A crankshaft polishing support device with self-cleaning function

A support device and crankshaft technology, applied in grinding/polishing safety devices, grinding drive devices, filing/filing devices, etc., can solve problems such as inability to adjust the crankshaft, inconvenient clamping and fixing of the crankshaft, and lack of cleaning functions , to achieve the effect of preventing slipping and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

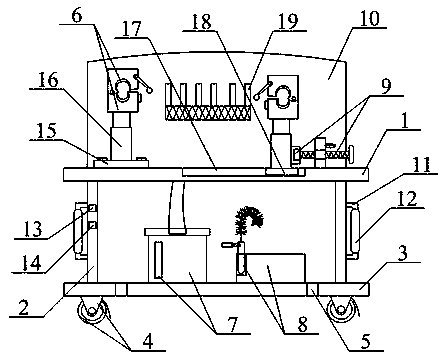

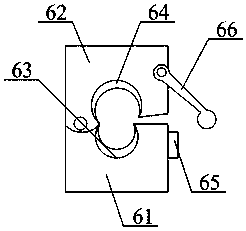

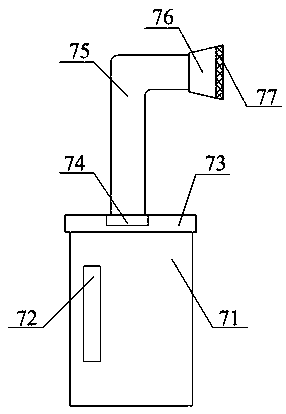

[0037] as attached figure 1 to attach figure 2 As shown, the present invention provides a crankshaft polishing support device with self-cleaning function. Card seat structure 6, filter and adsorption waste cleaning cover structure 7, crankshaft grinding and trimming rod structure 8, cylinder push rod ejector structure that can fix the oil pot 9, rear protective baffle 10, hand push handle 11, anti-slip sleeve 12. Lifting control switch 13, cleaning control switch 14, first fixed seat 15, lifting cylinder 16, moving chute 17, second fixed seat 18 and magnet bar 19, and one end of the support column 2 is bolted to the The four corners of the lower surface of the upper supporting horizontal plate 1, and the other end bolts are connected to the four corners of the upper surface of the lower supporting horizontal plate 3; the moving wheels 4 are respectively bolted to the four corners of the lower surface of the lower supporting horizontal plate 3; The fixed through-holes 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com