Micro-scale collaborative surface structure for enhancing boiling heat transfer

A technology for strengthening the boiling and heat exchange structure, which is applied in the field of strengthening heat transfer to achieve the effect of promoting separation and enhancing the effect of boiling heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

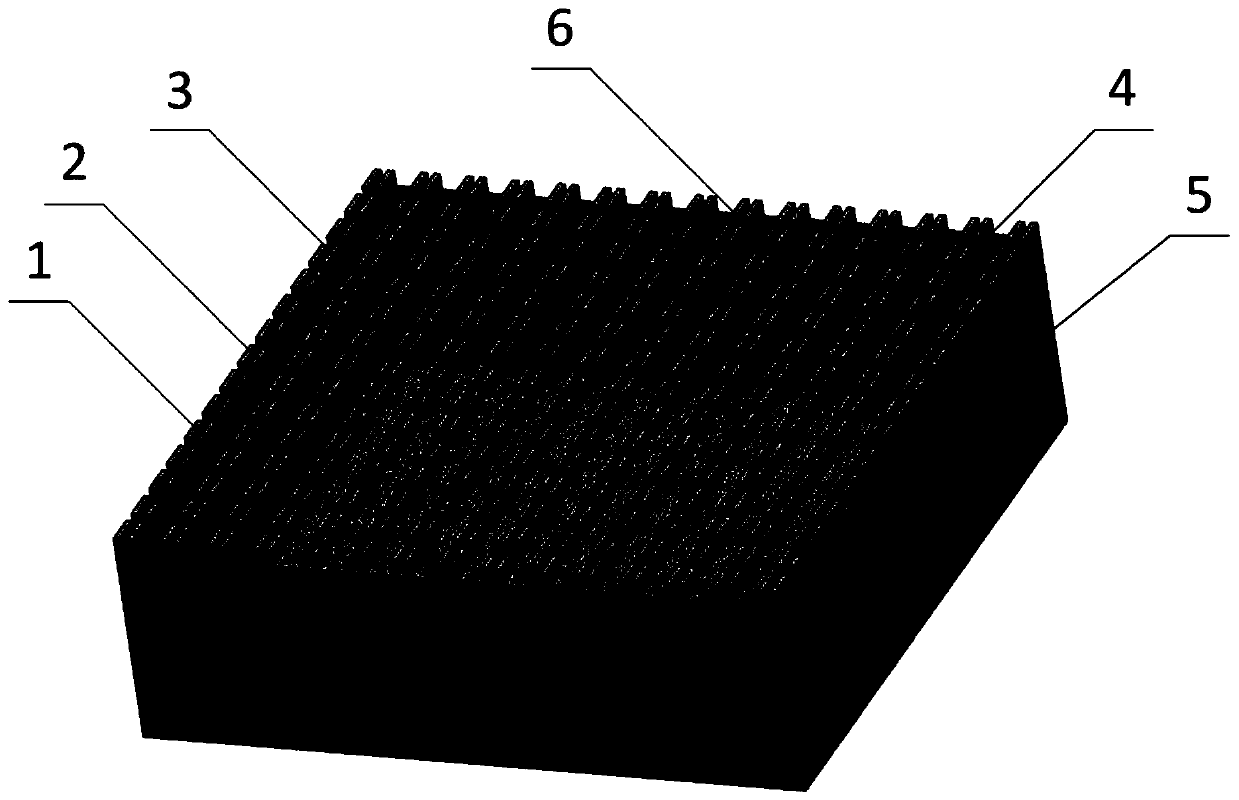

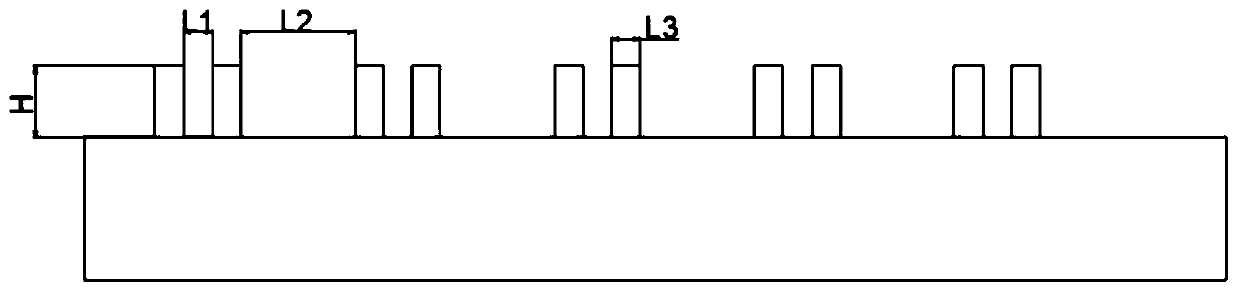

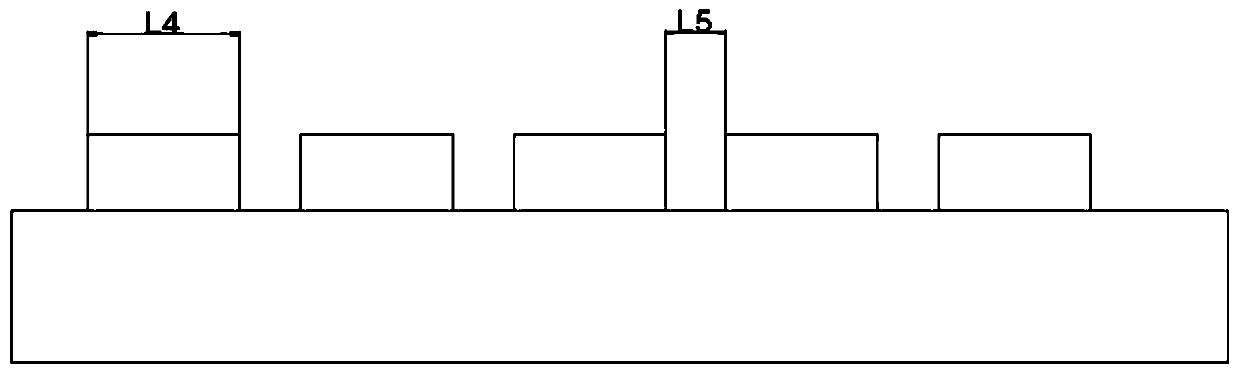

[0014] Such as Figure 1~3 As shown, a micro-scale cooperative structure of surface enhanced boiling heat transfer, including large groove 1, small groove 2, connecting groove 3, micro-rib 4, base surface 5 and superhydrophobic coating 6; described enhanced boiling structure The surface of the base surface 5 is formed by mechanical cutting, structural electroplating or laser ablation to form a synergistic scale surface; the surface of the base surface 5 is divided by micro-ribs 4 to form large grooves 1, small grooves 2 and connecting grooves 3;

[0015] The large grooves 1 and the small grooves 2 are arranged in a staggered manner, and the large grooves 1 and the small grooves 2 are formed by a plurality of evenly spaced micro-ribs, and the width L3 of the micro-ribs is 50-100 μm; the grooves of the small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com