gauge 14, data acquisition instrument 15, test piece 33, explosive package 34, bridge Boxes 16-18, signal wires 25-32, shielding wires 19-21, strain gauges 22-24; wherein, the data acquisition instrument 11 is located inside the ultra-dynamic strain gauge 10.

[0027]In the described experimental system, before the experiment starts, a certain strain gauge on the test piece 33 is set as the trigger strain gauge through the computer 10 according to the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com