Single-layer microstrip transmission array antenna based on Huygens meta-surface and manufacturing method thereof

A manufacturing method and array antenna technology, applied in antennas, electrical components, waveguide horns, etc., can solve the problems of increasing the complexity of planar transmission array antennas and increasing manufacturing costs, and achieve easier assembly and integration, low cost, and low side lobes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

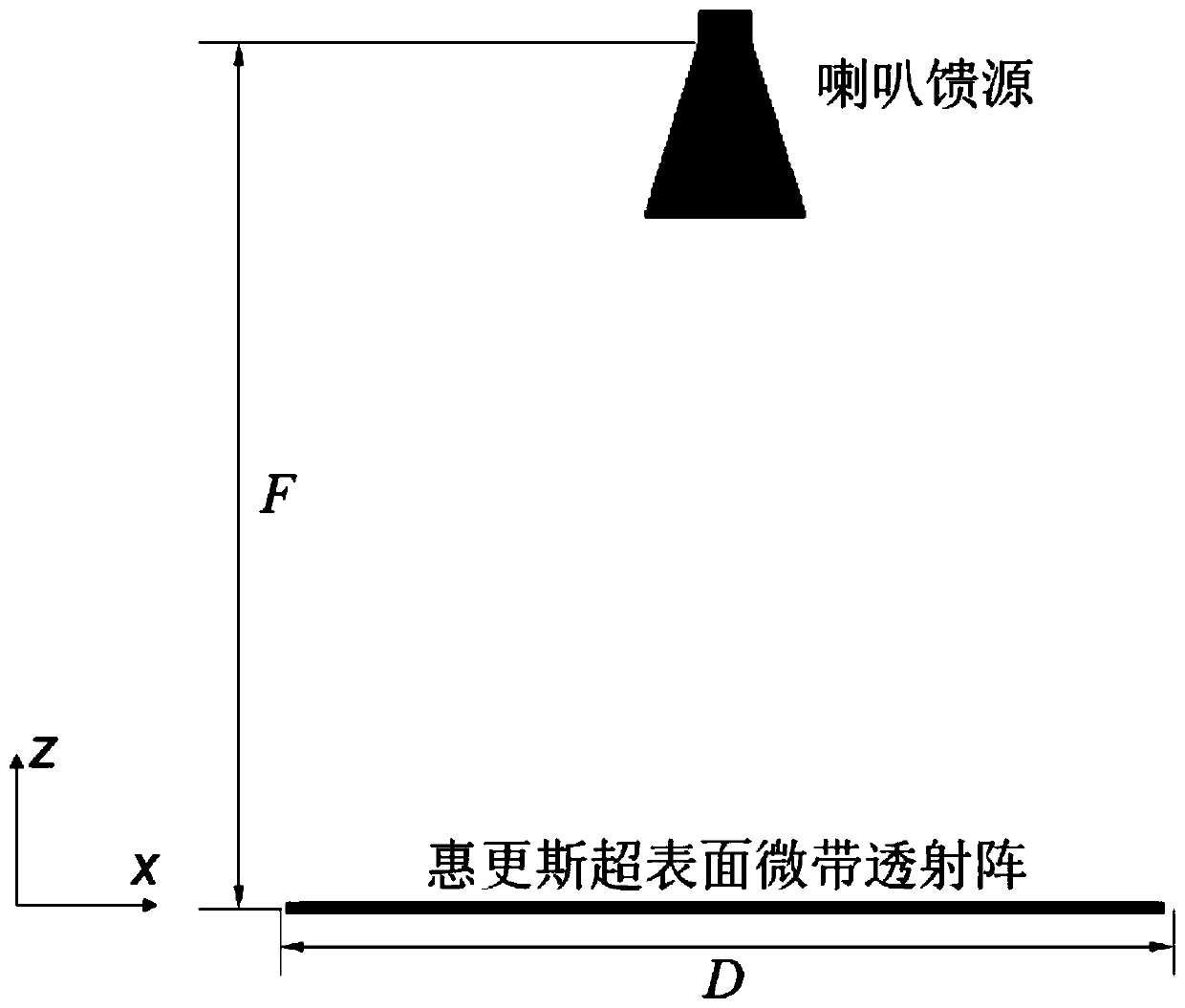

