Electronic cigarette atomizer

The technology of an electronic cigarette atomizer and atomizer, which is applied in the field of electronic cigarettes, can solve problems such as the deterioration of the quality of smoke taste, the small amount of smoking smoke, and the cracking of electronic cigarette oil, so as to avoid the risk of cracking, increase the amount of smoke, and improve the quality of smoke. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

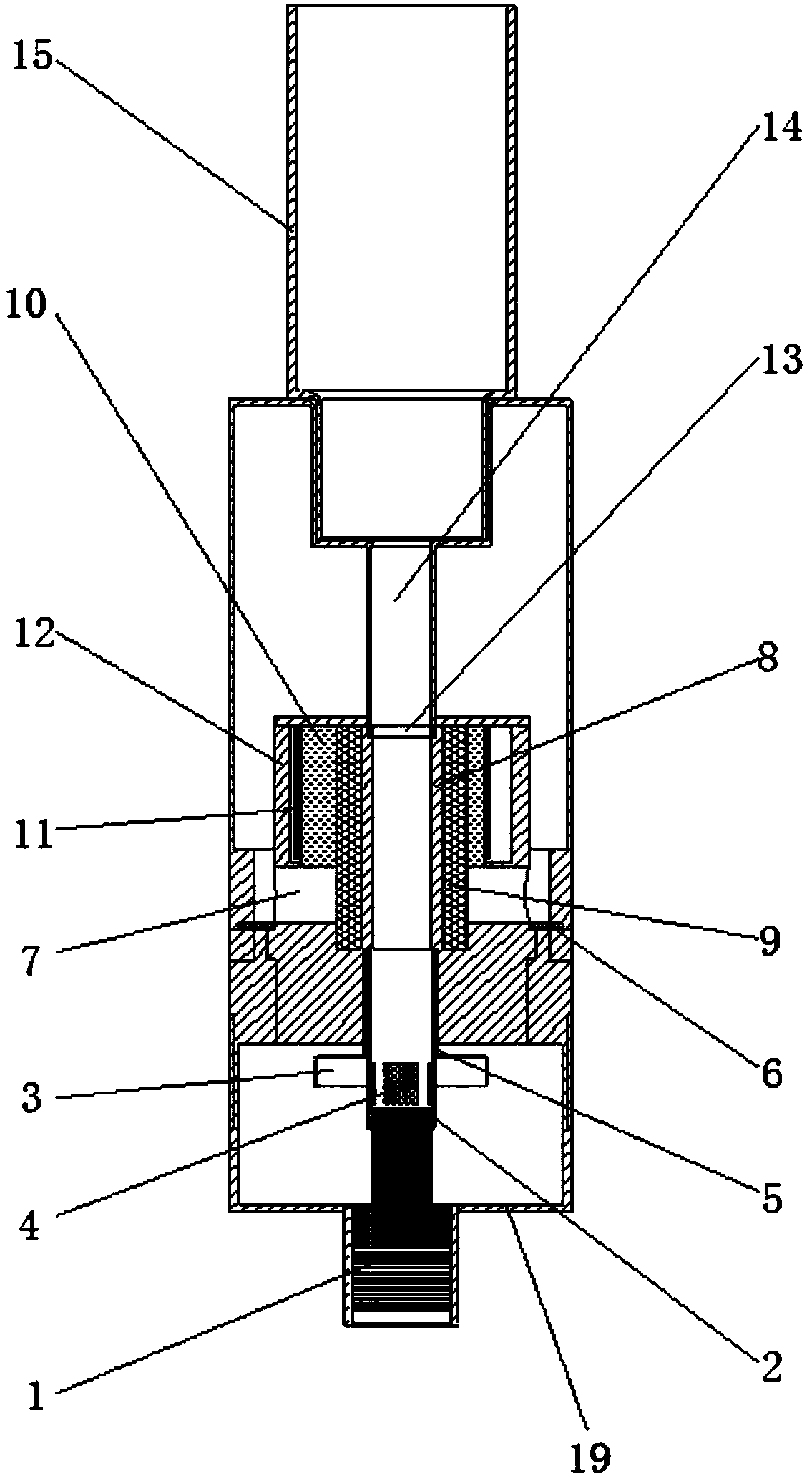

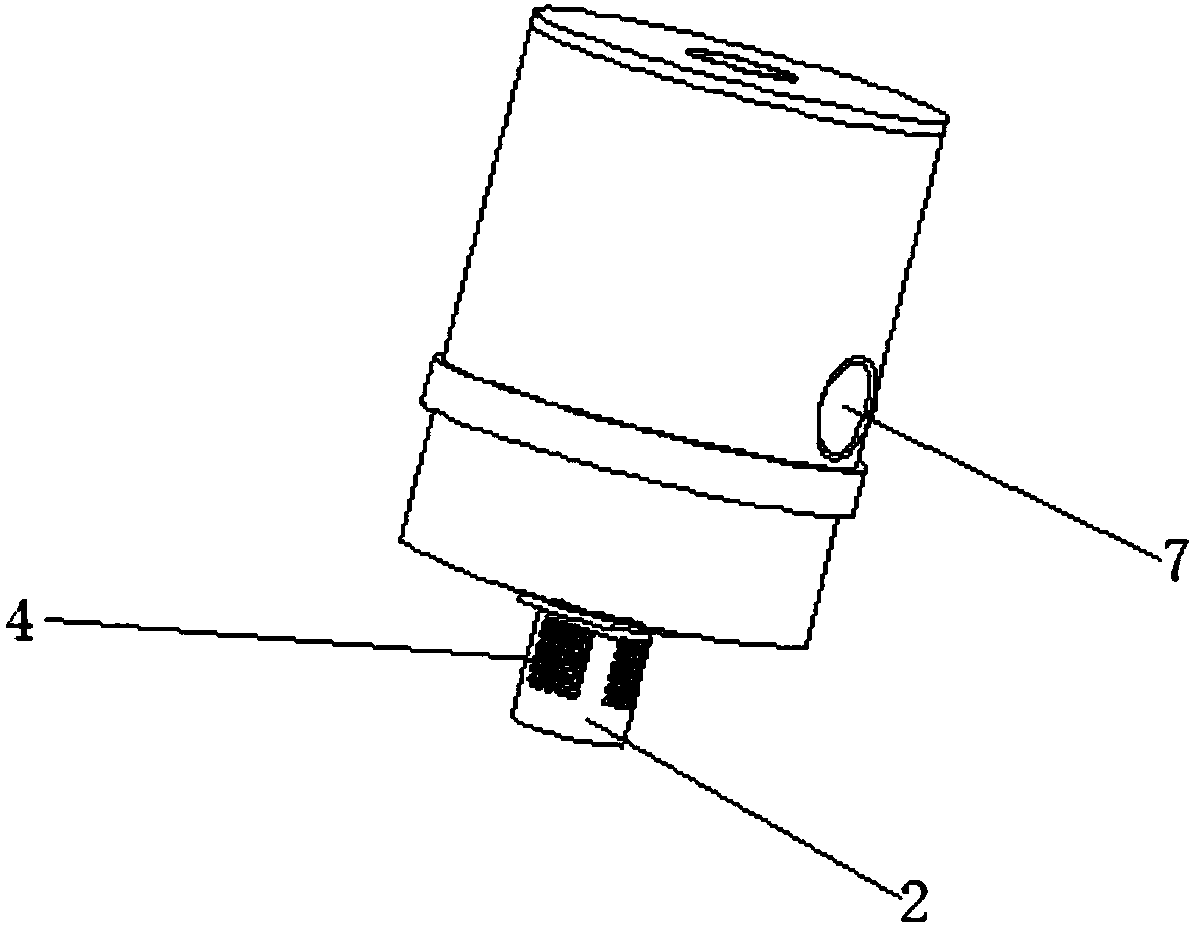

[0030] Such as Figure 1 to Figure 7 As shown, the electronic cigarette atomizer according to Embodiment 1 of the present invention includes an atomizing core, a heating element 11 , an oil carrying element 9 and an oil guiding element 7 .

[0031] The atomizing core has an atomizing cavity and several through holes, and the atomizing cavity communicates with the air flow channel 14 and the suction nozzle 15; the heating element 11 and the oil carrying element 9 are arranged on the In the atomizing core, the oil carrying element 9 communicates with the atomizing chamber; the oil guiding element 7 is arranged in the through hole and communicates with the oil storage chamber 18 and the oil carrying element 9 respectively.

[0032] The atomizing core, the heating element 11 , the oil carrying element 9 and the oil guiding element 7 will be described respectively below.

[0033] (1) atomizing core

[0034] Such as figure 1 As shown, the atomizing core is surrounded by an atomiz...

