An automatic detection device for the appearance of a brazing grid

An automatic detection and grid technology, which is applied in the direction of measuring devices, optical testing defects/defects, program control manipulators, etc., can solve the problems of low detection efficiency, heavy detection workload, low detection efficiency, etc., to increase the rotation angle and Working range, realize multi-directional detection, realize the effect of free transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

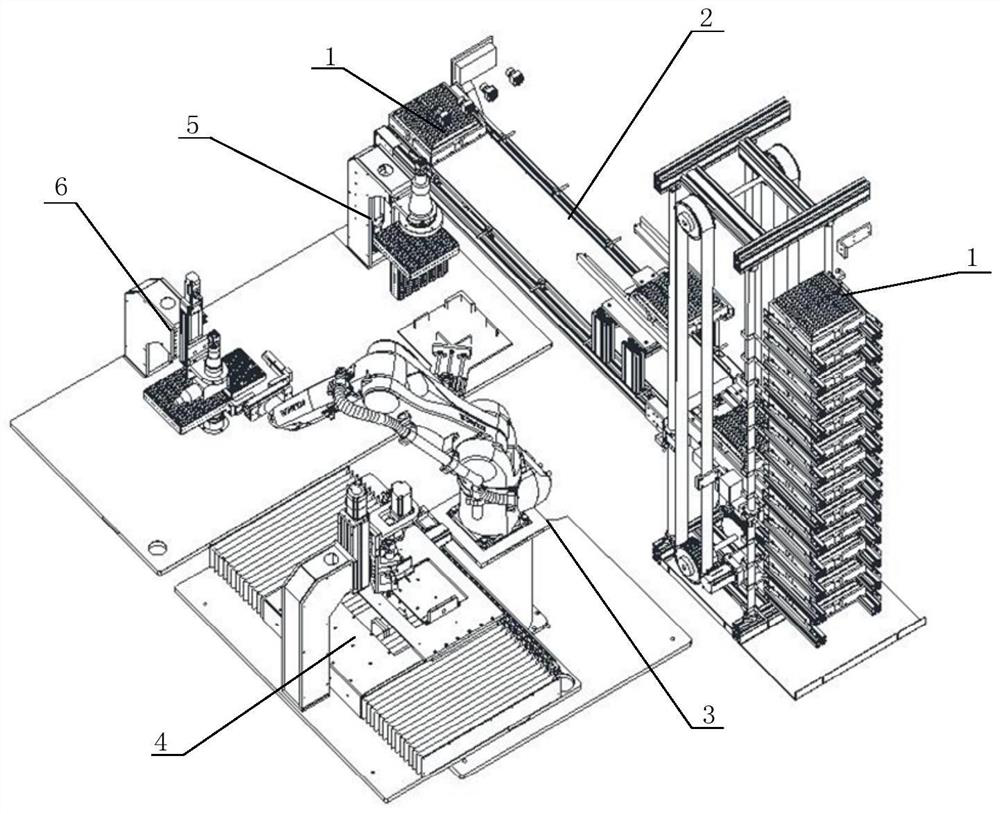

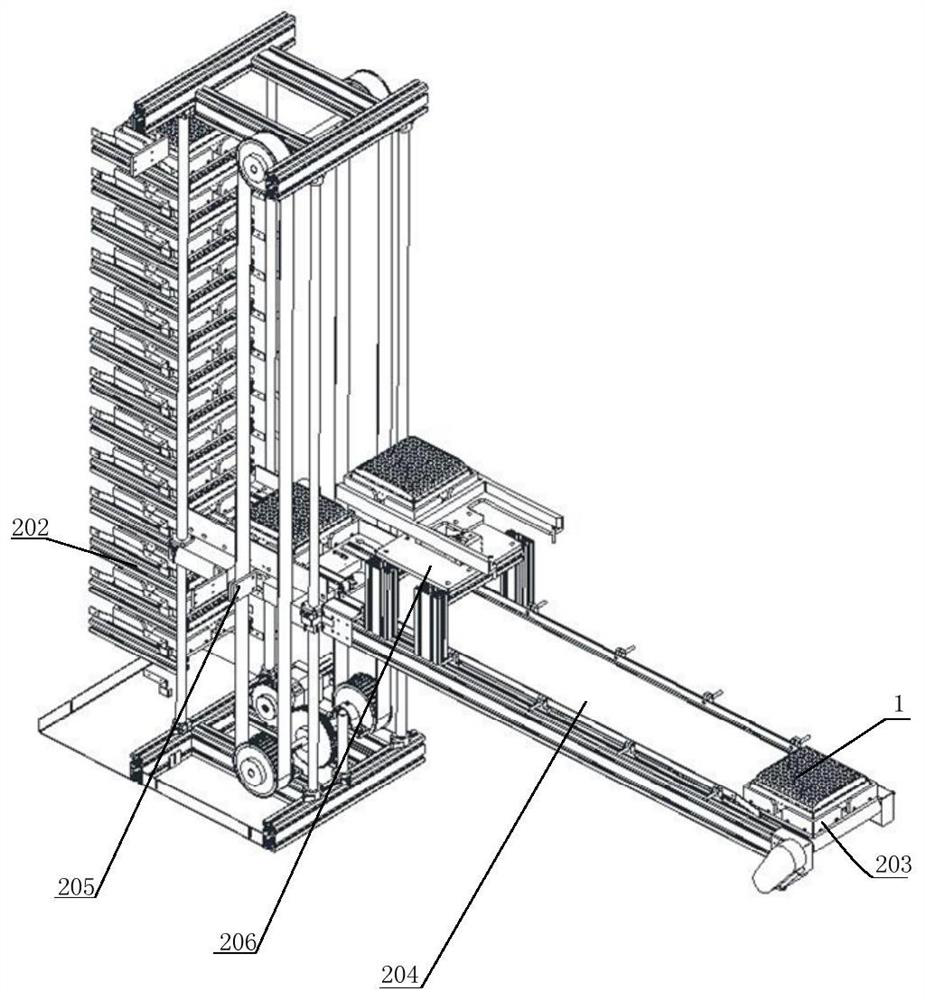

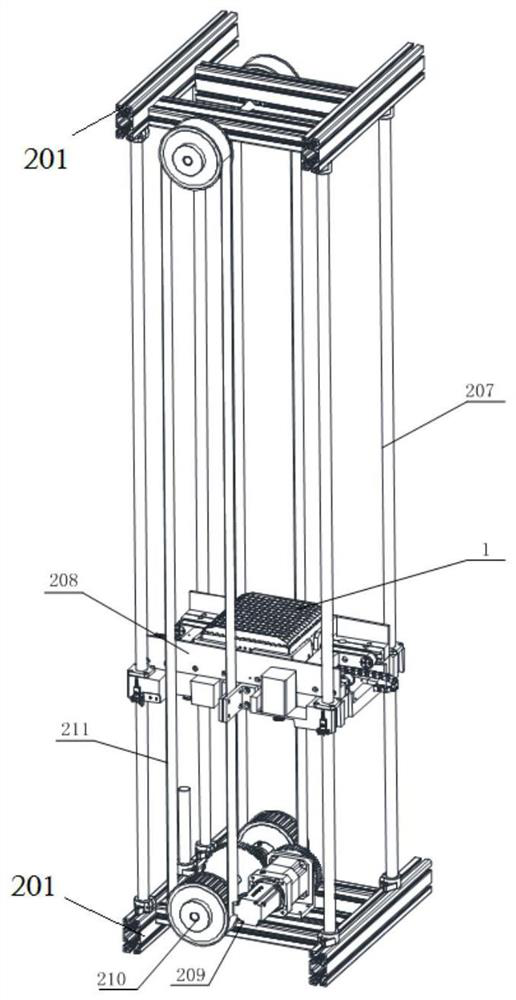

[0048] Such as figure 1 As shown, the detection device includes an automatic feeding device 2, a mechanical clamping arm 3 installed next to the automatic feeding device 2 for clamping the grid 1 to be detected, and a positioner installed at the output end of the automatic feeding device 2 in turn. Mechanism 5 and blockage detection mechanism 6, and weld seam detection mechanism 4 below the mechanical clamping arm 3.

[0049] The automatic feeding mechanism 2 is used for automatic access to the grid and for detection and access;

[0050] The mechanical clamping arm 3 is used to clamp the grid stored in the automatic feeding mechanism and can freely change the orientation and angle of the clamped grid;

[0051] The positioning mechanism 5 is used to identify the surface with lettering on the grid clamped by the mechanical clamping arm from the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com