RF MEMS switch based on superlubricity structure

A technology of switch structure and sliding part, applied in the field of RFMEMS switch based on super-slip structure and its realization, can solve the problems of increasing the mechanical strength of the device, reducing the response speed of the device, failure, etc., so as to achieve no friction loss, stable device performance, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiment 1 of the present invention will be further described below in conjunction with accompanying drawing:

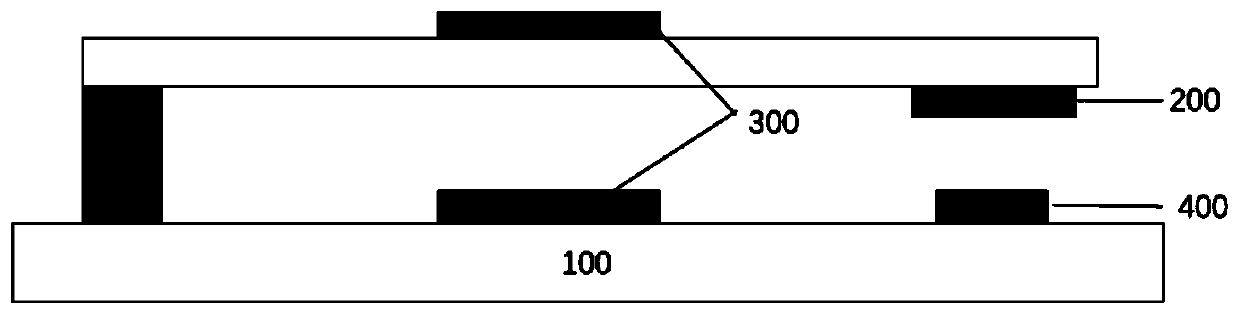

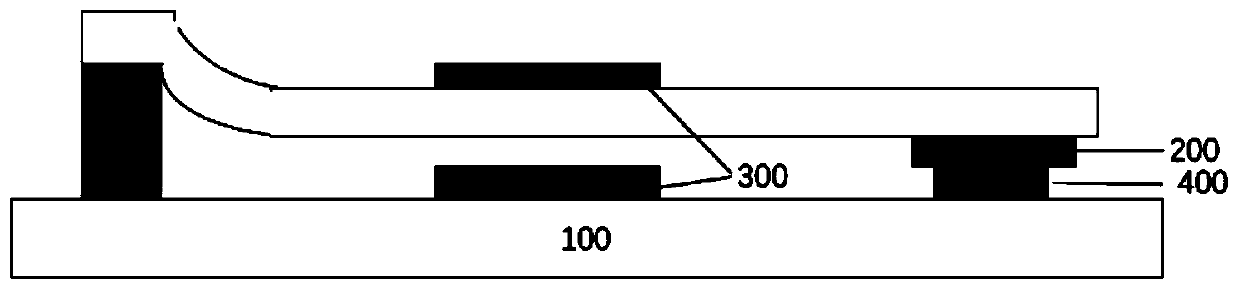

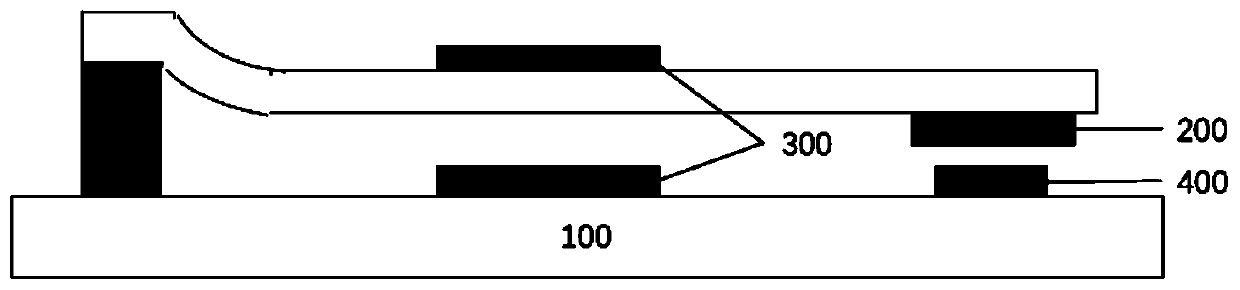

[0037] See attached Figure 3(a) , 3(b) , the present invention provides a kind of RF MEMS switch, and this RF MEMS switch comprises substrate 1, the fixed part that horizontally arranges on described substrate 1, movable part and drive part; Wherein described fixed part comprises fixed part contact electrode 9; wherein the driving part comprises a driving electrode 10; wherein the movable part comprises a self-supporting part 2 and a slidable part 3 composed of self-recoverable graphite islands; a metal cover 4 is formed on the slidable part 3, The metal cover 4 is an optional structure and can also be omitted; a driven electrode 6 and a movable part contact electrode 8 are formed on the metal cover 4; 8 is formed with a second insulating layer 7, in this embodiment 1, the driven electrode 6 is located above the movable part contact electrode 8, but in fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com