High speed blender with hydrogen supplement function

A wall-breaking machine and functional technology, applied in the field of wall-breaking machines, can solve the problems of nutrient loss, nutrient liquid food, etc., and achieve the effect of improving utilization efficiency and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

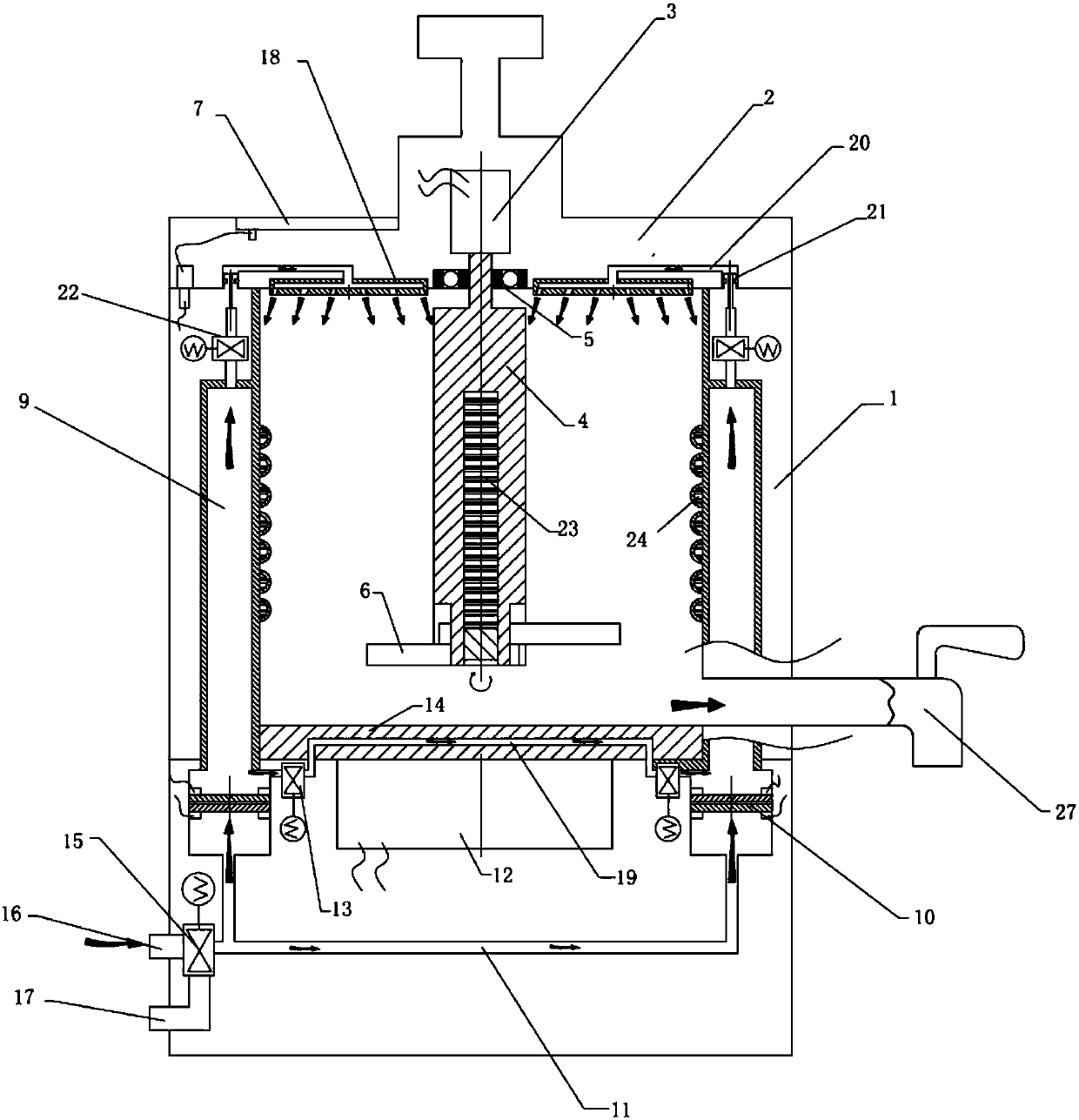

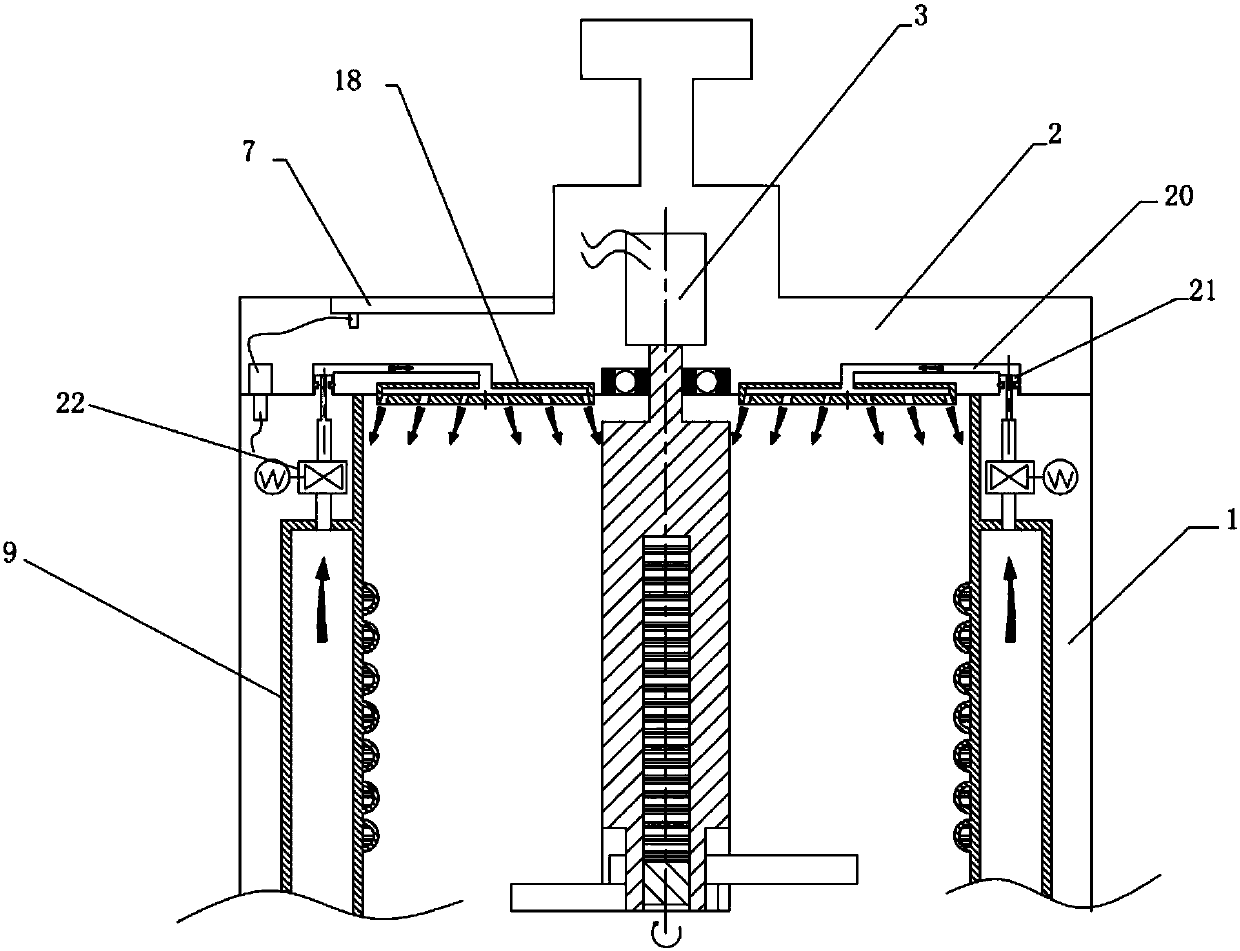

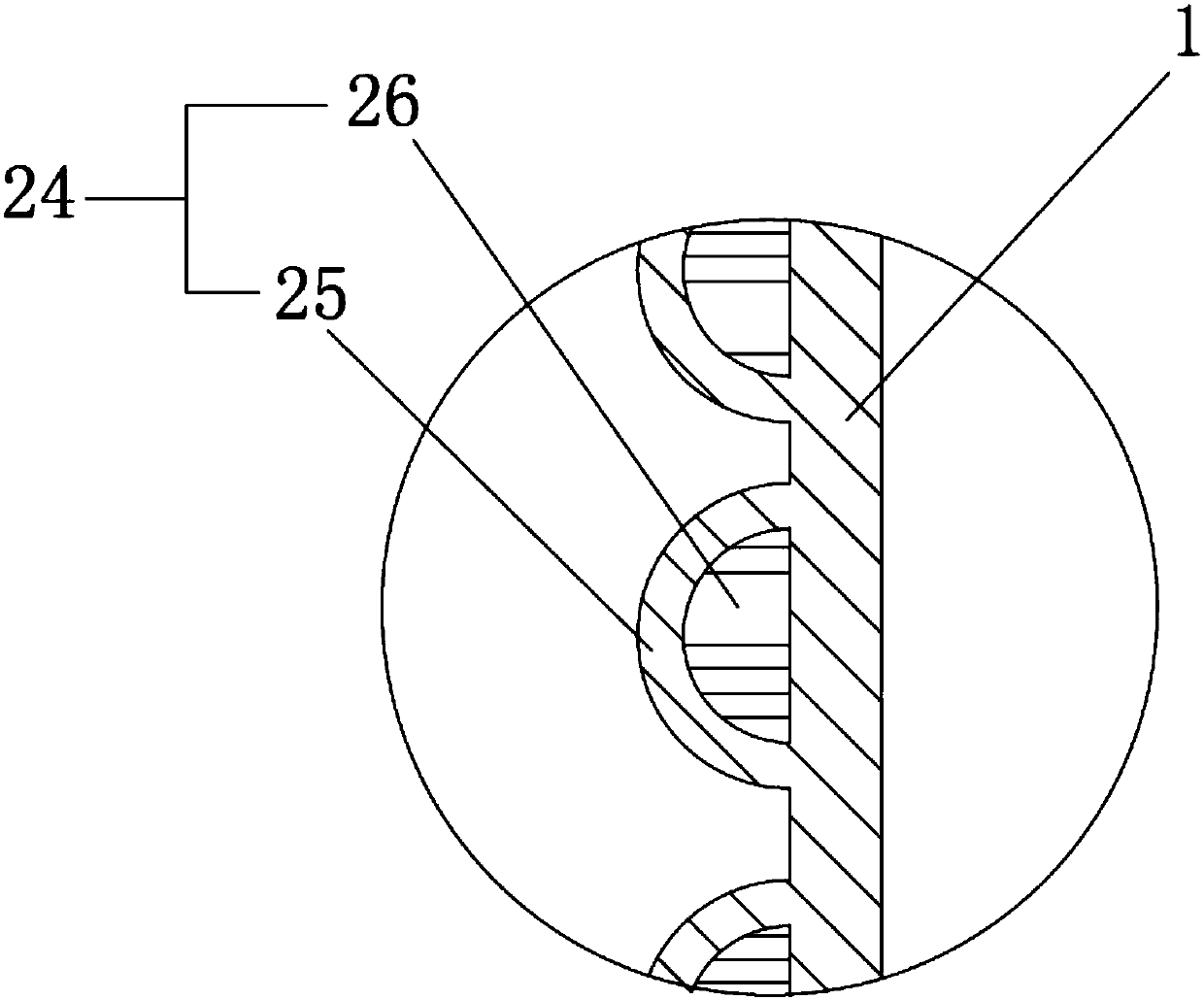

[0029] As shown in the figure, a wall breaker with hydrogen replenishment function includes a body 1, an upper cover 2, a motor 3, a rotating shaft 4, a bearing 5, a blade 6 and a control panel 7, and the control panel 7 is installed on the upper cover 2 Above, the fuselage of the motor 3 and the bearing 5 are installed in the upper cover 2, and the heating shaft of the motor 3 passes through the bearing 5 to link with the shaft 4, and the shaft 4 is arranged in the inner cavity 8 of the body 1. A blade 6 is installed on the rotating shaft 4, an electrolysis chamber 9 is provided on the side wall of the body 1, and an electrolysis module 10 is provided in the electrolysis chamber 9, and also includes a liquid inlet pipe 11, an induction cooker heating element 12, and a solenoid valve 13 , heat conduction metal plate 14, electromagnetic valve tee 15, water inlet 16, water outlet 17 and spray outlet 18, described water inlet 16 and water outlet 17 are communicated with electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com