Wet curtain solution dehydrator

A dehydrator and wet curtain technology, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of low dehydration efficiency, energy consumption, complex equipment, etc., to save equipment investment, wide application range, dehydration Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0021] The structure of the present invention will be described in detail below with reference to the accompanying drawings.

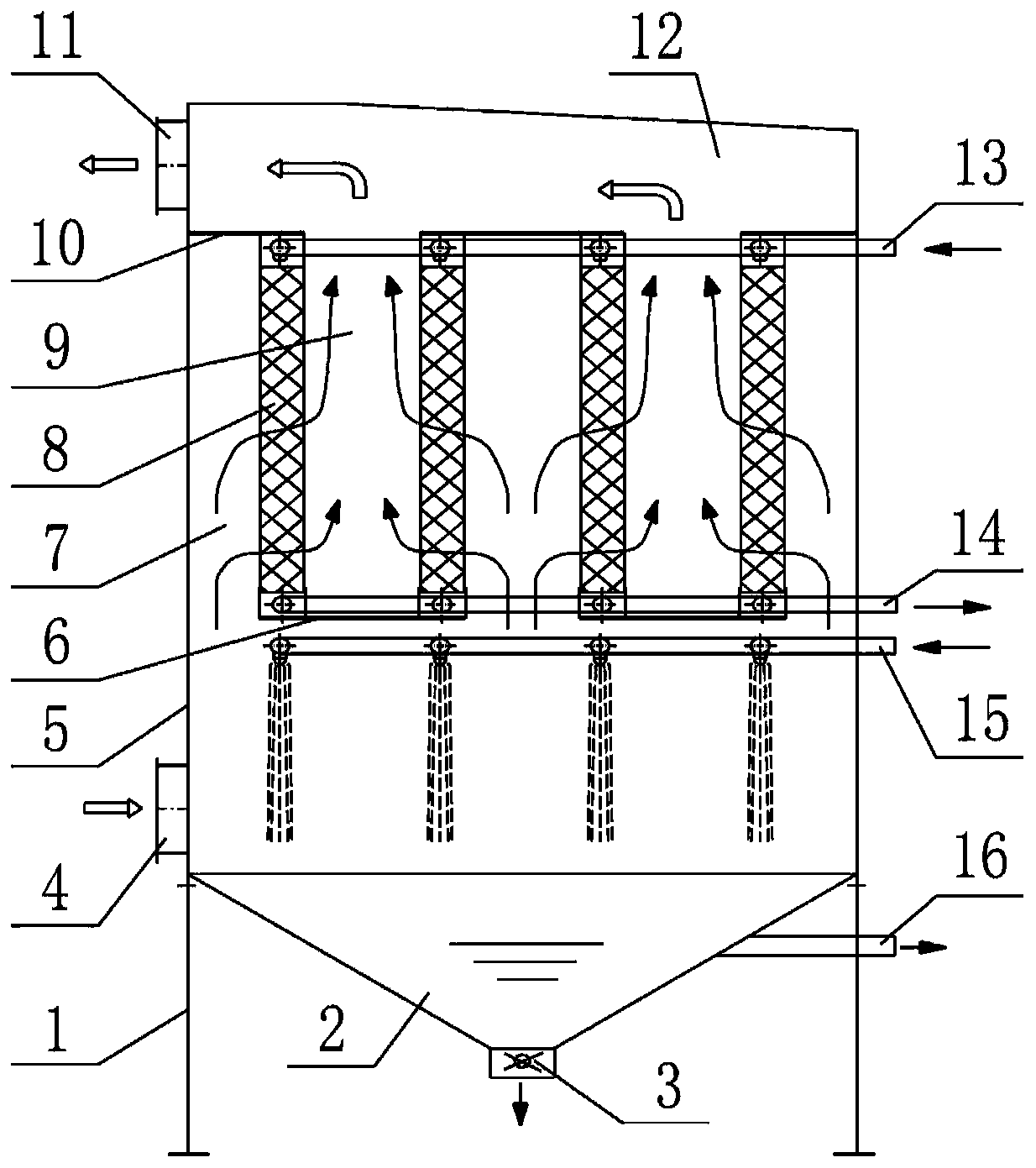

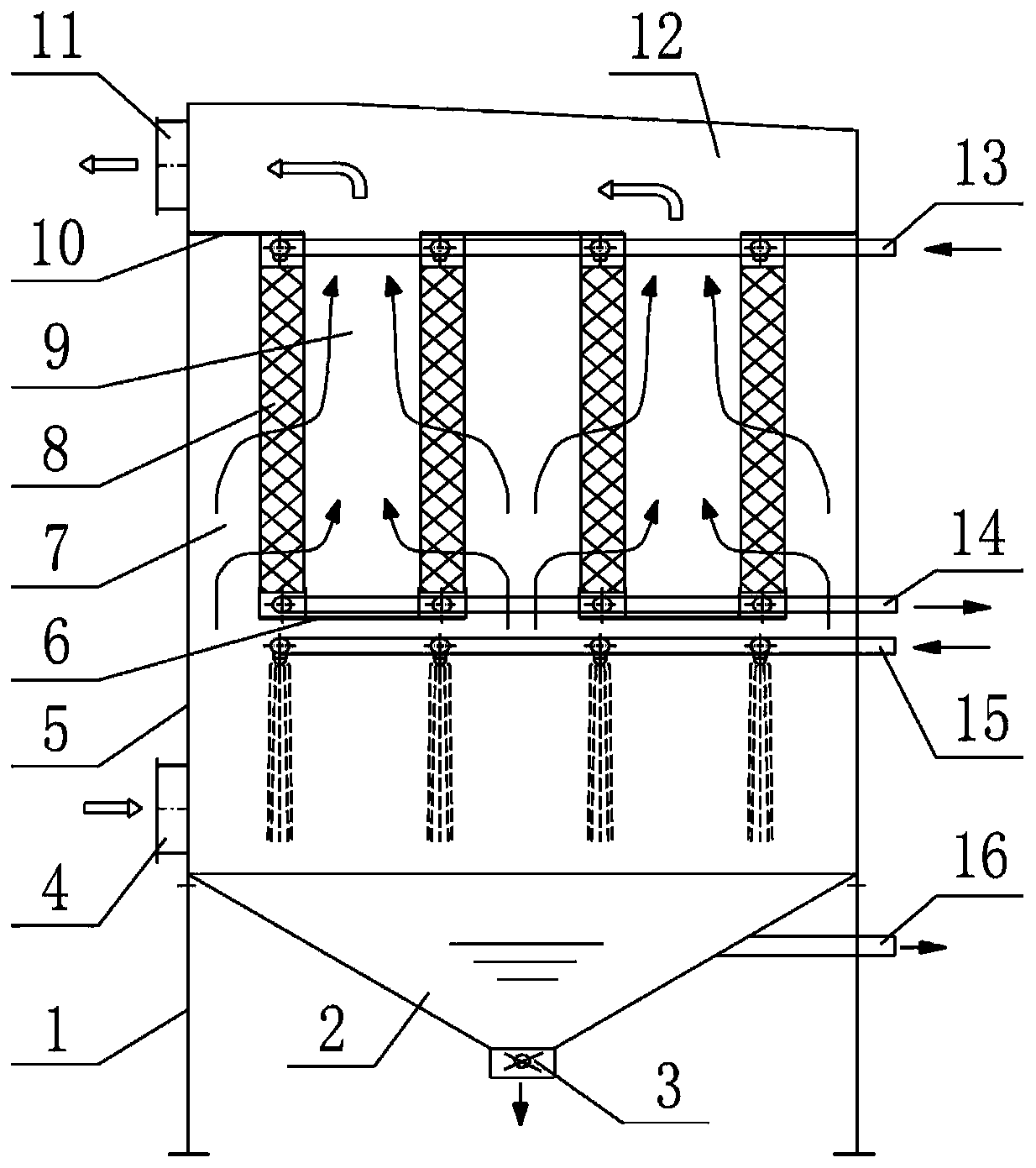

[0022] Such as figure 1 As shown, a wet curtain solution dehydrator of the present invention includes: pillar 1, lower water tank 2, drain valve 3, gas inlet 4, wall plate 5, lower flower plate 6, moisture channel 7, wet curtain assembly 8, dry Gas channel 9, upper flower plate 10, gas outlet 11, upper gas header 12, concentrated solution supply system 13, dilute solution drain system 14, water spray system 15 and overflow pipe 16.

[0023] The dehydrator adopts an integrated structure of water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com