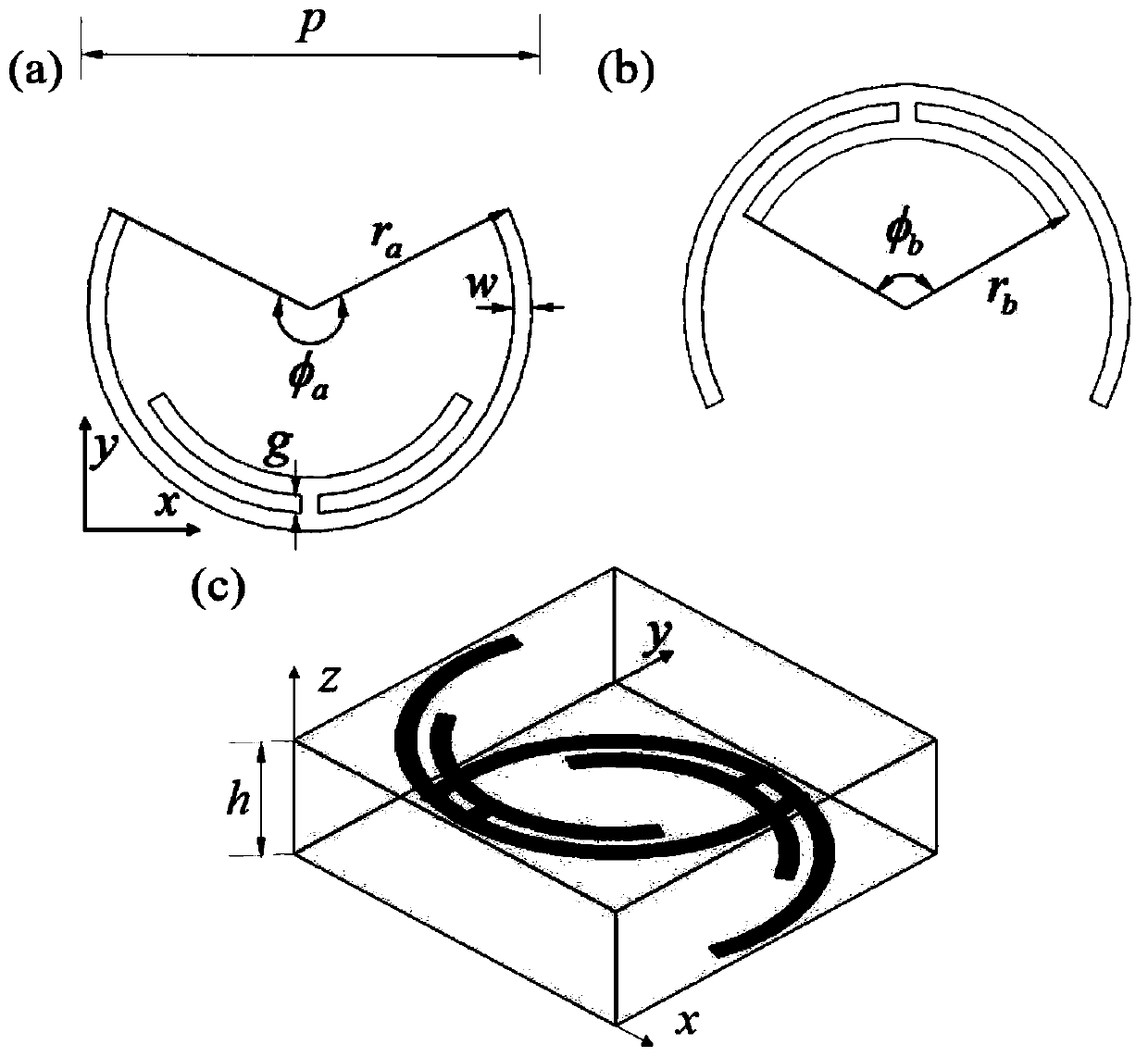

[0027] Such as figure 1 As shown, the single-layer microstrip transmission array antenna provided by the present invention is based on the Huygens metasurface technology, so the present invention discloses a single-layer microstrip transmission array antenna based on the Huygens metasurface, which is fed by a horn Source and Huygens metasurface microstrip transmission array, wherein the horn feed is composed of a waveguide and a horn opening, the waveguide is a standard waveguide BJ260, and the aperture size of the waveguide