Packaging bag with high resistance to environmental stress cracking

A technology of environmental stress cracking and packaging bags, which is applied in the field of packaging bags, can solve problems such as insufficient strength, increased transportation costs, and potential environmental safety hazards, and achieve the effects of improving flexibility and reducing residual loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

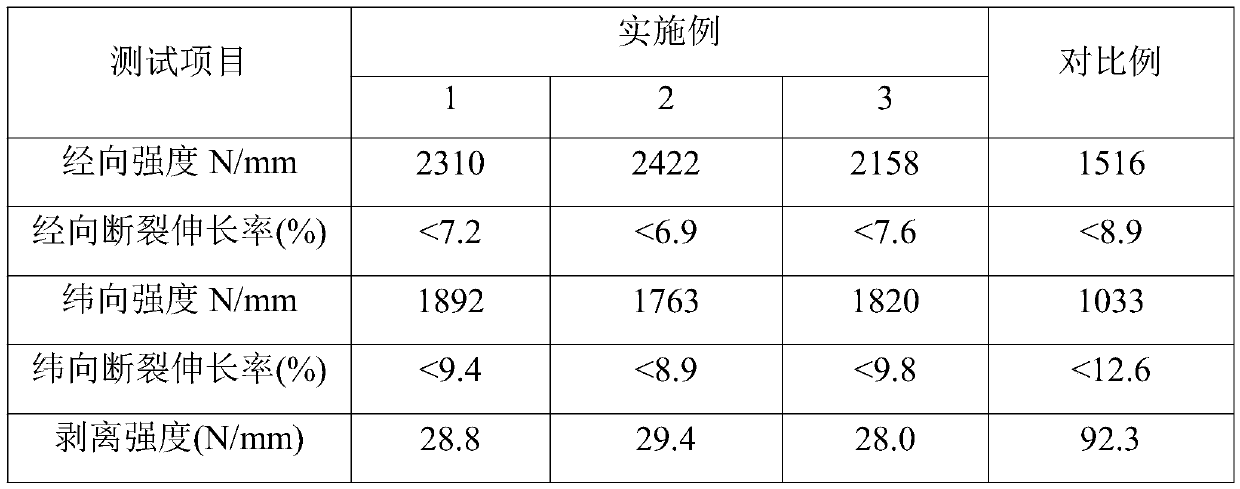

Examples

Embodiment 1

[0017] A packaging bag with high resistance to environmental stress cracking, including a fabric body, the fabric body sequentially includes a non-stick coating, a waterproof coating and an outer layer of woven cloth from the inside to the outside, and the waterproof coating is perfluorinated The composition of alkyl silane resin and PU resin, the mass ratio of described perfluoroalkyl silane resin and PU resin is 2:1; Described release coating is the mixture composition of PP and PE, and described PP and PE The mass ratio is 0.5:1;

[0018] The outer layer of the woven cloth includes by weight: 65 parts of isotactic polypropylene, 13 parts of atactic polypropylene, 9 parts of high-density polyethylene, 8 parts of polyolefin elastomer and 5 parts of performance reinforcing agent;

[0019] The performance enhancing agent comprises by weight: 26 parts of mica powder, 58 parts of superfine talcum powder and 16 parts of superfine calcium carbonate.

[0020] In the above technical...

Embodiment 2

[0027] A packaging bag with high resistance to environmental stress cracking, including a fabric body, the fabric body sequentially includes a non-stick coating, a waterproof coating and an outer layer of woven cloth from the inside to the outside, and the waterproof coating is perfluorinated The composition of alkyl silane resin and PU resin, the mass ratio of described perfluoroalkyl silane resin and PU resin is 2.5:1; Described release coating is the mixture composition of PP and PE, and described PP and PE The mass ratio is 1:1;

[0028] The outer layer of the woven cloth includes by weight: 71 parts of isotactic polypropylene, 11 parts of atactic polypropylene, 8 parts of high-density polyethylene, 6 parts of polyolefin elastomer and 4 parts of performance reinforcing agent;

[0029] The performance enhancing agent comprises by weight: 22 parts of mica powder, 60 parts of superfine talcum powder and 18 parts of superfine calcium carbonate.

[0030] In the above technical...

Embodiment 3

[0037] A packaging bag with high resistance to environmental stress cracking, including a fabric body, the fabric body sequentially includes a non-stick coating, a waterproof coating and an outer layer of woven cloth from the inside to the outside, and the waterproof coating is perfluorinated The composition of alkyl silane resin and PU resin, the mass ratio of described perfluoroalkyl silane resin and PU resin is 2.5:1; Described release coating is the mixture composition of PP and PE, and described PP and PE The mass ratio is 0.5:1;

[0038] The outer layer of the woven cloth includes by weight: 63 parts of isotactic polypropylene, 13 parts of atactic polypropylene, 12 parts of high-density polyethylene, 8 parts of polyolefin elastomer and 4 parts of performance reinforcing agent;

[0039] The performance enhancing agent comprises by weight: 28 parts of mica powder, 55 parts of superfine talcum powder and 17 parts of superfine calcium carbonate.

[0040] In the above techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com