Synergistic toughening of epoxy modified by graphene and block copolymer

A technology of graphene oxide and copolymer, which is applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., and can solve problems such as limiting the processability of preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Materials. The chemical structures of the epoxy resin components and block copolymer modifiers used in this study are shown in Scheme 1. The epoxy monomer was diglycidyl ether of bisphenol A (D.E.R. 332) supplied by the Dow Chemical Company. The hardener is a mixture of two components: the trifunctional crosslinker 1,1,1-tris(4-hydroxyphenyl)ethane (THPE, Aldrich) and the difunctional chain extender bisphenol A (Parabis, Dow Chemical ). Both components react with epoxy monomers; the ratio of crosslinker to chain extender in the formulation is varied to systematically vary the crosslink density of the resulting network. Ethyltriphenylphosphonium acetate (70% in methanol, Alfa Aesar) was used as catalyst to reduce cure time and provide better control over network branching, resulting in a more uniform epoxy network.

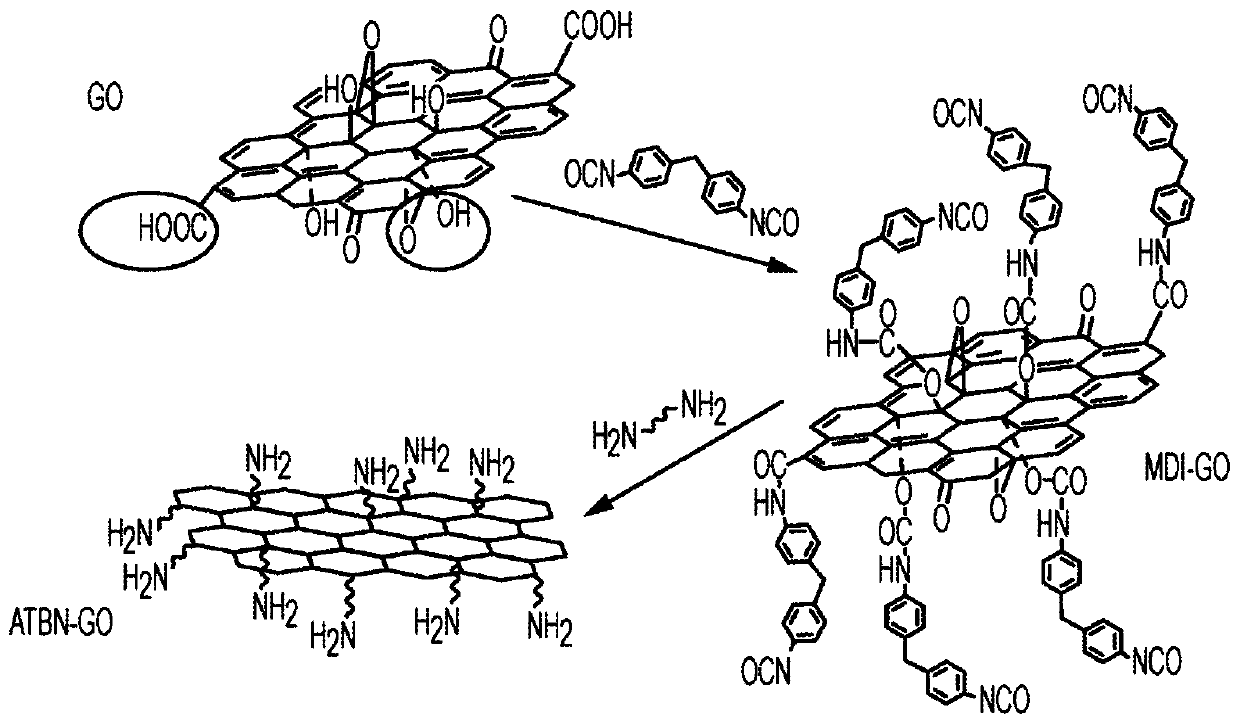

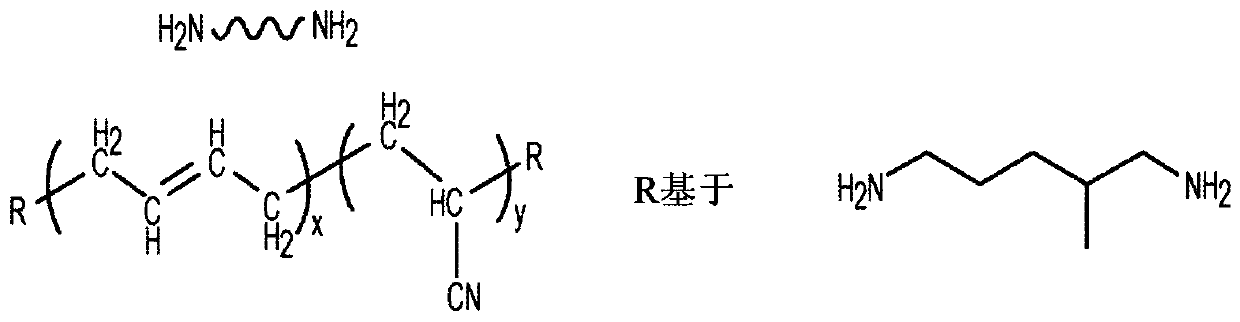

[0072] The epoxy was modified with two additives. The first is the typical poly(ethylene oxide)-b-poly(ethylene-alternating-propylene) (PEO-b-PEP) dibloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com