Spraying-free ABS composite material suitable for FDM and preparation method thereof

A composite material and spray-free technology, which is applied in the direction of additive processing, etc., can solve the problems of unsatisfactory color requirements, high cost, and health damage to operators, so as to shorten the time for finished products, benefit health and safety, and avoid spraying The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

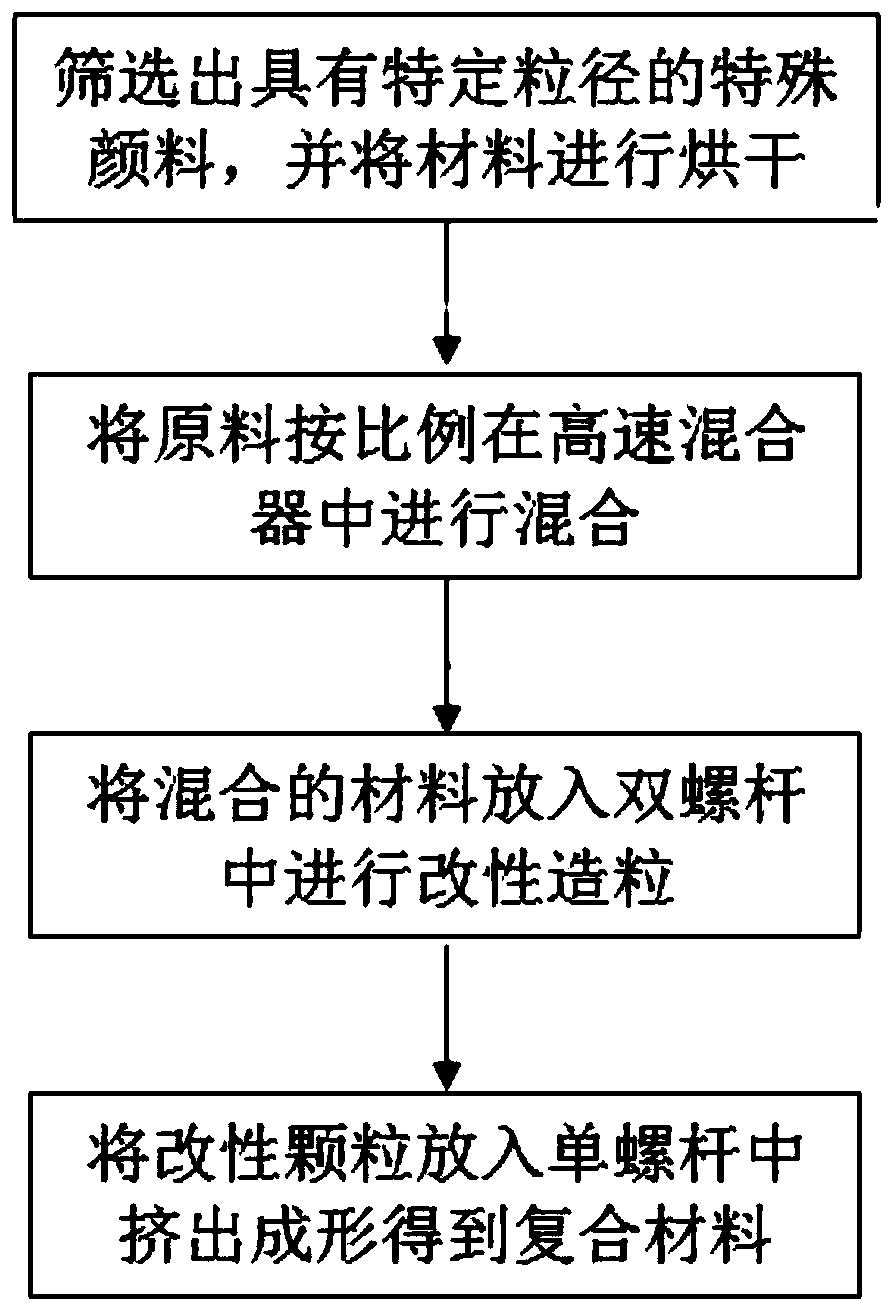

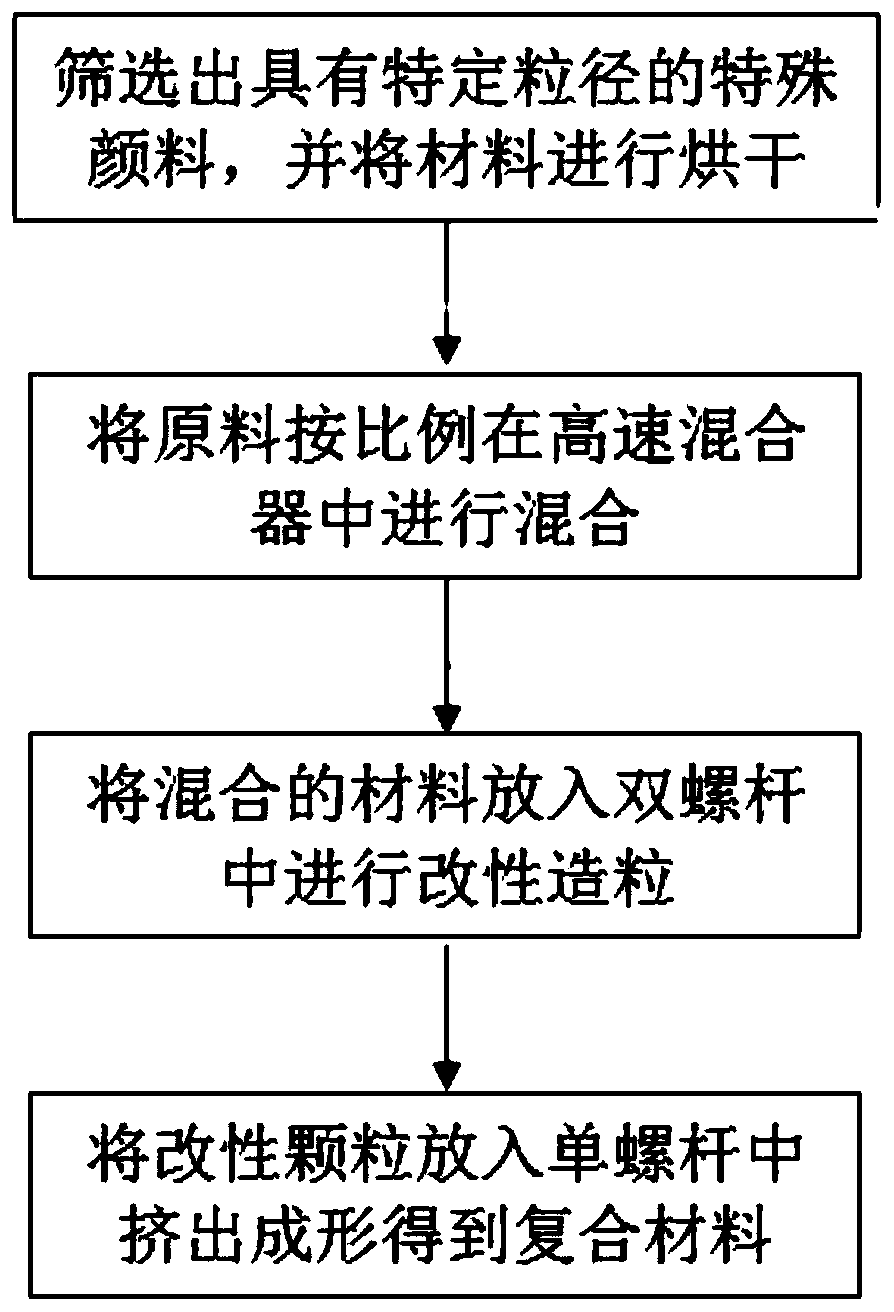

Method used

Image

Examples

Embodiment 1

[0035] (1) Use 100-mesh and 400-mesh sieves to sieve the gold powder and dry it at a temperature of 60°C to 70°C.

[0036] (2) The content of each monomer of acrylonitrile-butadiene-styrene is 25% of acrylonitrile, 10% of butadiene, and 65% of styrene. The obtained ABS material is dried at a temperature of 45 ℃~55℃.

[0037] (3) Add the following weight ratio raw materials into a high-speed mixer and mix for 2 hours.

[0038] Acrylonitrile-butadiene-styrene raw material: 80 parts

[0039] Gold dust: 3 servings

[0040] Silane coupling agent: 1 part

[0041] ST-4: 2 parts

[0042] EBS: 1 copy

[0043] Antioxidant 168: 0.2 parts

[0044] (4) Put the mixed material into the twin-screw for modification and granulation.

[0045] (5) Put the modified particles into a single screw and extrude to obtain a golden ABS composite material. After processing and printing by FDM forming method, a golden ABS part is obtained.

Embodiment 2

[0047] (1) Use 100-mesh and 400-mesh sieves to screen the silver powder, and carry out drying treatment. The drying temperature is 60°C to 70°C.

