A kind of heat dissipation tooling and application of patch ceramic disk used in LED chip substrate thinning process

A technology of LED chips and heat dissipation tooling, which is applied in the direction of manufacturing tools, grinding devices, metal processing equipment, etc., can solve the problems of affecting the recycling efficiency of ceramic disks, the smoothness of thinning operations, and the reduction of cooling effect, so as to prevent ceramic disks from slipping , solve the effect of rapid cooling and avoid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

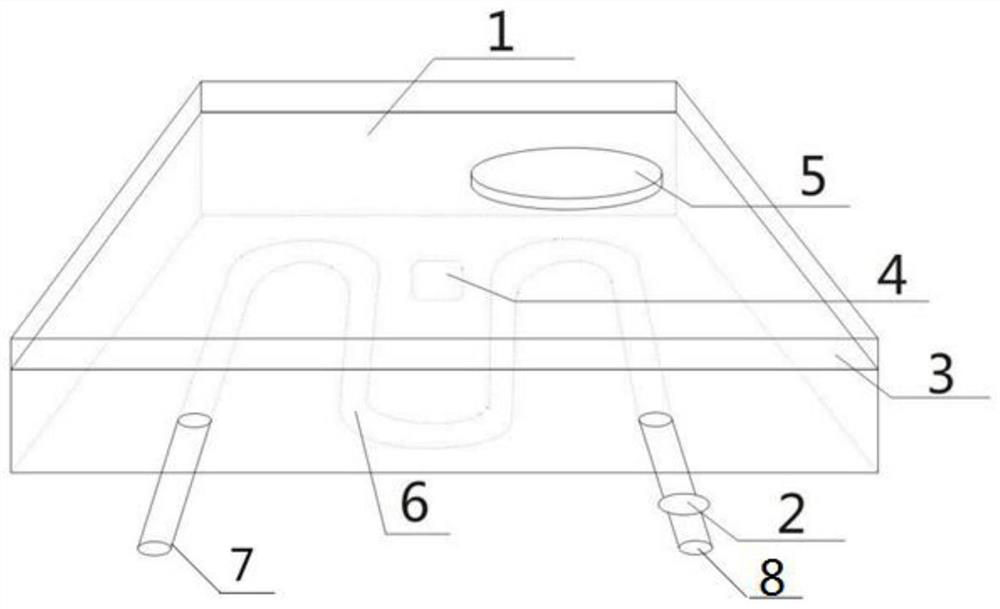

[0038] like figure 1 shown.

[0039] A heat dissipation tool for chip ceramic discs in the LED chip substrate thinning process, including a circulating water tank 1, the upper surface of the circulating water tank 1 is provided with a positioning groove for fixing the ceramic disc, and the shape of the positioning groove is similar to that of ceramic The shape of the plate is corresponding; the upper surface of the circulating water tank 1 is provided with a baffle 3; the baffle 3 is arranged around the circulating water tank 1; the inside of the circulating water tank 1 is provided with a U-shaped heat-absorbing pipe 6, The U-shaped heat-absorbing pipe 6 communicates with the external circulating water through the water inlet pipe 7 and the return water pipe 4 . The positioning groove and the baffle plate 3 can prevent the ceramic disc from sliding down from the upper surface of the circulating water tank 1 . The U-shaped heat-absorbing pipe is convenient for increasing the...

Embodiment 2

[0045] The heat dissipation tooling used for chip ceramic discs in the LED chip substrate thinning process described in Embodiment 1 is different in that the U-shaped heat-absorbing pipe is arranged in contact with the upper surface of the circulating water tank. Setting the U-shaped heat-absorbing pipe in contact with the upper surface of the circulating water tank can improve heat transfer efficiency and work efficiency of the tooling.

Embodiment 3

[0047] A working method for thinning the LED chip substrate by using the ceramic disk heat dissipation tooling described in Embodiment 1 or 2, comprising the following steps:

[0048] 1) SMT operation: heat the SMT ceramic plate, apply wax on the surface of the ceramic plate after the ceramic plate heats up, and carry out the SMT operation of the chip 5 to be thinned; the heating temperature of the ceramic plate is 95° C.;

[0049] 2) Tablet pressing operation: After the placement operation is completed, place the ceramic plate with the chips under the tablet press machine for tablet pressing operation; the tablet pressing pressure is 0.4MPa;

[0050]3) Grinding operation: After the tablet pressing operation is completed, the ceramic disk is adsorbed on the suction cup of the mechanical arm of the grinder to perform the grinding operation of the chip thickness; The speed of the suction cup is 50r / min, and the grinding pressure is 20kg;

[0051] 4) Cleaning operation: After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com