Formable anti-glare polymer film

A polymer film, anti-glare technology, used in polyurea/polyurethane coatings, instruments, anti-reflection coatings, etc., to achieve the effect of good molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

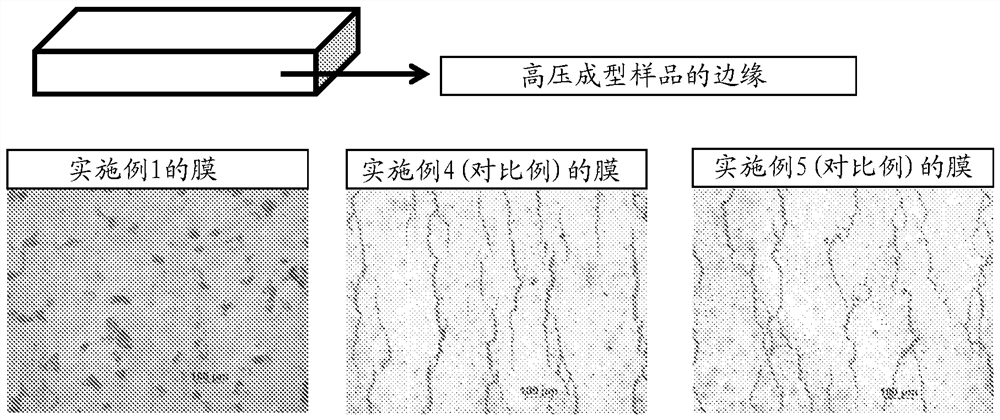

Embodiment 1

[0152] Approximately 40.65 grams of UA122P (a difunctional urethane acrylate supplied by Shin Nakamura, Japan) was weighed into a container and 30 grams of 1-methoxy-2-propanol was added. The mixture was stirred until a homogeneous solution appeared. To this solution was added 27.18 g of PETIA (pentaerythritol triacrylate from Allnex S.à r.l) and 0.11 g of Additol TM VXL 4930 (from Allnex S.à r.l). The mixture was stirred for an additional 15 minutes to ensure a homogeneous solution, followed by the addition of 2.06 g of Irgacure TM 184 (photoinitiator from BASF SE). The theoretical crosslink density is calculated to be 1.81·10 -3 .

[0153] Apply the liquid formulation to Makrofol as described above on the roughened PMMA surface TM 908 base. The breaking elongation of this coating film was 3.9%.

Embodiment 2

[0154] Embodiment 2 (comparative example):

[0155] A membrane has been prepared as described in Example 1, but the membrane used is Makrofol TM SR253.

[0156] The breaking elongation of this coating film was 3.5%. This coating film did not exhibit antiglare properties.

Embodiment 3

[0157] Embodiment 3 (comparative example):

[0158] Approximately 27.18 grams of UA122P (urethane acrylate supplied by Shin Nakamura, Japan) was weighed into a container and 30 grams of 1-methoxy-2-propanol was added. The mixture was stirred until a homogeneous solution appeared. To this solution was added 40.65 g of PETIA (pentaerythritol triacrylate from Allnex S.à r.l) and 0.11 g of Additol TM VXL 4930 (from Allnex S.à r.l). The mixture was stirred for an additional 15 minutes to ensure a homogeneous solution, followed by the addition of 2.06 g of Irgacure TM 184 (photoinitiator from BASF SE). The theoretical crosslink density was calculated to be 2.71·10 -3 .

[0159] Apply the liquid formulation to Makrofol as described above on the roughened PMMA surface TM 908 base. The breaking elongation of this coating film was 2.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com