Spinning structure for gel filamentation apparatus

A technology of filament forming and equipment, applied in filament/thread forming, feeding solution to spinnerets, textiles and papermaking, etc., it can solve the problem of easy blockage of the spinning hole of spinning disc, poor spinning effect, and easy evaporation of colloid and other problems to achieve the effect of avoiding colloidal solution solidification, saving space and fixing firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

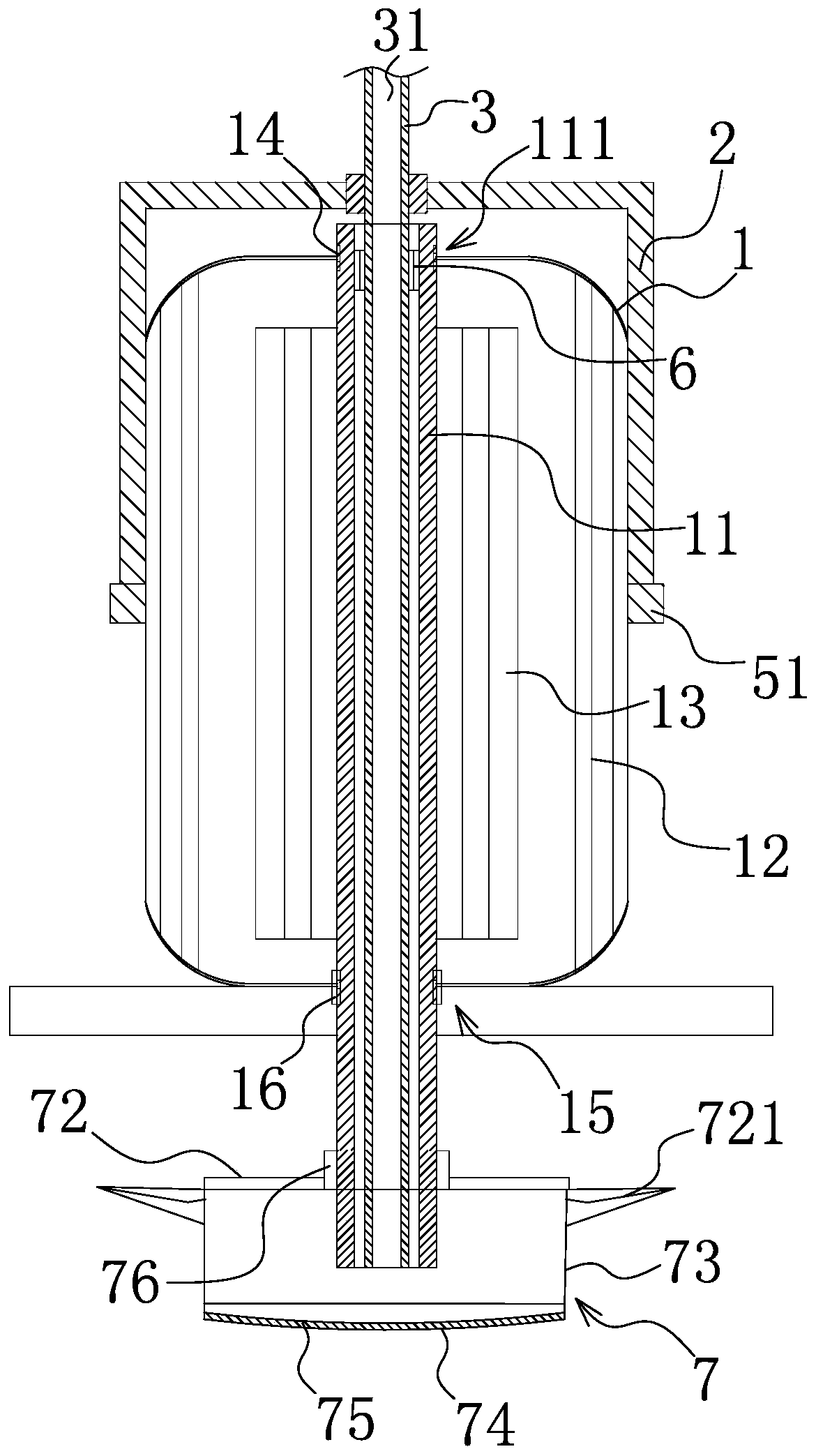

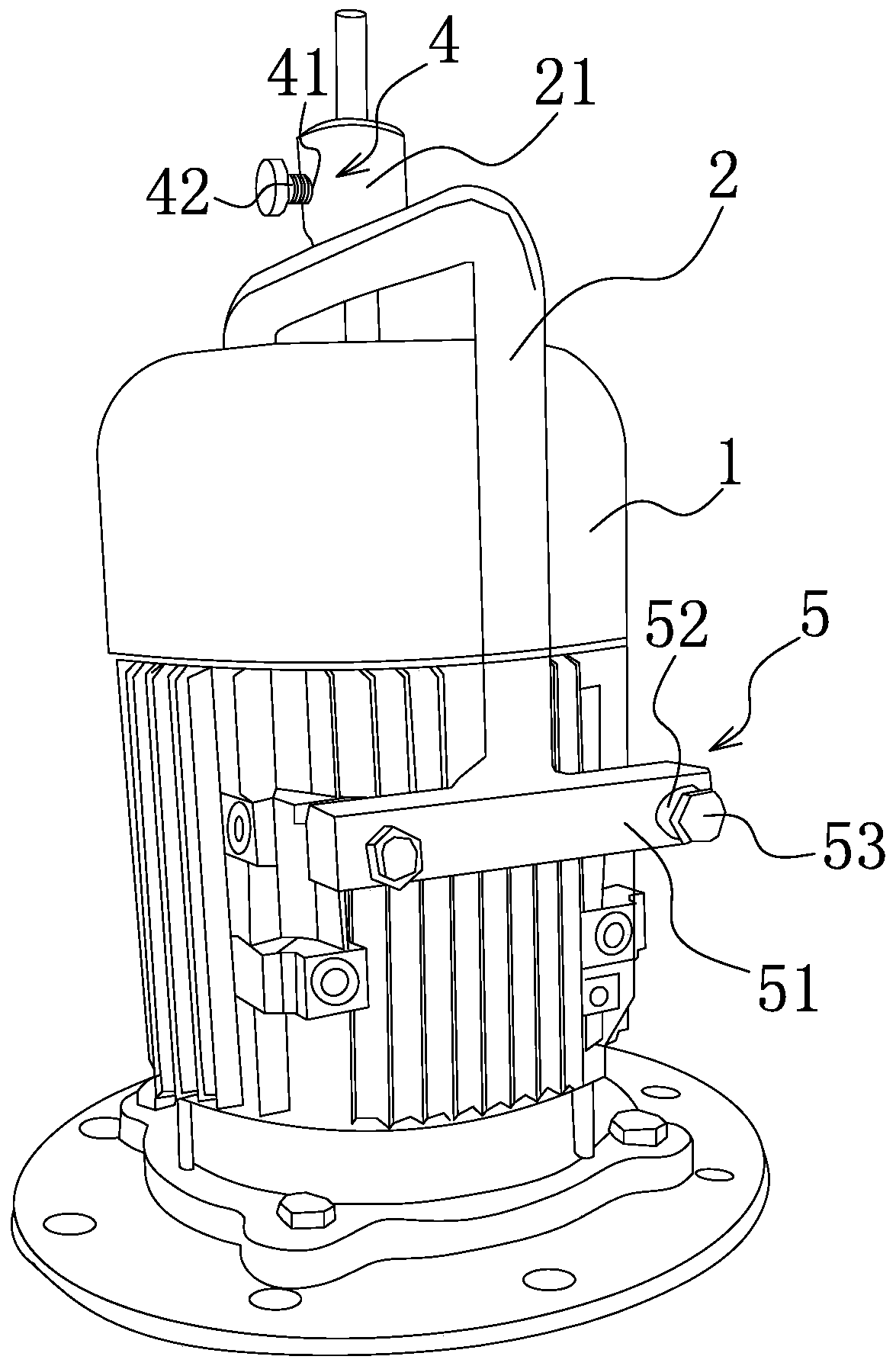

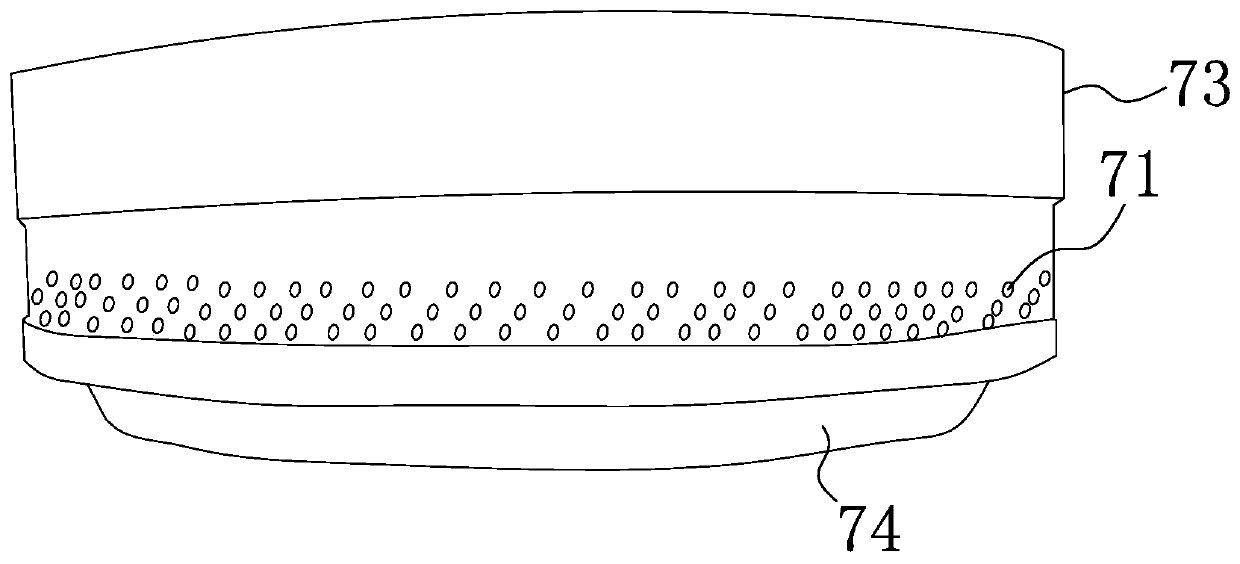

[0022] Such as Figure 1-3 As shown, the spinning structure of the colloidal silk forming equipment includes a spinning disc body 7 arranged directly below the feeding pipe body 3 and connected to the spinning motor shaft 11. The spinning motor shaft 11 is hollow and the feeding tube body 3 The coaxial thread is installed in the spinning motor shaft 11, wherein the feeding pipe body 3 has a feeding channel 31, and the circumferential inner side of the spinning motor shaft 11 is not in contact with the circumferential outer side of the feeding tube body 3, and the spinning motor shaft 11 is opposite to each other. The feeding tube body 3 is rotated in the circumferential direction, the upper end of the spinning disc body 7 is open, and the lower end is closed, and a number of spinning holes 71 are arranged on the outer side of the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com