Inner spline part key side positioning spline expansion device and machining process thereof

A technology of tensioning device and internal spline, applied in the direction of expanding the mandrel, can solve the problems of low efficiency and difficult positioning, and achieve scientific structure design, simple and convenient production and processing technology, and ensure positioning accuracy and tensioning force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

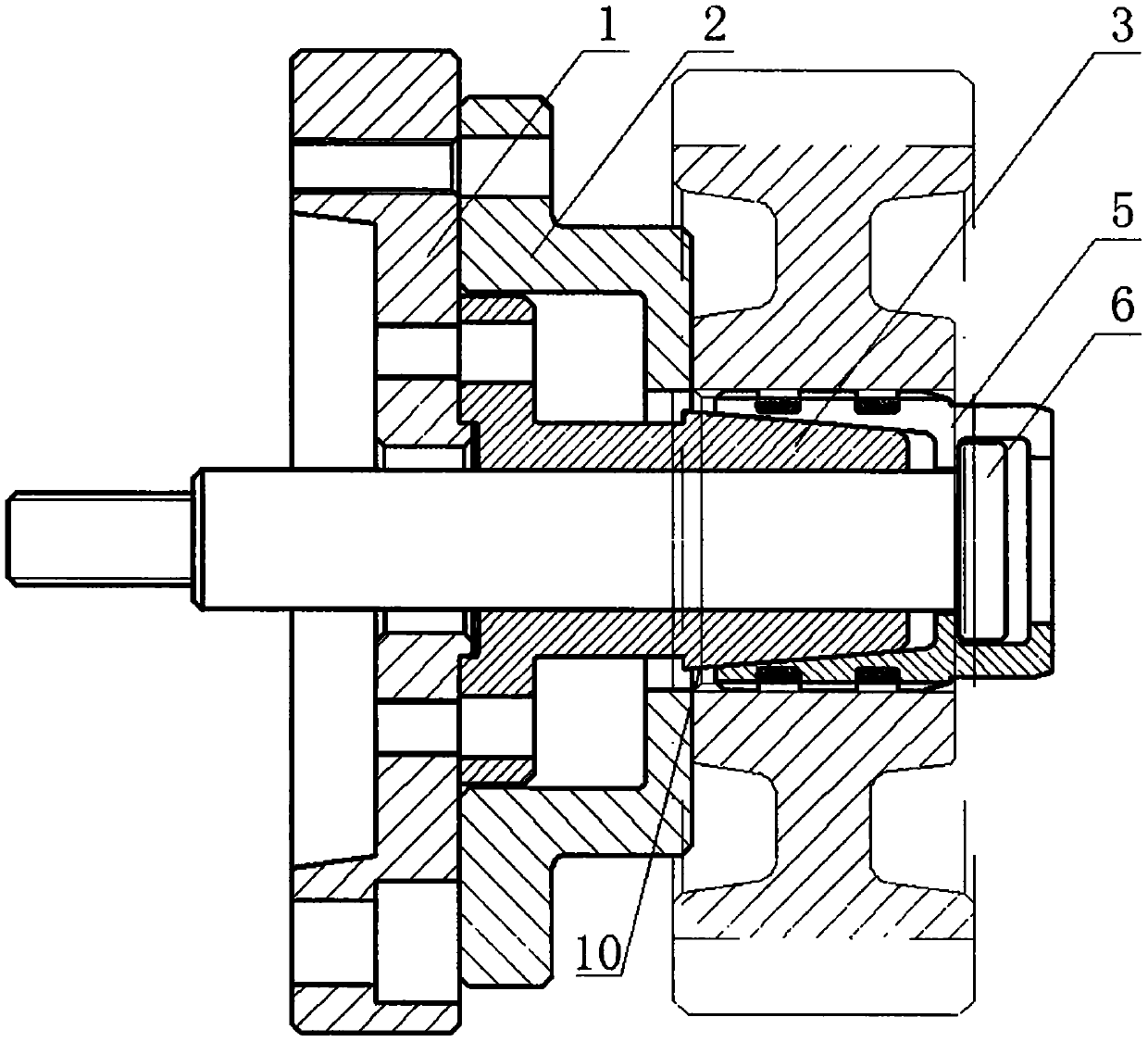

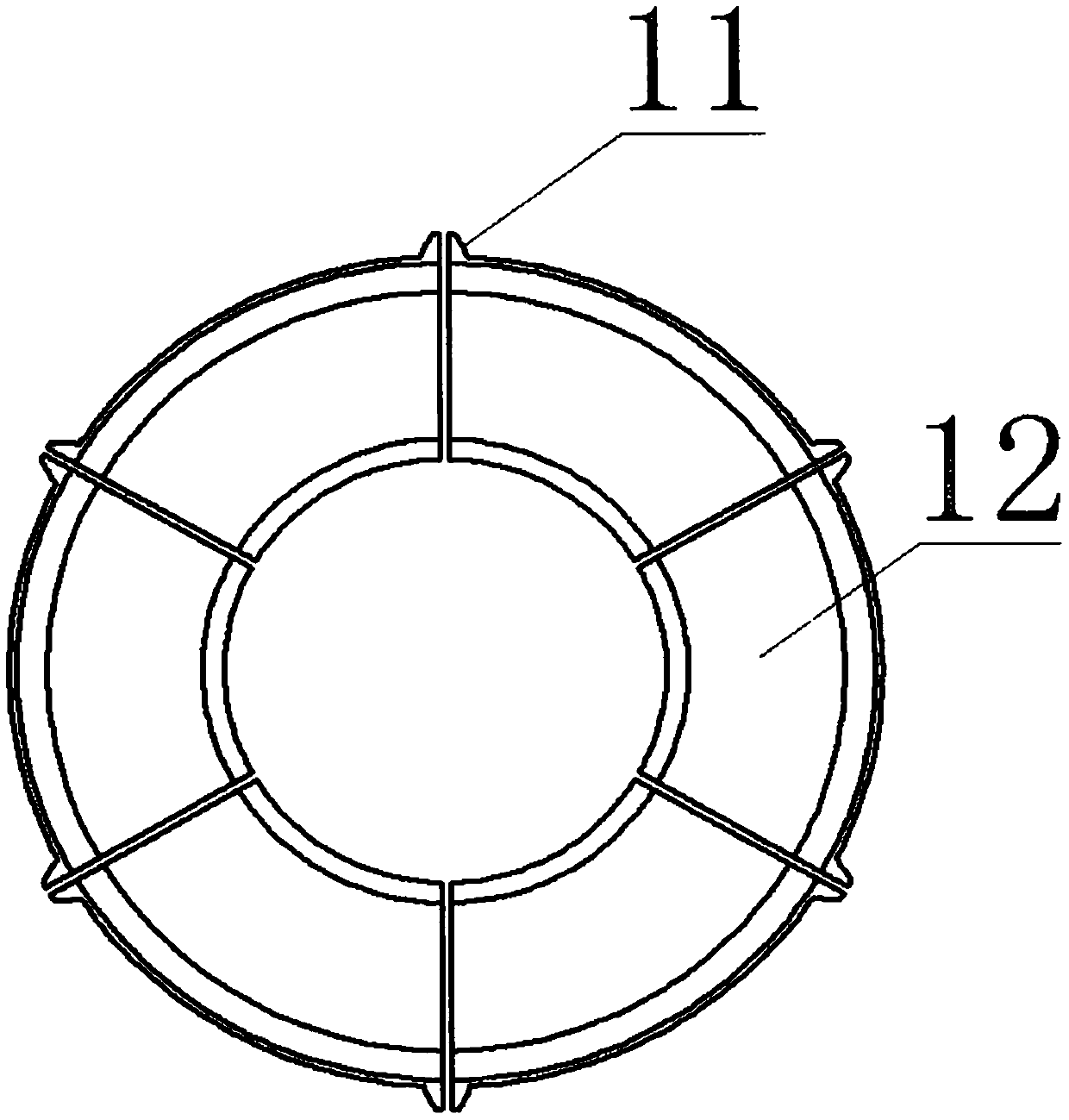

