Electrode rotary type DBD reactor

A rotary reactor technology, applied in the field of DBD reactors, can solve the problems of poor speed control accuracy of low-voltage electrode plates, inability to form annular gas control, small moving range, etc., to achieve convenient observation, small footprint, and gas The effect of convenient gap adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

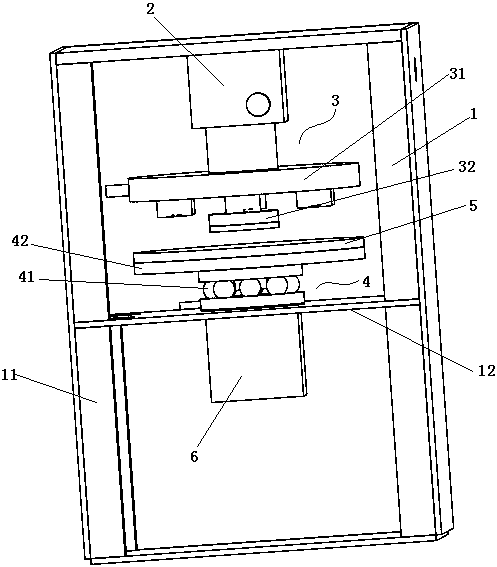

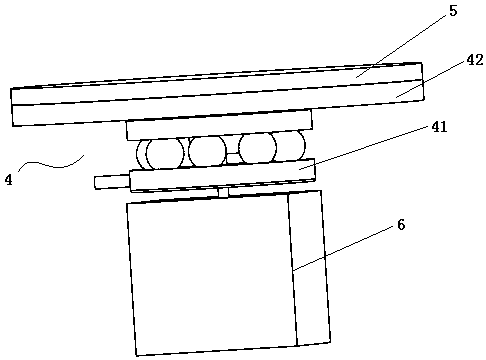

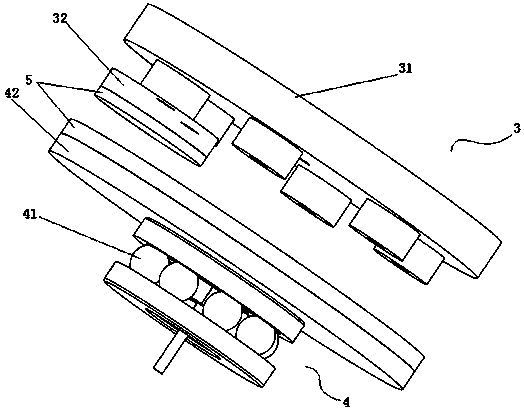

[0024] Such as Figure 1 to Figure 4 An electrode rotating DBD reactor shown includes a frame 1 , a vertical lifting platform 2 , a high-voltage electrode module 3 , a low-voltage electrode module 4 , an insulating medium 5 and a rotating motor 6 .

[0025] The frame 1 has a cuboid structure and the frame is sealed 11 by a plate; a partition 12 is horizontally arranged in the frame 1 to divide the interior of the frame 1 into an upper cavity and a lower cavity; the vertical lifting platform 2 is arranged on the frame 1 In the cavity and connected to the top sealing plate 11 of the frame 1.

[0026] The high-voltage electrode module 3 includes a high-voltage electrode adapter plate 31 and a high-voltage electrode plate 32; the high-voltage electrode adapter plate 31 is hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com