Thread throwing device of colloidal silk forming equipment

A technology of filament forming and equipment, which is applied in the direction of filament generation, filament/thread forming, feeding solution to spinneret, etc., which can solve the problems of easy sticking together, easy fiber breakage, poor spinning effect, etc., and achieves fixed Strong, space-saving and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

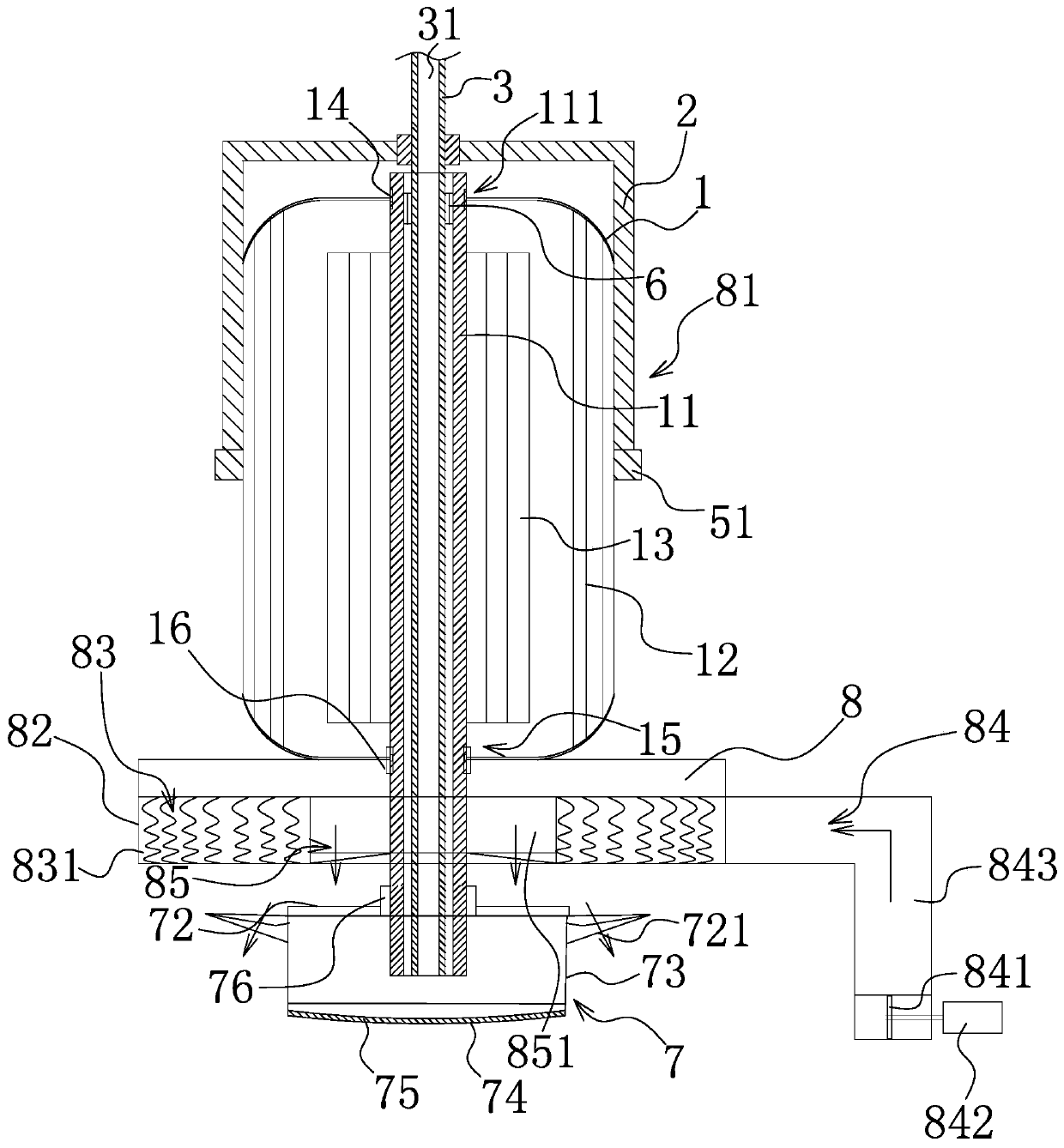

