Ultraviolet curable adhesive film

A technology of curing glue and ultraviolet light, which is applied in the direction of film/sheet adhesives, adhesives, epoxy resin glue, etc., can solve the problems of slow curing speed and the influence of semiconductor stress, and achieve high bonding strength and easy to obtain The effect of suitable preparation and surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The ultraviolet curable adhesive film of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereby.

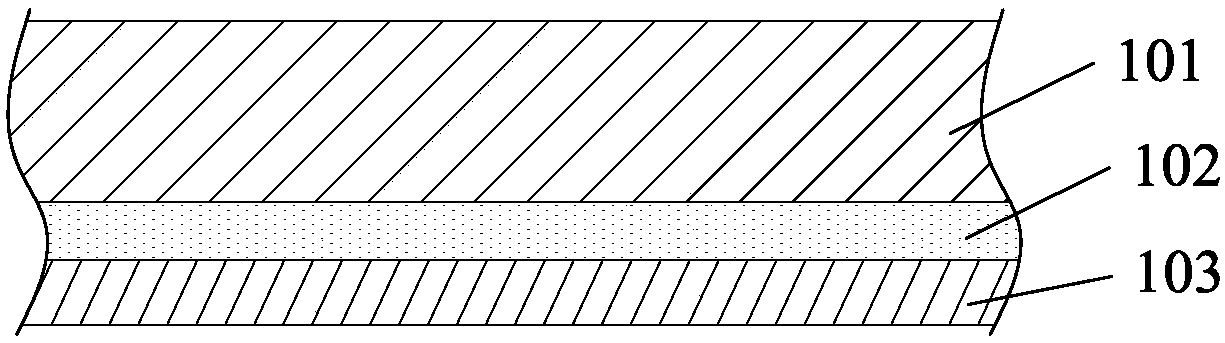

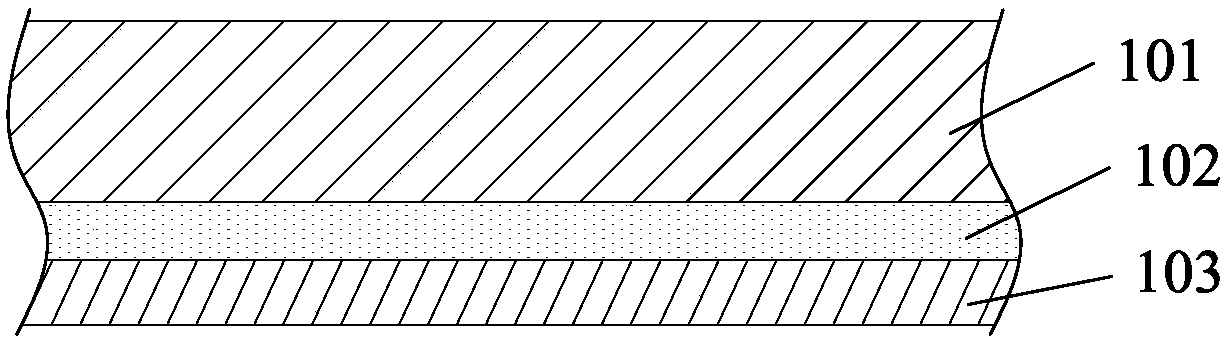

[0014] Such as figure 1 As shown, the UV-curable adhesive film of the present invention includes a base film 101 , a UV-curable adhesive 102 formed on the base film 101 and a removable film 103 formed on the UV-curable adhesive 102 . Specifically, the thickness of the base film 101 is 160-190 μm, the thickness of the ultraviolet curable adhesive 102 is 2-5 μm, and the thickness of the removable film 103 is 30-50 μm. After the removable film 103 is removed, the UV-curable adhesive 102 and the base film 101 can be cured on the semiconductor by irradiating ultraviolet light.

[0015] Specifically, the components of the UV-curable adhesive are as follows: epoxy resin A 12-15%; epoxy acrylate 10-15%; epoxy resin B 21-35%; diluent 15-25%; free radical initiator 3-8%; cationic initiator 3-8%. Nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com