Ball-heading blank-making machine of shackle and using method thereof

The technology of blank making machine and frame is applied in the field of blank making of pier balls for shackles, which can solve the problems of high labor intensity of workers, irregular blank deformation, affecting the yield of finished products, etc., so as to save raw materials, fast deformation process, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples show and describe the basic principles and main structural features of the present invention. Under the premise of not departing from the spirit and scope of the present invention, the present invention also has various changes and improvements. , these changes and improvements all fall within the scope of the claimed invention.

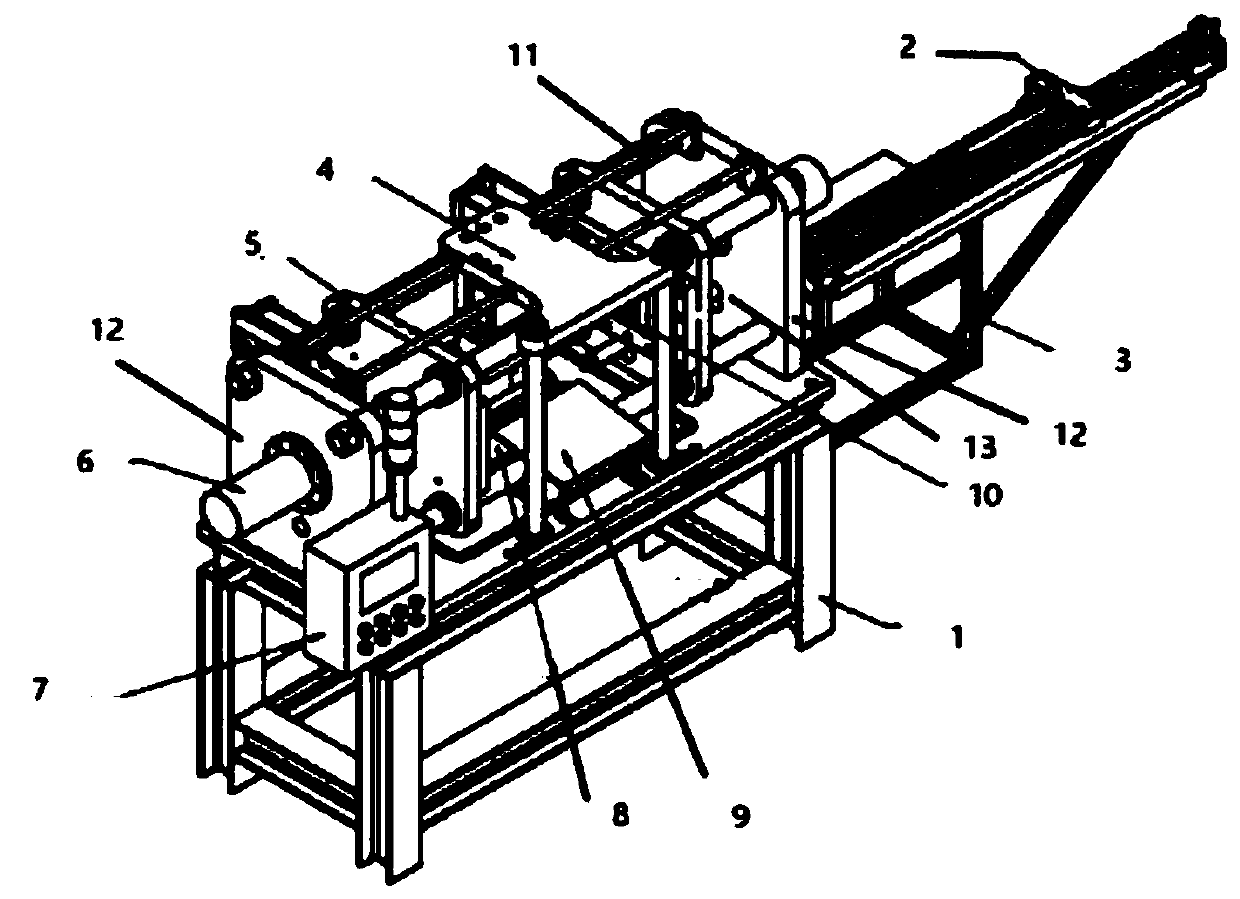

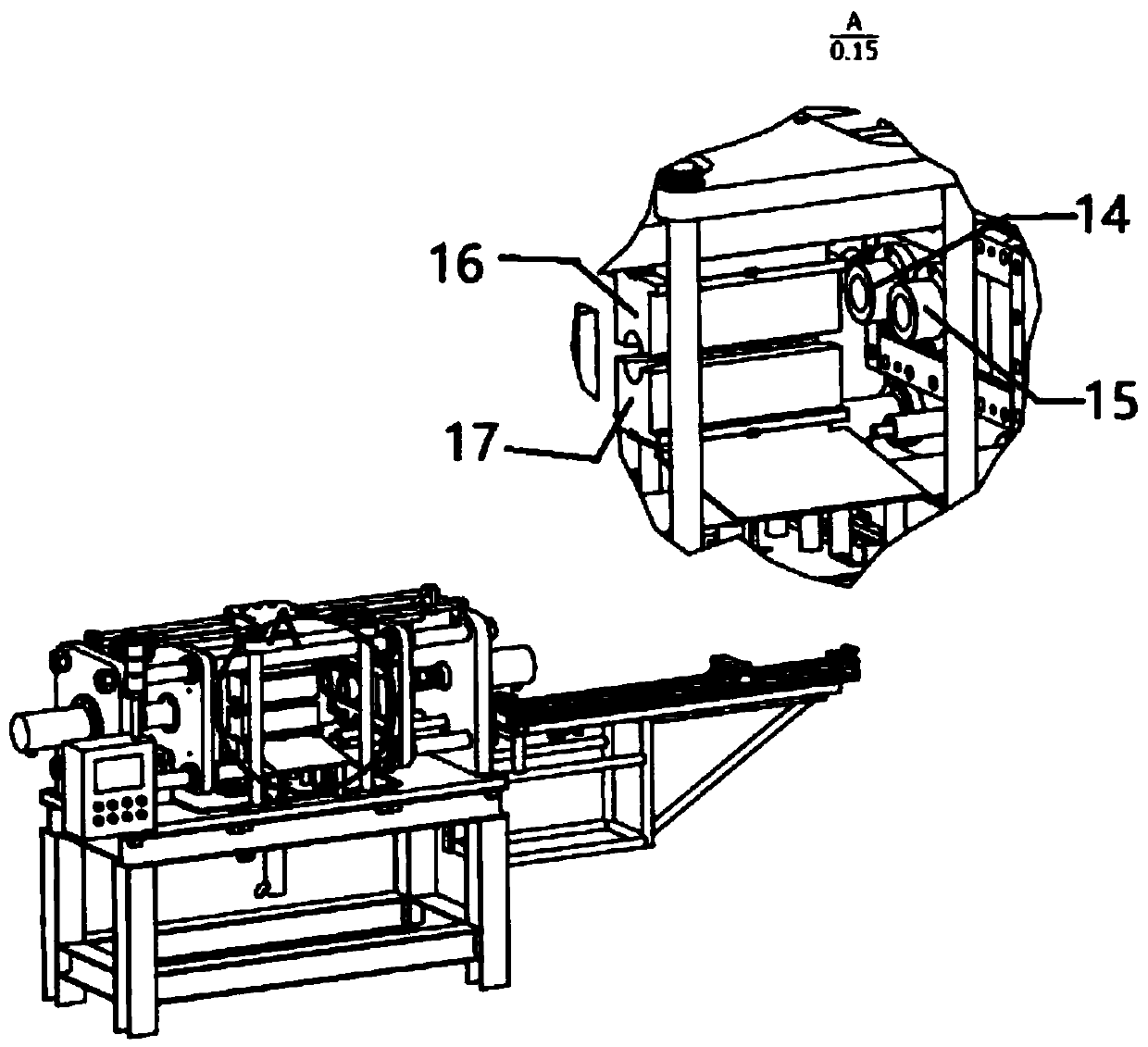

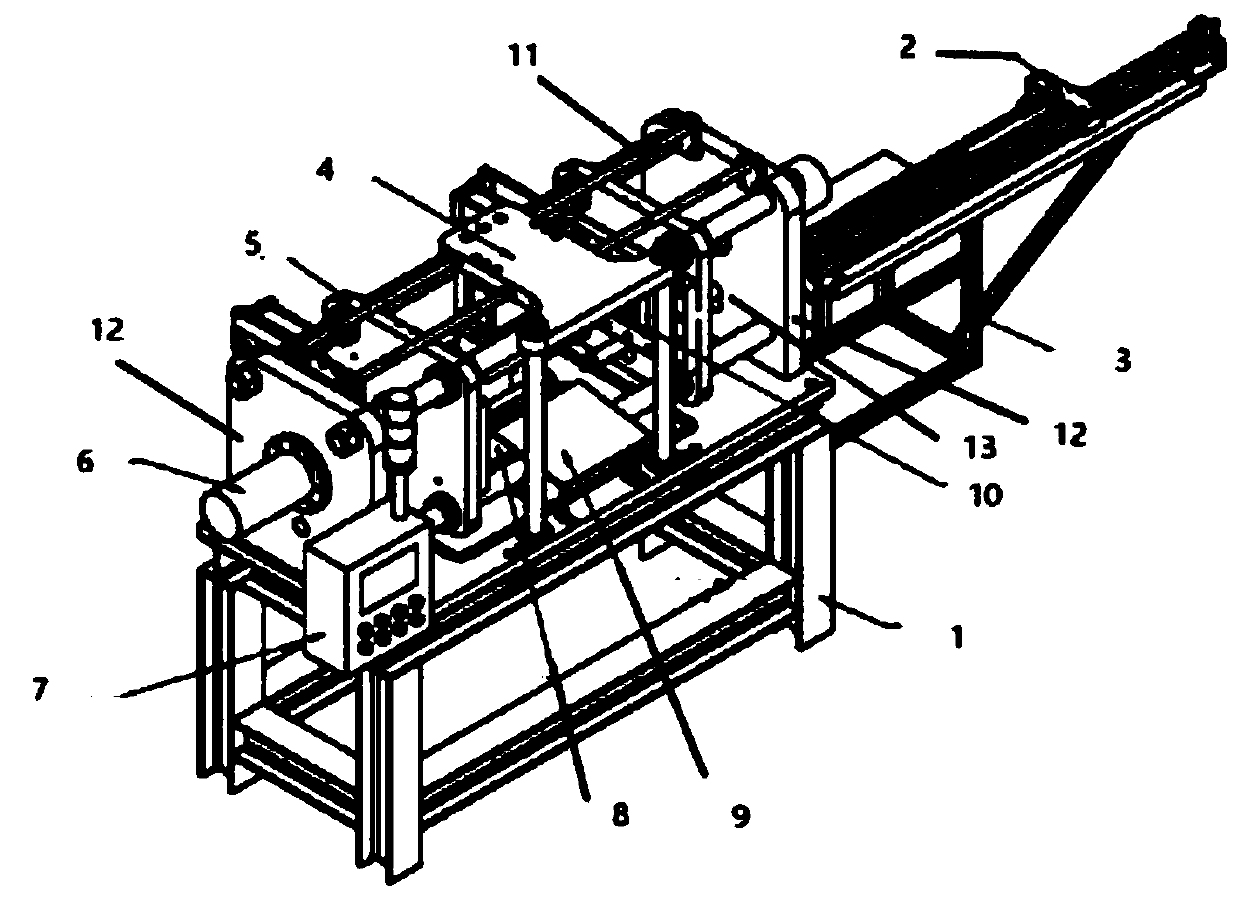

[0027] A shackle pier ball blank making machine, comprising a frame main body 1, an automatic feeding mechanism 3, a mold fixing mechanism 4, a forming mold group 5, a lifting mechanism 8, an automatic discharging mechanism and a control panel 7, the forming mold group 5 Including a primary forming die 14 and a secondary forming die 15 , the forming die set 5 is installed on the die fixing mechanism 4 . The automatic feeding mechanism 3 is located on one side of the frame main body 1, including the ejector rod 2 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com