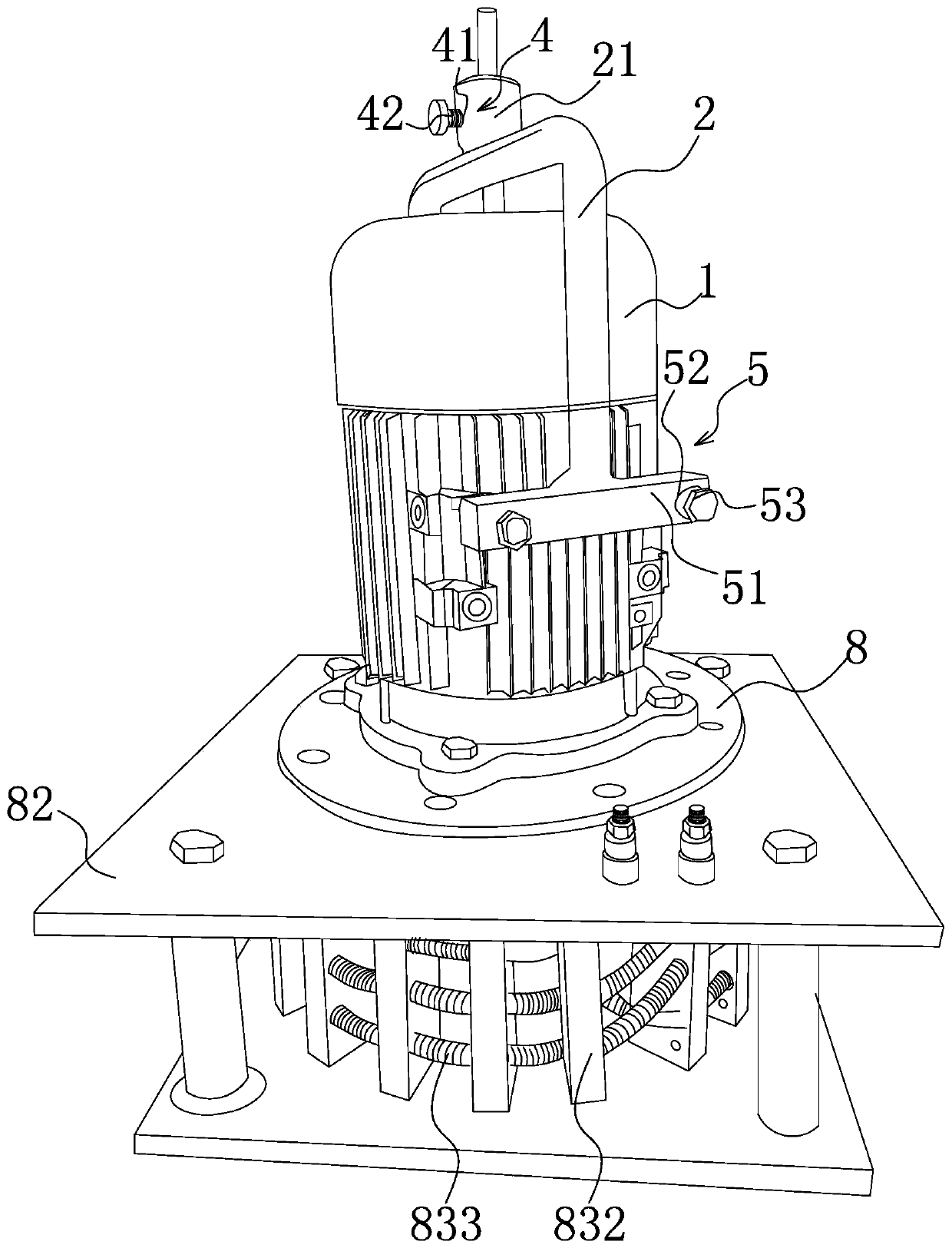

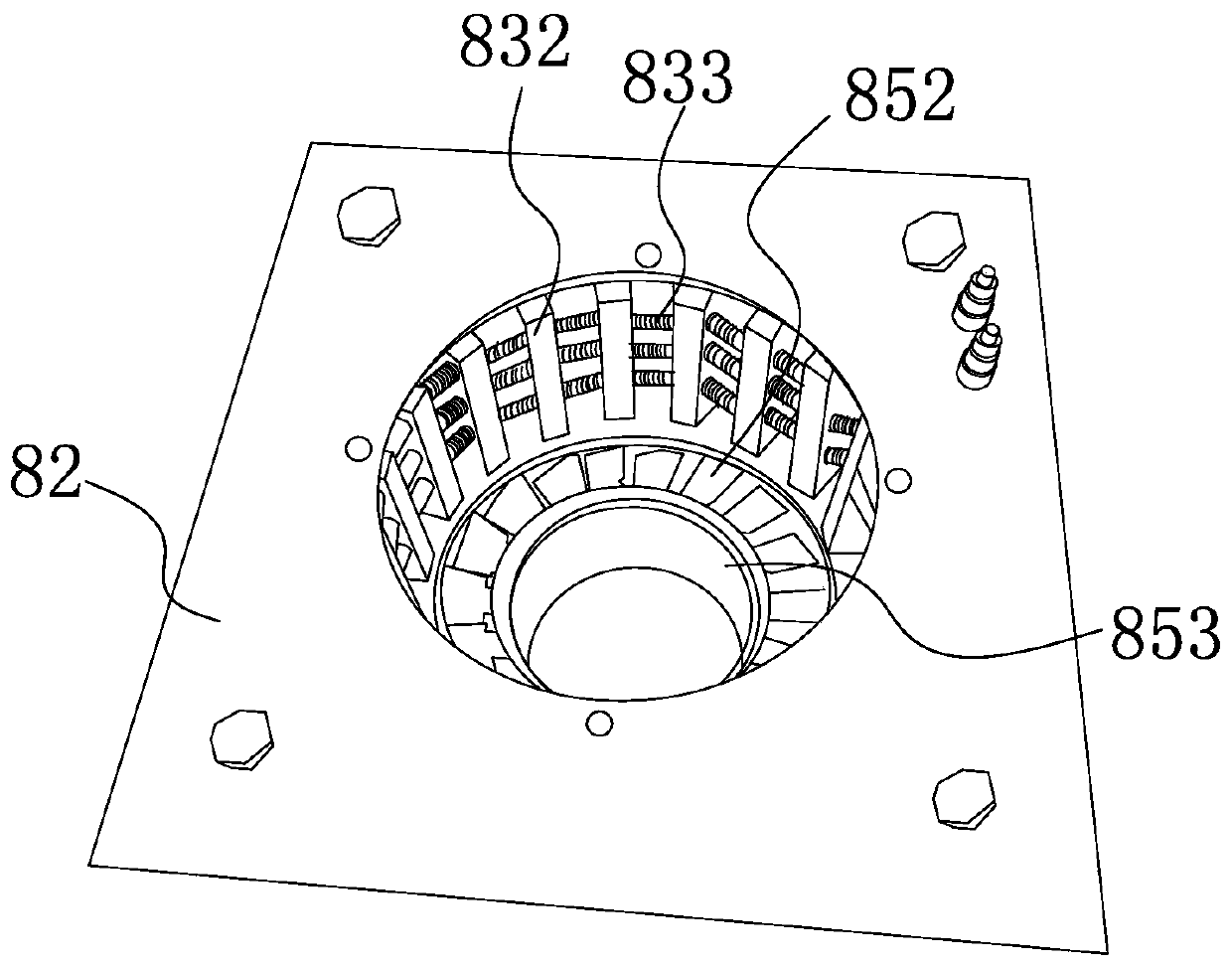

[0027] Such as Figure 1-4 As shown, the spinning device of the colloidal silk forming equipment includes a spinning motor 81 arranged on the spinning seat 8, the motor shaft 11 of the spinning motor 81 is hollow and the motor shaft 11 is provided with a feeding pipe body 3 , there is a feeding channel 31 in the feeding pipe body 3, a hot air seat 82 is provided at the lower end of the spinning seat 8, and a heating assembly 83 is provided in the hot air seat 82, and the heating assembly 83 is connected with a hot air introduction structure 84, and the motor shaft 11 is connected with the feeding pipe body 3. It is installed on the hot air seat 82 and extends to the bottom of the hot air seat 82. The lower end of the motor shaft 11 is connected with a silk spinning disc body 7 corresponding to the feeding pipe body 3 and having severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com