A kind of tricyclopropyl compound, its preparation method and application

A compound, cyclopropyl technology, applied in the field of new aerospace fuel, can solve the problems of unfavorable industrial production, high production cost, complicated preparation method, etc., and achieve the effects of improving mass specific impulse and effective load, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of tricyclopropyl compound

[0027] (1) Preparation of zinc carbenes

[0028] in N 2 Atmosphere, at -15°C, add 15mL of CH 2 Cl 2 , 15mL of ZnEt 2 (15mmol) reagent, and CF containing 15mmol 3 CH of COOH 2 Cl 2 Solution 15mL, stirred for 20min; continue to add 15mmol of CH 2 I 2 CH 2 Cl 2 Solution 15mL, stirred for 20min to obtain zinc carbene body CF 3 COOZnCH 2 I.

[0029] (2) Cyclopropanation of myrcene to obtain tricyclopropyl compound

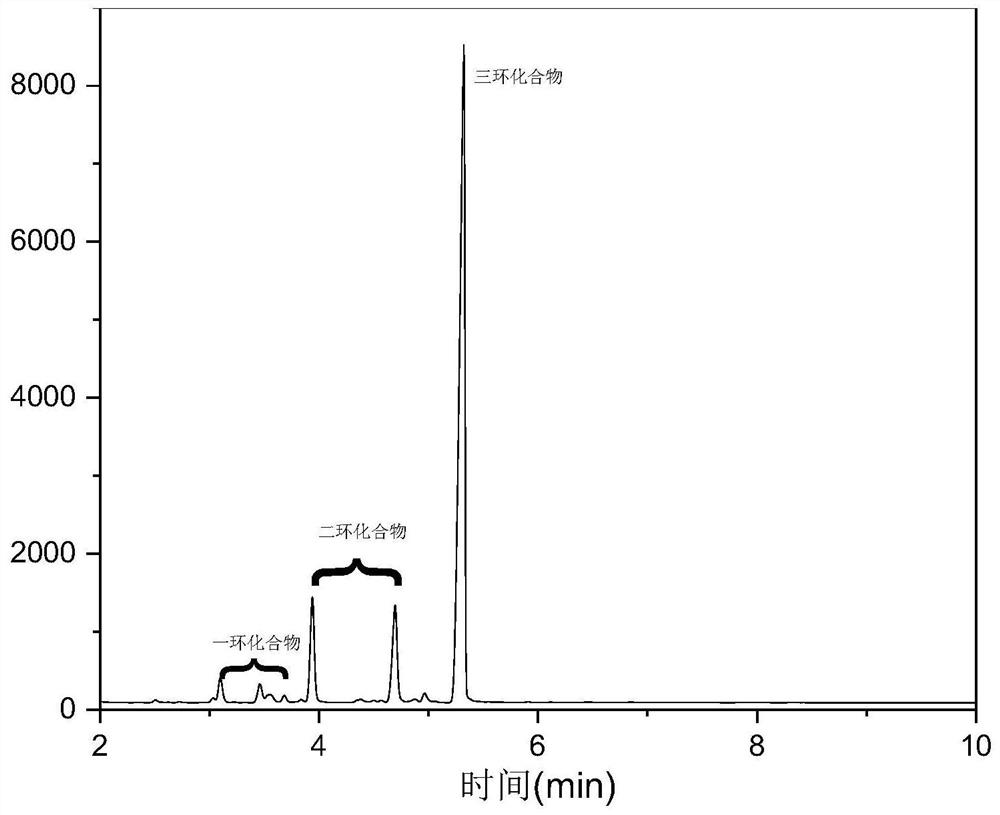

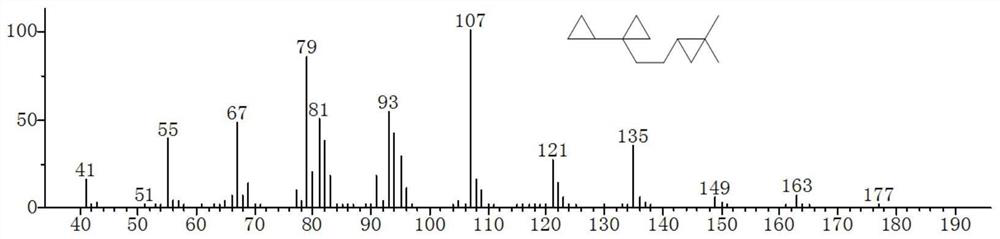

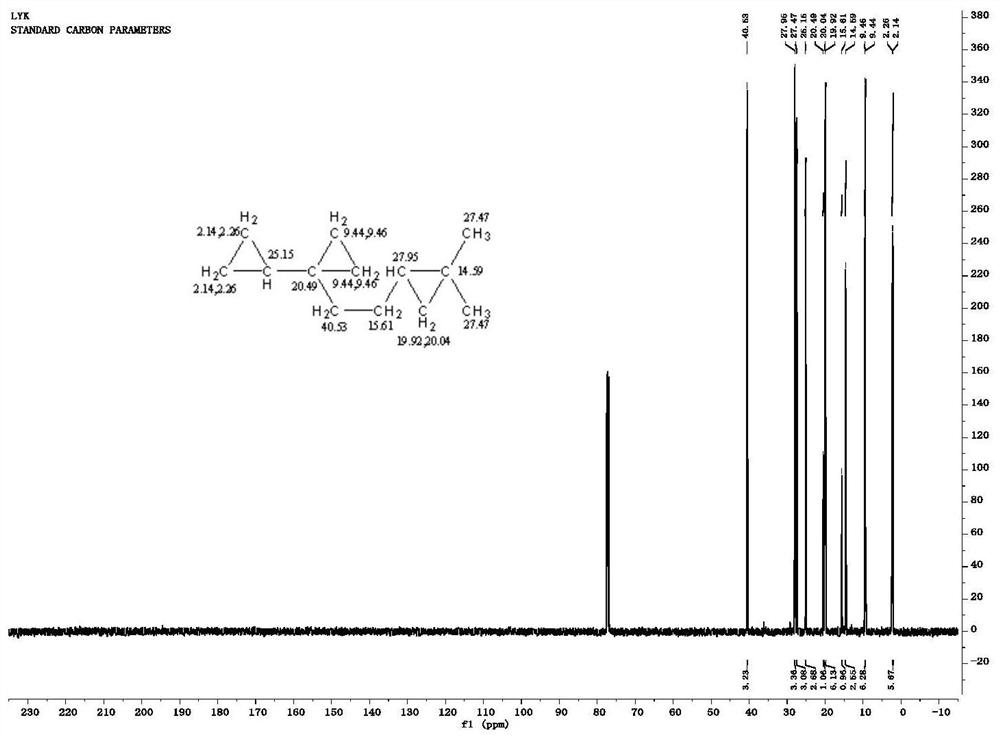

[0030] Add 5 mmol of myrcene in CH to the above zinc carbene 2 Cl 2 Solution 15mL, stirred at 25°C for 6h to obtain a mixture containing cyclopropane structure. After analysis, wherein the content of tricyclopropyl compound is 69.8wt% (note: remaining 31.2wt% is unsaturated one ring and two cyclocyclopropyl compounds), analysis result is as attached Figure 1-2 shown. After separation and purification, the tricyclopropyl compound is obtained, and the analysis results are as attached Fi...

Embodiment 2-15

[0033] Example 2-15 The reaction steps are the same as in Example 1, except that the reaction conditions include: reaction time, reaction temperature, organic acid reagent type, organic solvent type, and the molar ratio of zinc carbene to myrcene, etc., as shown in Table 1; The yields (wt%) of cyclopropyl compounds are shown in Table 1.

[0034] Table 1 Example 2-15

[0035]

[0036] The mixture obtained in Examples 2-15 can be used as aerospace fuel after separation and purification or compounded with other high-density aerospace fuels to improve the performance of aerospace fuels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com