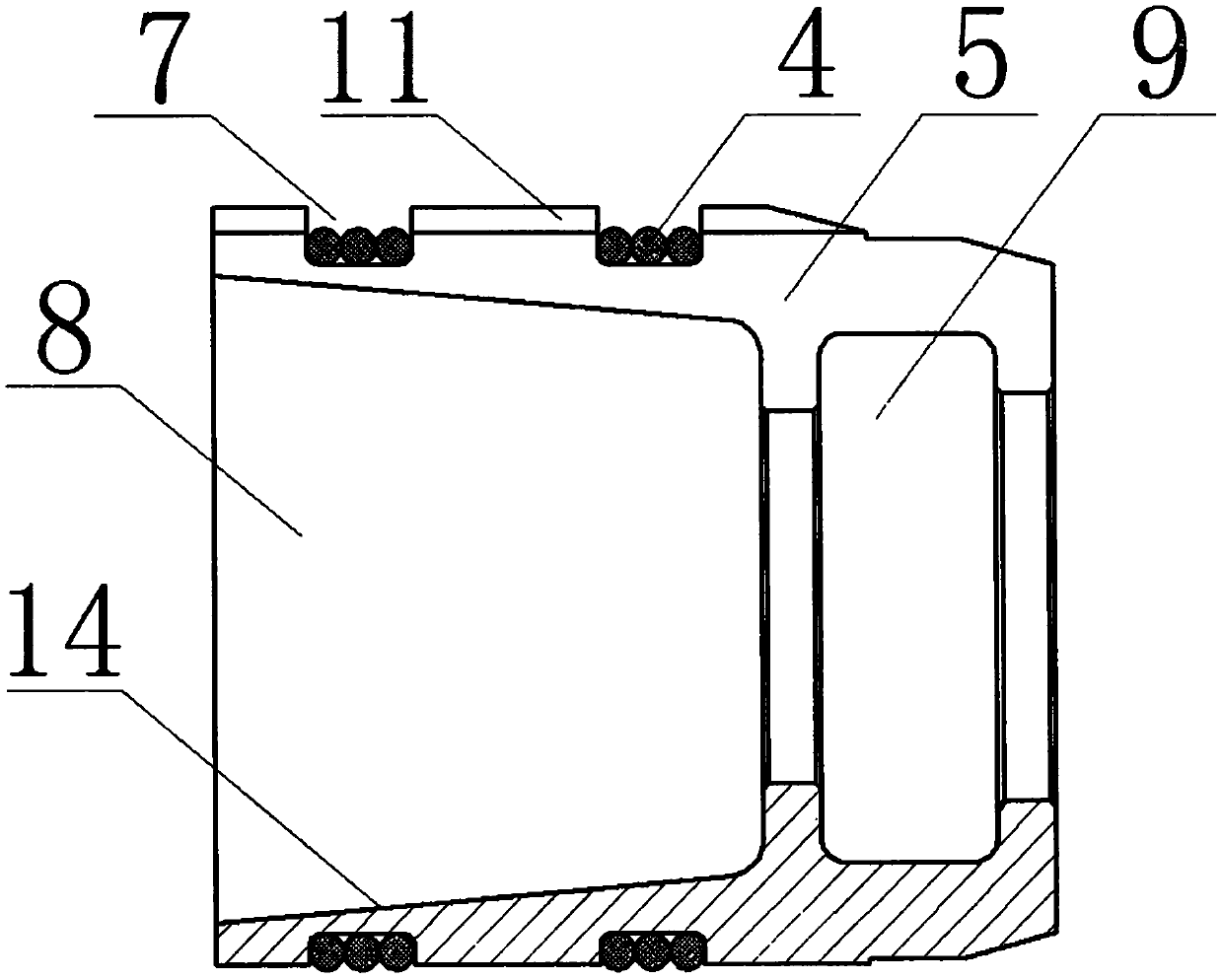

[0022] Specific embodiment 1: below in conjunction with explanation figure 1 , attached figure 2 , attached image 3 and instructions attached Figure 4 The best implementation mode of the present invention is described further:

[0023] In order to solve the problem of difficult positioning existing in the current processing of disk parts with involute spline holes, repeated measurement and processing are required during the processing, which is inefficient, and furthermore, it cannot satisfy people's needs for parts with involute spline holes. In order to solve the problem of the processing and use requirements of disc parts with spline holes, the present invention provides a key side positioning spline tensioning device for internal spline parts and its processing technology. The technical scheme is as follows: a key side of internal spline parts The positioning spline tensioning device includes a flange 1, an axial positioning body 2, a tapered radial positioning body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com