is a*b=8.636*4.318mm 2 , the opening diameter of the horn is A*B=31*22mm 2 , The overall height of the horn is L=42mm. The distance between the horn opening and the Huygens metasurface microstrip transmission array is F, the aperture of the Huygens metasurface microstrip transmission array is D*D, and the Huygens metasurface microstrip transmission array consists of N*N metasurface transmissions unit composition.

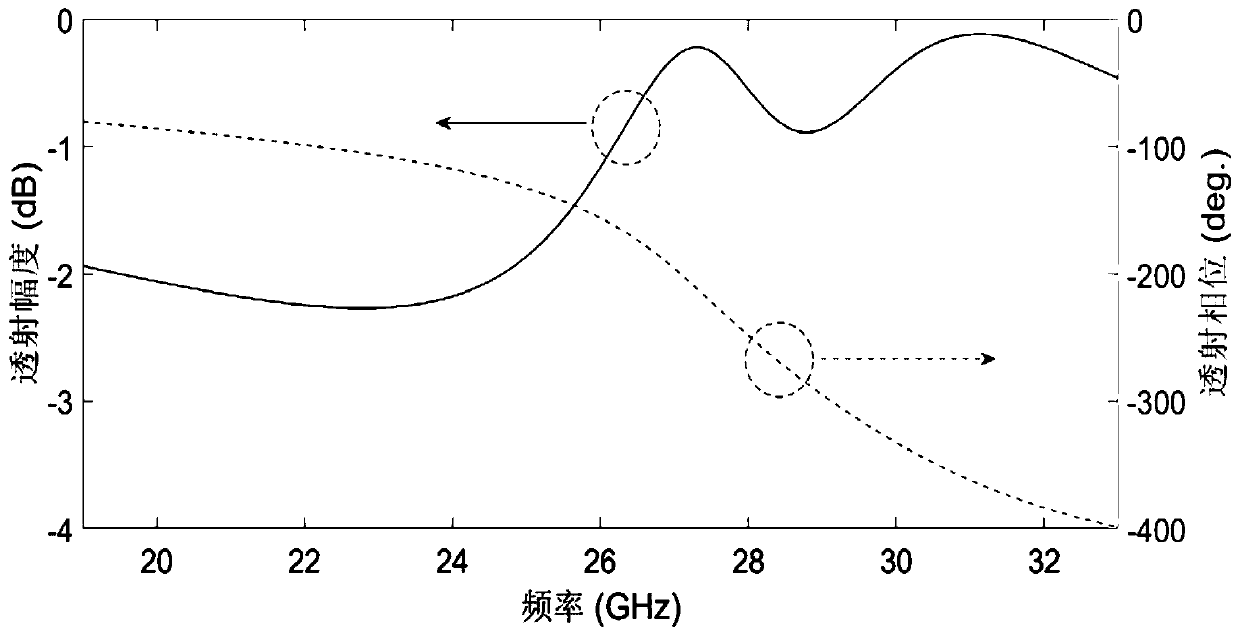

[0028] In order to effectively form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com