Multi-purpose intelligent adjustment testing production device with airflow drying and static electricity detecting and eliminating functions

A technology of airflow drying and intelligent adjustment, applied in the direction of measuring device, drying gas arrangement, drying solid materials, etc., can solve the problem of difficult to achieve ionized air entry and uniform mixing, reduce the outflow of hot air, eliminate influence, and reduce excitation vibration. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

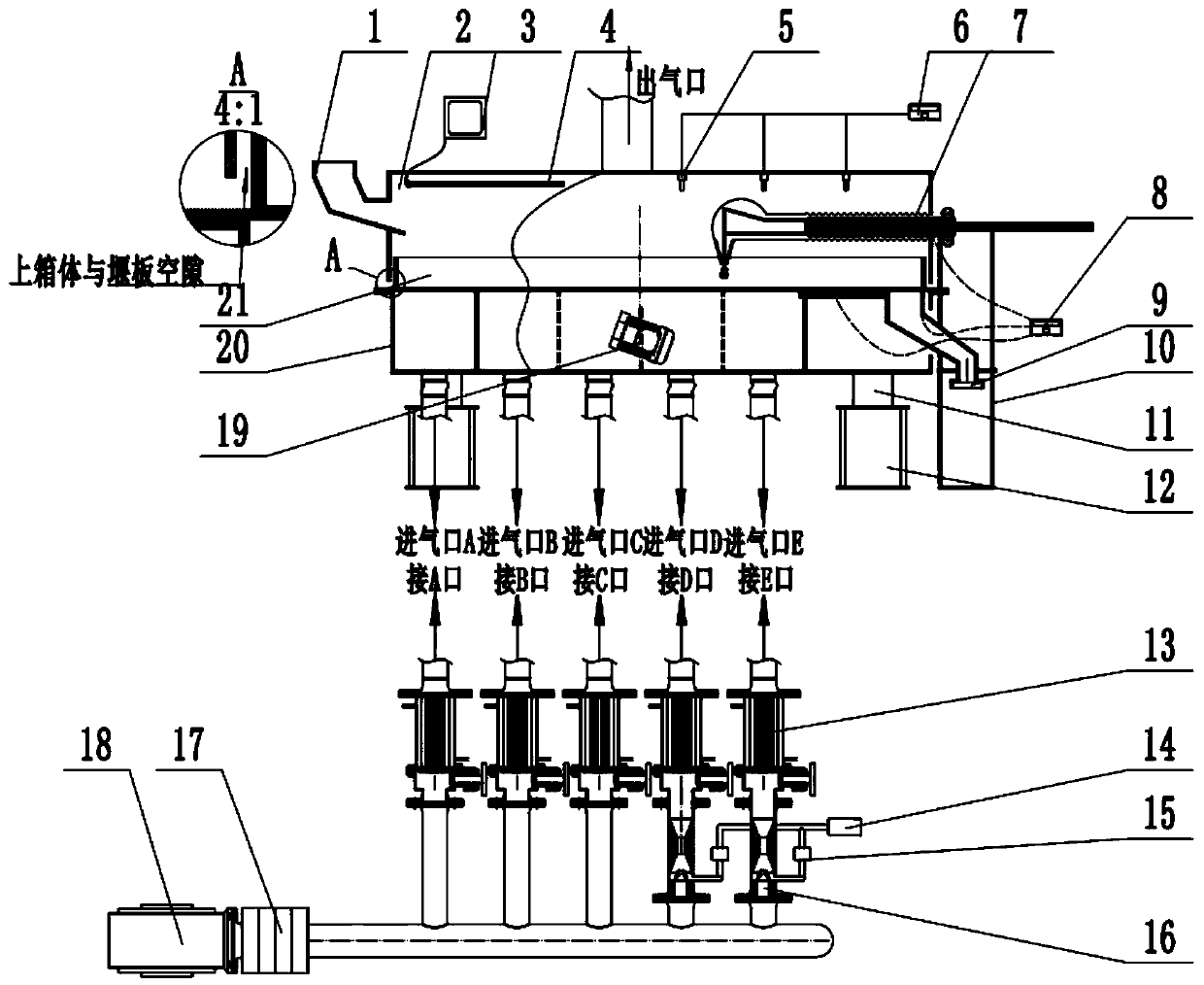

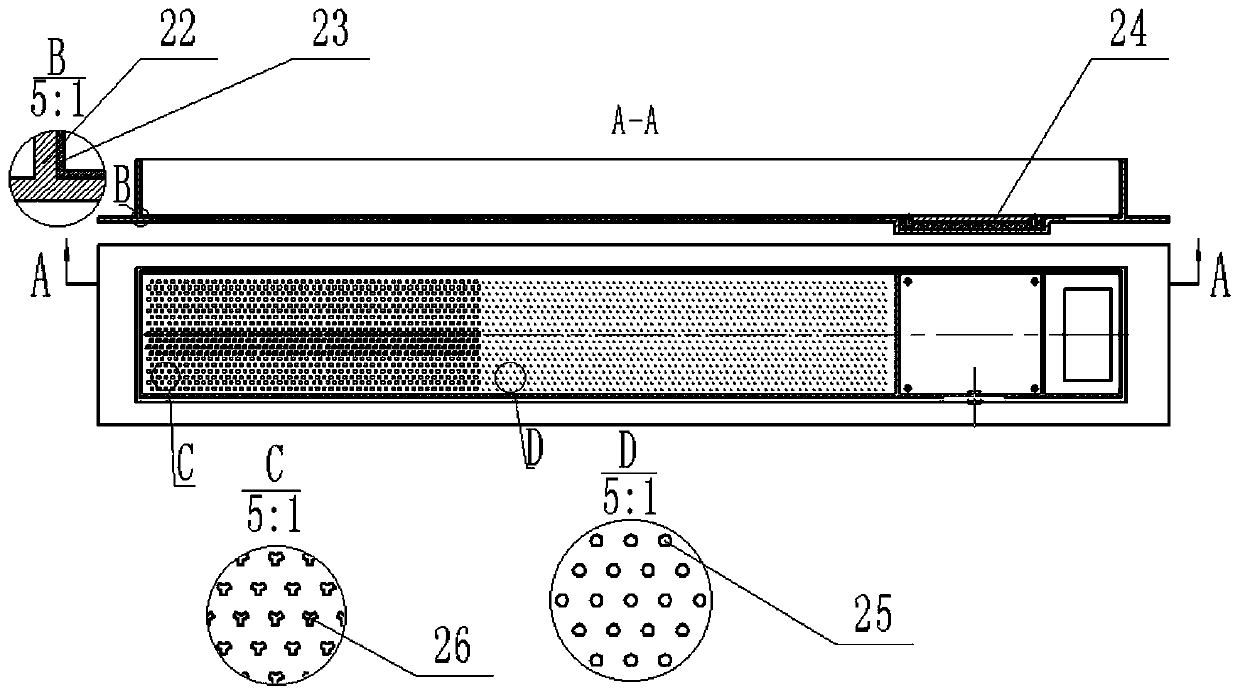

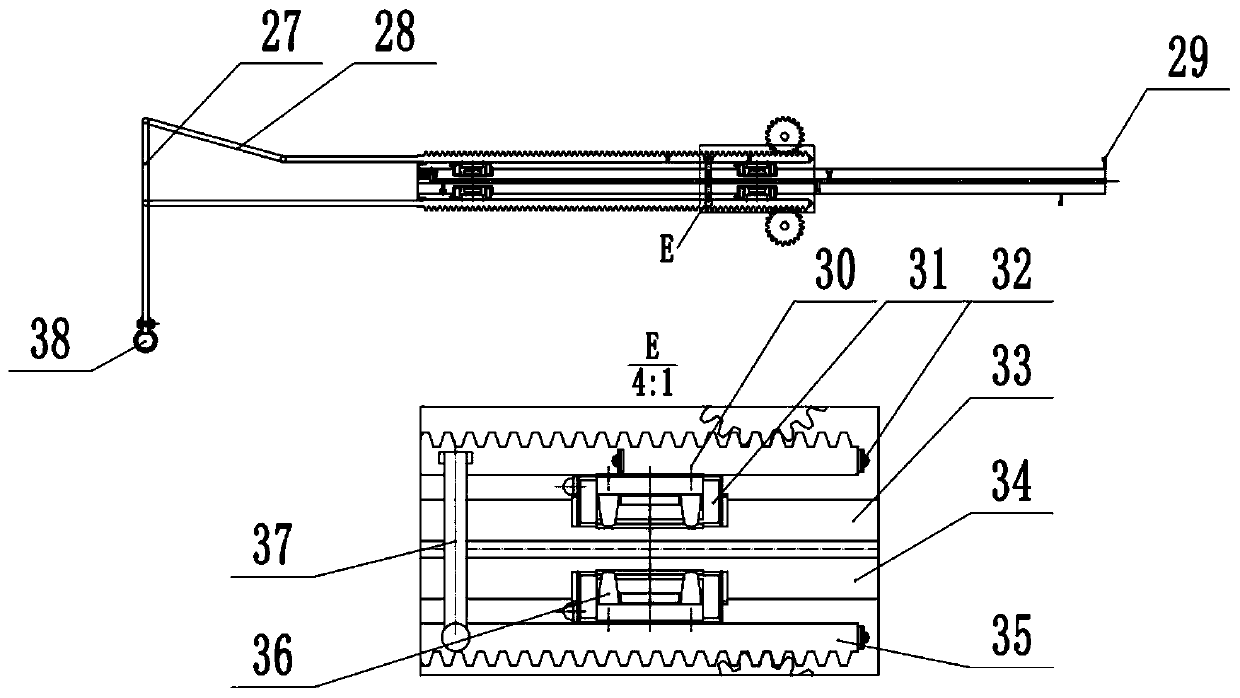

[0032] In Embodiment 2, static electricity monitoring, discharge test and static elimination can be carried out on water-containing materials. After the wet material enters from the feeding port (1), the potential becomes higher due to the action of the static electricity generating rod (4), and at the same time, it becomes high-potential charged particles under its own vibration, collision and friction. The potential of the charged particles can be measured by an electrostatic potential sensor (5) fixed above the vibrating fluidized bed. Corona discharge is induced by changing the position of the adjustable spherical electrostatic needle (35), brush discharge can be induced when moving to the static discharge plate (24), and the electrostatic discharge outlet (9) induces corona discharge and brush discharge. The discharge capacity of the three mechanisms can be measured by the connected electricity meter.

Embodiment 3

[0033] In Example 3, the static electricity generated during the drying process of the water-containing material can be eliminated. After the wet material enters from the feed port, the wet material can enter from the feed port (1), and the electric potential can be increased by the static generating rod (4), and at the same time, it becomes high-potential charged particles due to its own vibration, collision and friction. The position of the charged particles can be measured by an electrostatic potential sensor (5) fixed above the vibrating fluidized bed. When the charged particles reach the dangerous potential of discharge, the two intake manifolds of the vibrating fluidized bed near the end of the discharge port suck the ion wind generated by the ion gun (15) through the Venturi device (16) to neutralize the high potential charge Particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com