Embodiment 2

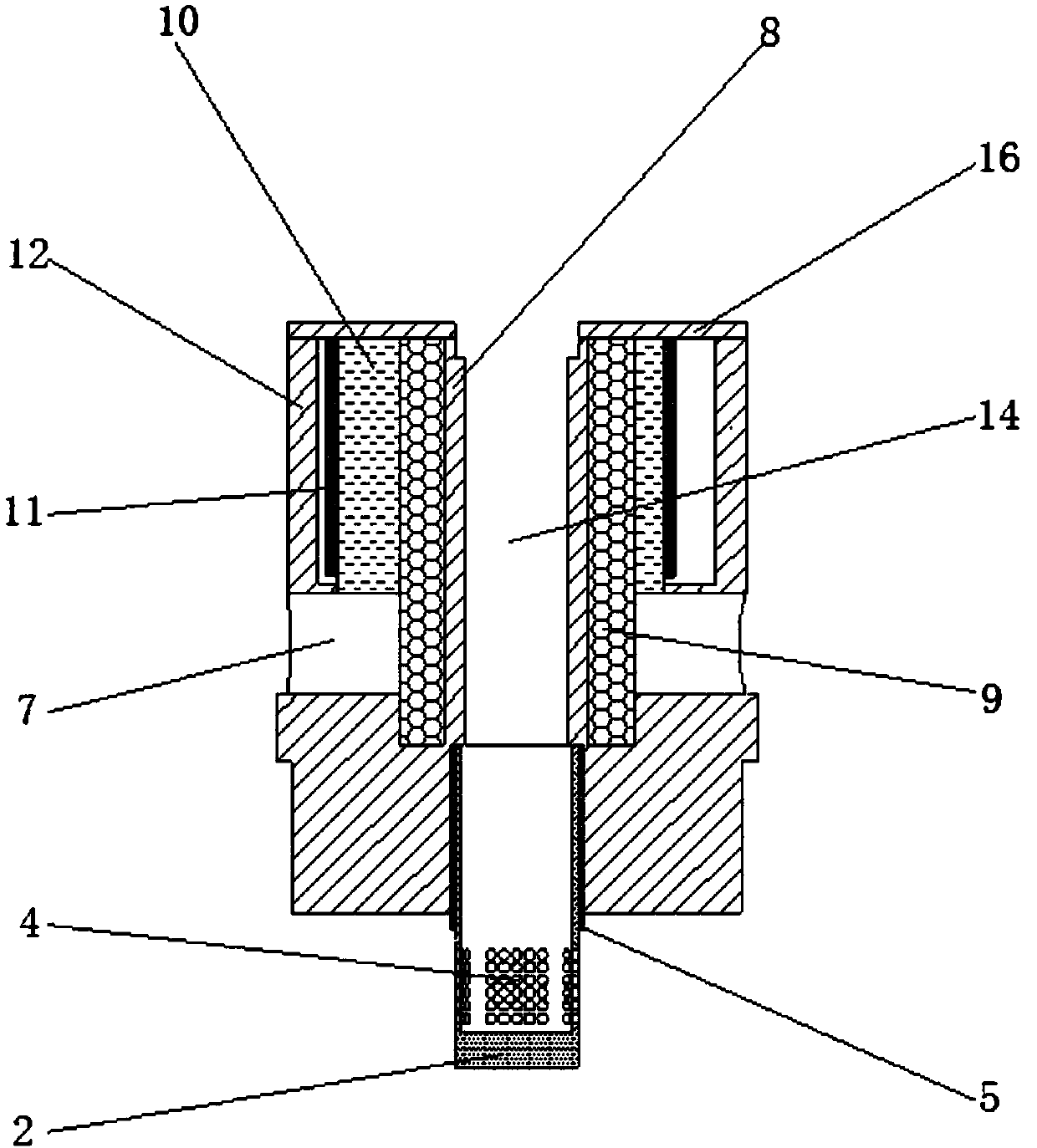

[0066] The difference from the first embodiment is that a heat insulating layer 23 is provided between the heating element 11 and the atomizing core housing 12 to prevent the heat of the heating element 11 from spreading outward.

[0067] Such as Figure 8-10 As shown, the electronic cigarette atomizer according to the second embodiment of the present invention includes an atomizing core. The atomizing core includes a heating element 11 composed of a micro heater, the heating element 11 is connected to the oil carrying element 9, and the oil carrying element 9 communicates with the oil storage chamber 18 through the oil guiding element 7; the oil carrying element 9 communicates with the atomizing chamber, and the atomizing chamber communicates with the airflow channel 14 and the suction nozzle 15 . The oil carrying element 9 is made of organic cotton material, and the oil guiding element 7 is made of organic cotton material. The atomizer is made of materials such as stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com