Integrated distributing machine for concrete

A distributing machine and concrete technology, applied in the field of housing construction, can solve problems such as single function, achieve the effects of less transportation times, ensure practicality, and improve efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

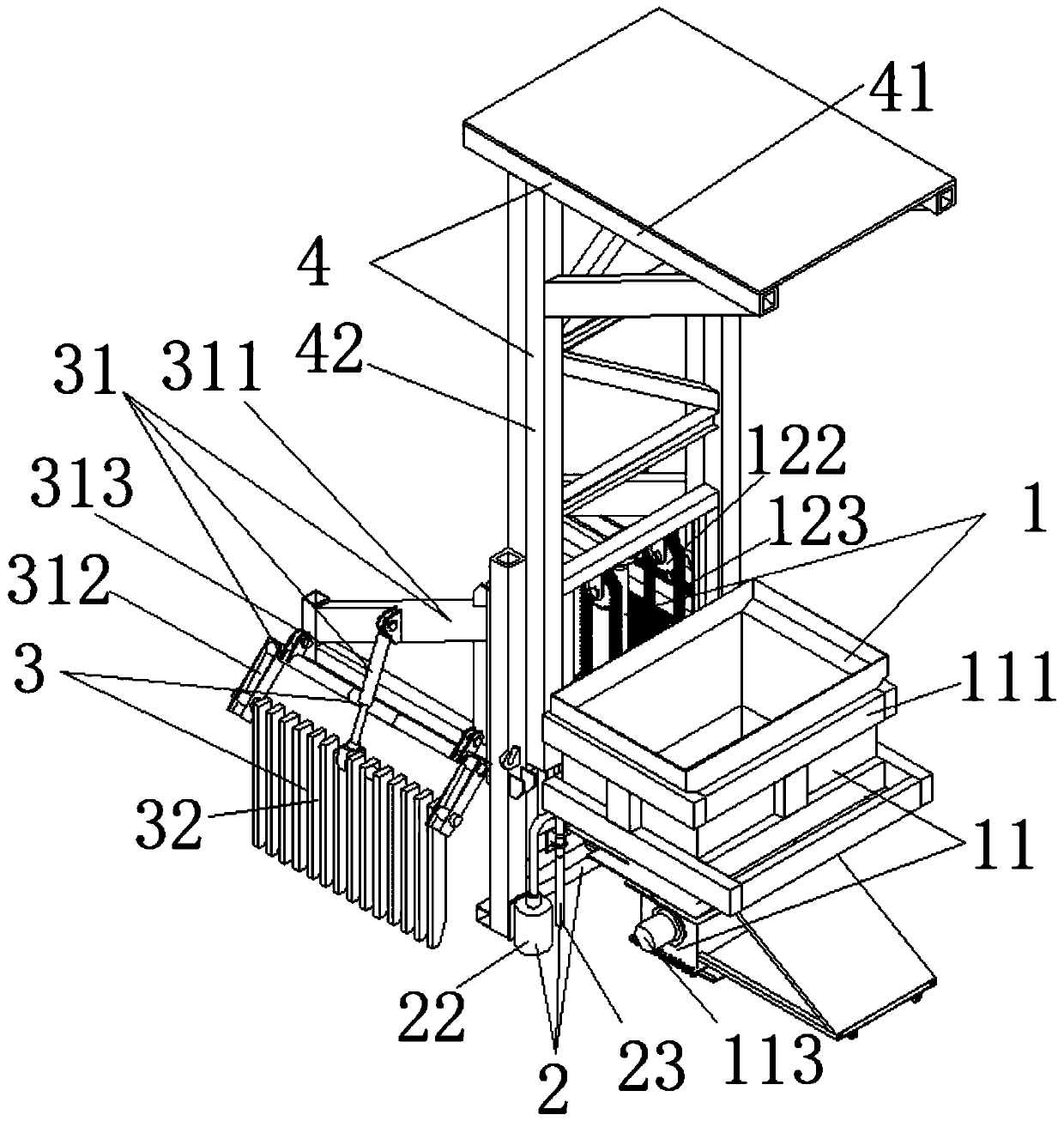

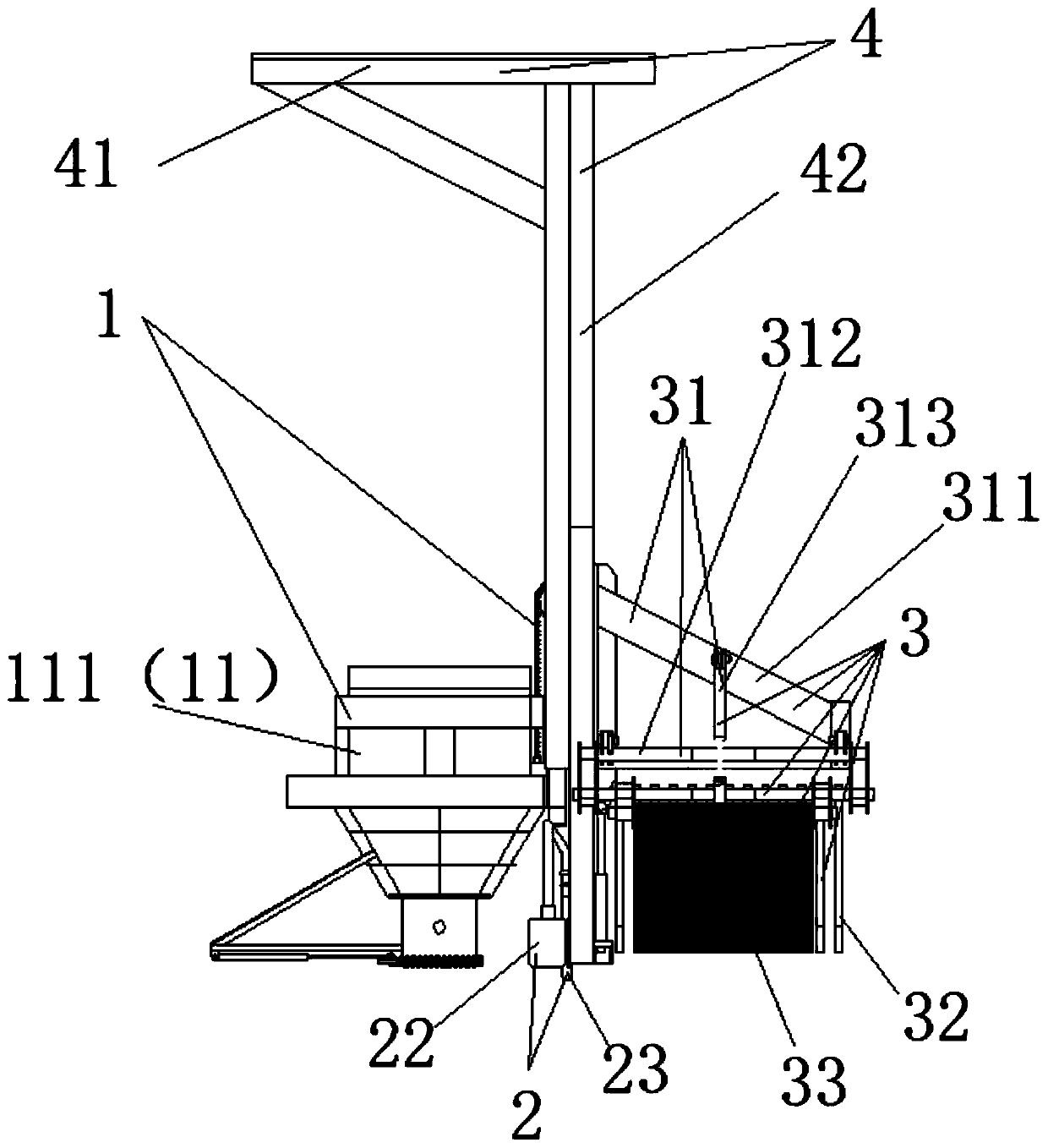

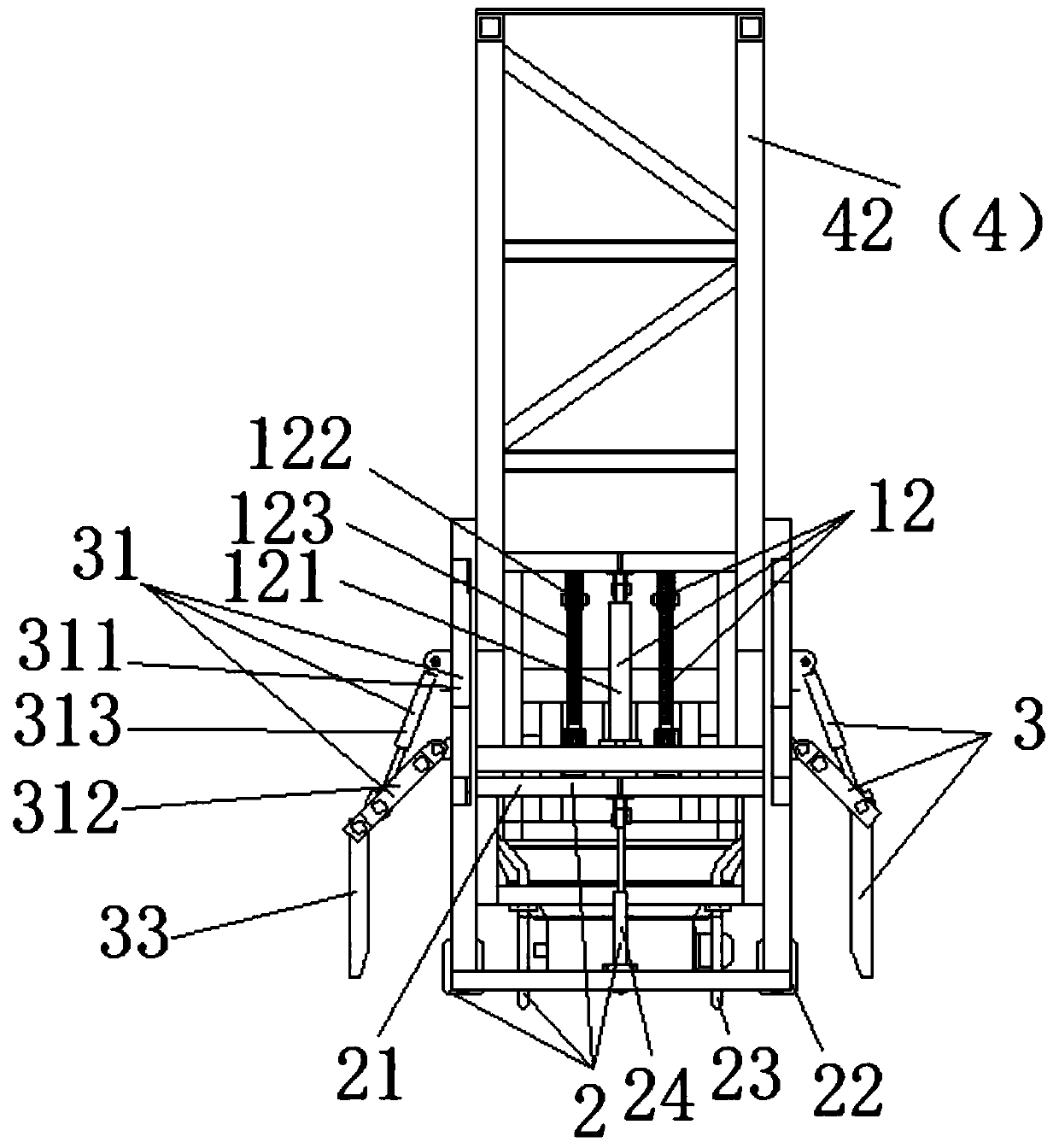

[0047] An integrated distribution machine for concrete provided by the present invention, the distribution machine includes a distribution frame body 4 and a distribution mechanism 1, a vibrating mechanism 2 and a napping mechanism 3 arranged on the distribution frame body 4,

[0048] The distribution frame body 4 includes a distribution frame body crossbeam 41 and a distribution frame body column 42, and the distribution frame body crossbeam 41 is used to be connected with the double-beam crane. The distribution frame body crossbeam 41 is hinged and fixed on the corresponding mobile trolley frame body on the double-beam carriage by 4 pins, and the mobile trolley drives the distribution chassis body 4 to move along the direction of the double-beam carriage box girder.

[0049] The material distribution mechanism 1 includes a square hopper 11 and a hopper lifting system 12 , and the square hopper 11 includes a hopper body 111 , a hydraulic discharge device 112 and a turbine stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com