[0048] (2) The content of each monomer of acrylonitrile-butadiene-styrene is 22% of acrylonitrile, 15% of butadiene, and 63% of styrene, and the obtained ABS material is dried, and the drying temperature is 45 ℃~55℃.

[0049] (3) Add the following weight ratio raw materials into a high-speed mixer and mix for 2.5 hours.

[0050] Acrylonitrile-butadiene-styrene raw material: 85 parts

[0051] Silver powder: 10 parts

[0052] Silane coupling agent: 0.4 parts

[0053] ST-8: 3 servings

[0054] EBS: 0.8 shares

[0055] Antioxidant 618: 0.5 parts

[0056] (4) Put the mixed material into the twin-screw for modification and granulation.

[0057] (5) Put the modified particles into a single-screw and extrude to obtain a silver-colored ABS composite material. After processing and printing by FDM forming method, a silver ABS part is o...

Embodiment 3

[0059] (1) Use 100-mesh and 400-mesh sieves to sieve wood flour, and then dry it at a temperature of 45°C to 55°C.

[0060] (2) The content of each monomer of acrylonitrile-butadiene-styrene is 20% of acrylonitrile, 20% of butadiene, and 60% of styrene, and the obtained ABS material is dried, and the drying temperature is 45 ℃~55℃.

[0061] (3) Add the following weight ratio raw materials into a high-speed mixer and mix for 3 hours.

[0062] Acrylonitrile-butadiene-styrene raw material: 90 parts

[0063] Wood flour: 2 parts

[0064] Titanate coupling agent: 1 part

[0065] ST-9: 10 parts

[0066] EBS: 1 copy

[0067] Antioxidant 618: 0.3 parts

[0068] (4) Put the mixed material into the twin-screw for modification and granulation.

[0069] (5) Put the modified particles into a single screw and extrude to obtain a wood-colored ABS composite material. After processing and printing by FDM forming method, ABS parts with wood color are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com