Sand-in-water colorful paint with excellent early water resistance

A technology of multi-color coatings and water resistance, applied in multi-color effect coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as hard to restore, whitening of sand-in-water multi-color coating layers, and difficult to achieve improvement Water resistance, satisfying water resistance, excellent early water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

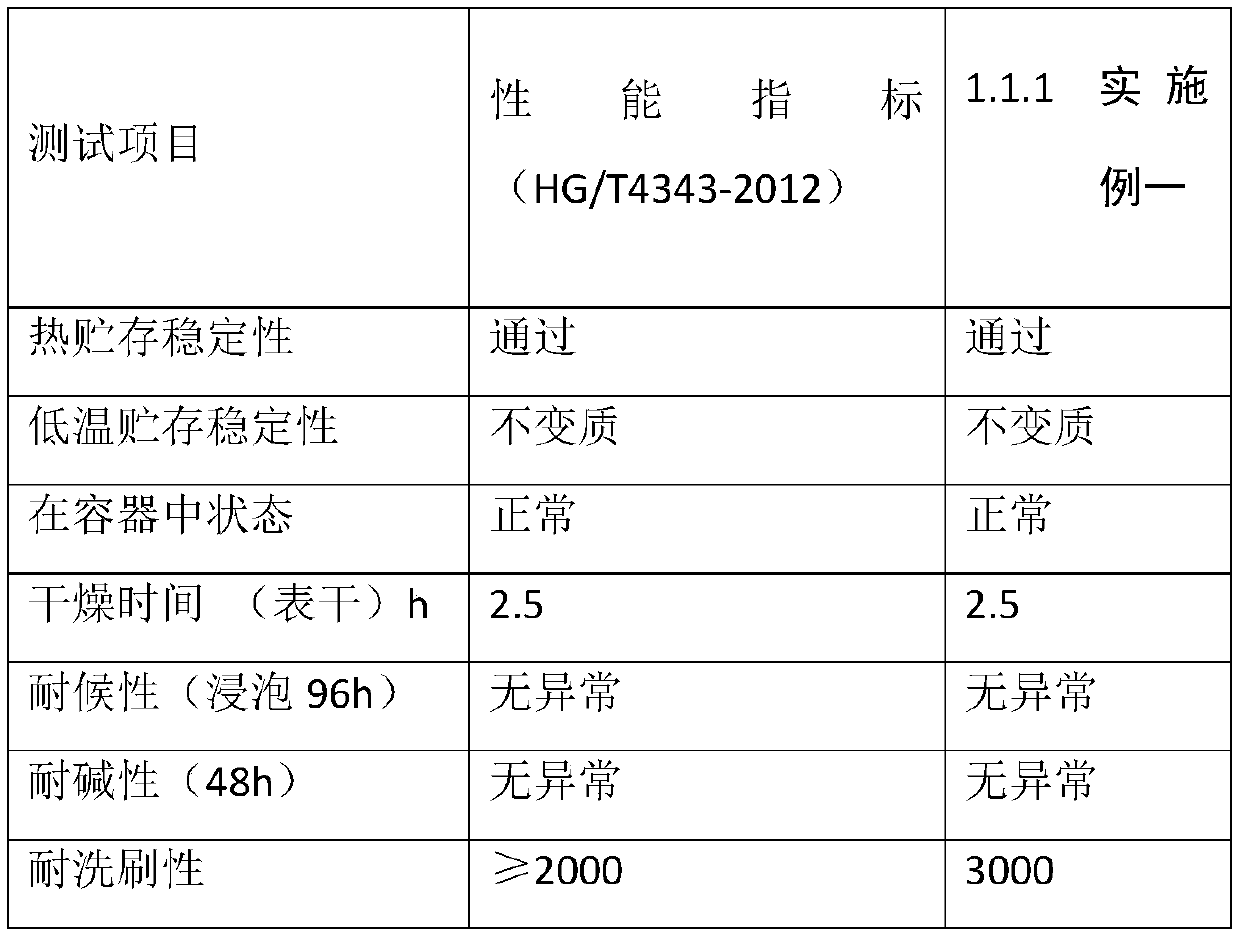

Embodiment 1

[0021] Step 1: Preparation of protective glue

[0022] The raw materials and mass ratio of the protective glue are: 91.8 parts by weight of water, 8 parts by weight of hectorite, first add water to the dispersion tank, add hectorite under the stirring condition of 600-1500r / min, and disperse until fully dissolved without graininess , stand for 2h for later use.

[0023] Step 2: Preparation of base paint

[0024] The raw materials and mass ratio of the base paint are: 40 parts by weight of water; 1.5 parts by weight of hydrophobic modified cellulose; 0.5 parts by weight of antifreeze; 0.1 parts by weight of multifunctional agent; 0.4 parts by weight of dispersant; 0.6 parts by weight of membrane aid; 15 parts by weight of kaolin; 1 part by weight of titanium dioxide; 26 parts by weight of silicon-acrylic emulsion; 2 parts by weight of silicone emulsion; The above raw materials are fully dispersed and evenly prepared to obtain a white base paint.

[0025] Step 3: Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com