Process for deep concentration of high-concentration brine

A technology of concentrated brine and high brine, applied in water/sewage treatment, water/sludge/sewage treatment, osmotic/dialysis water/sewage treatment, etc., can solve the problem of inability to further improve concentrated brine, reduce costs, reduce effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

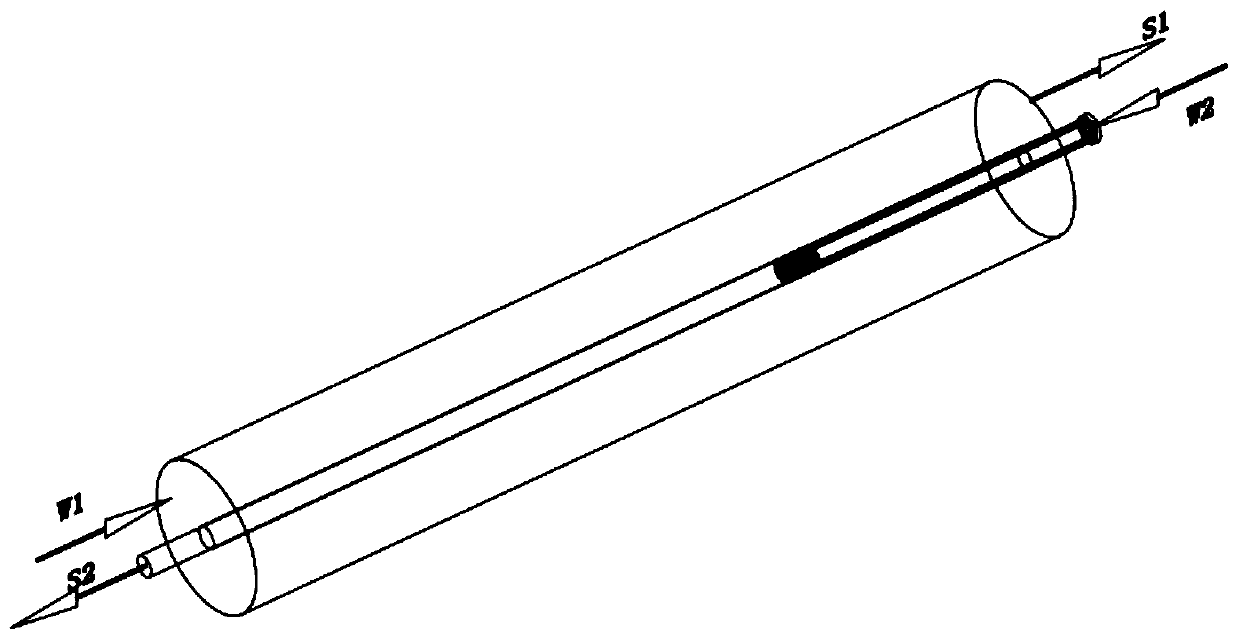

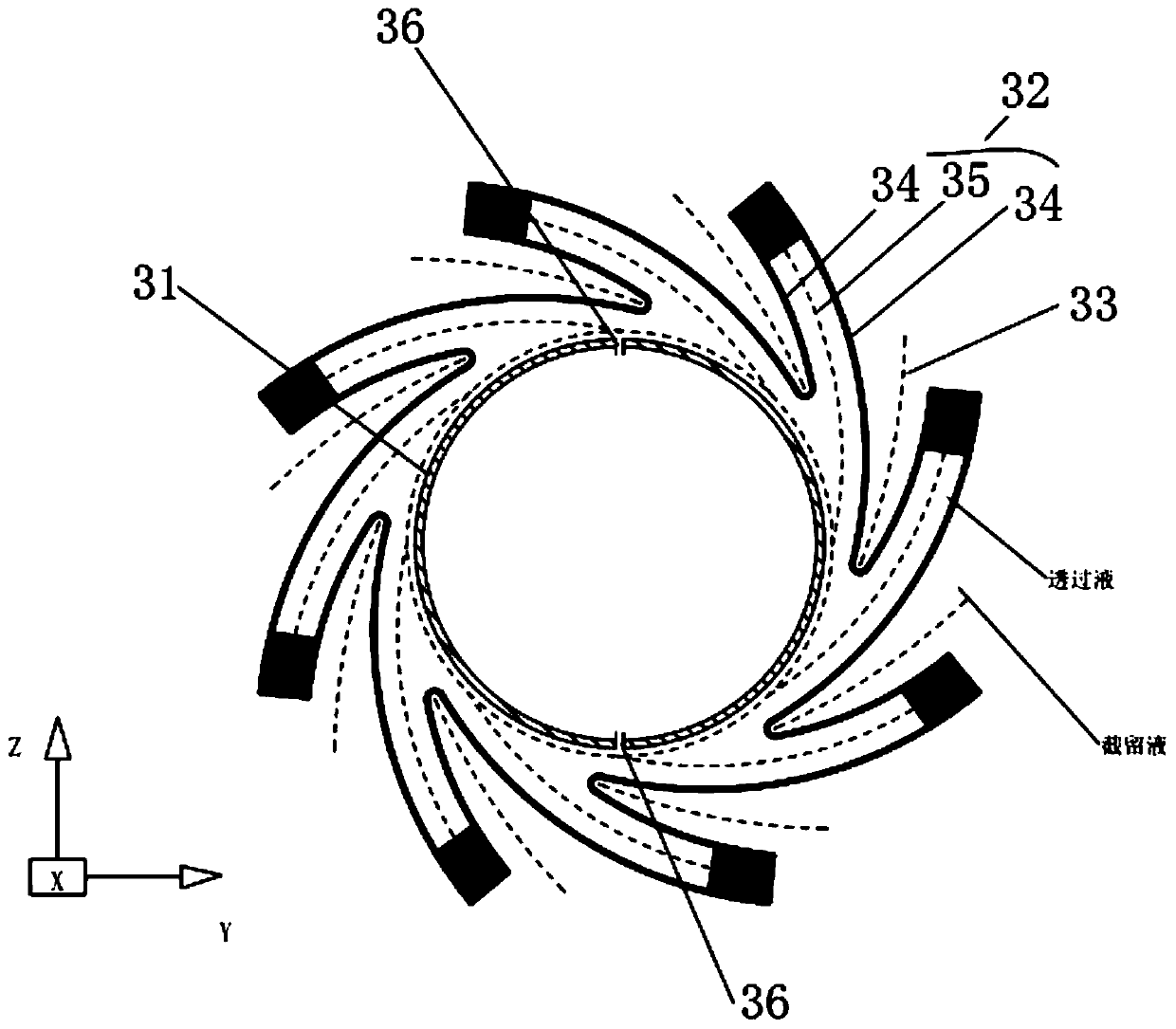

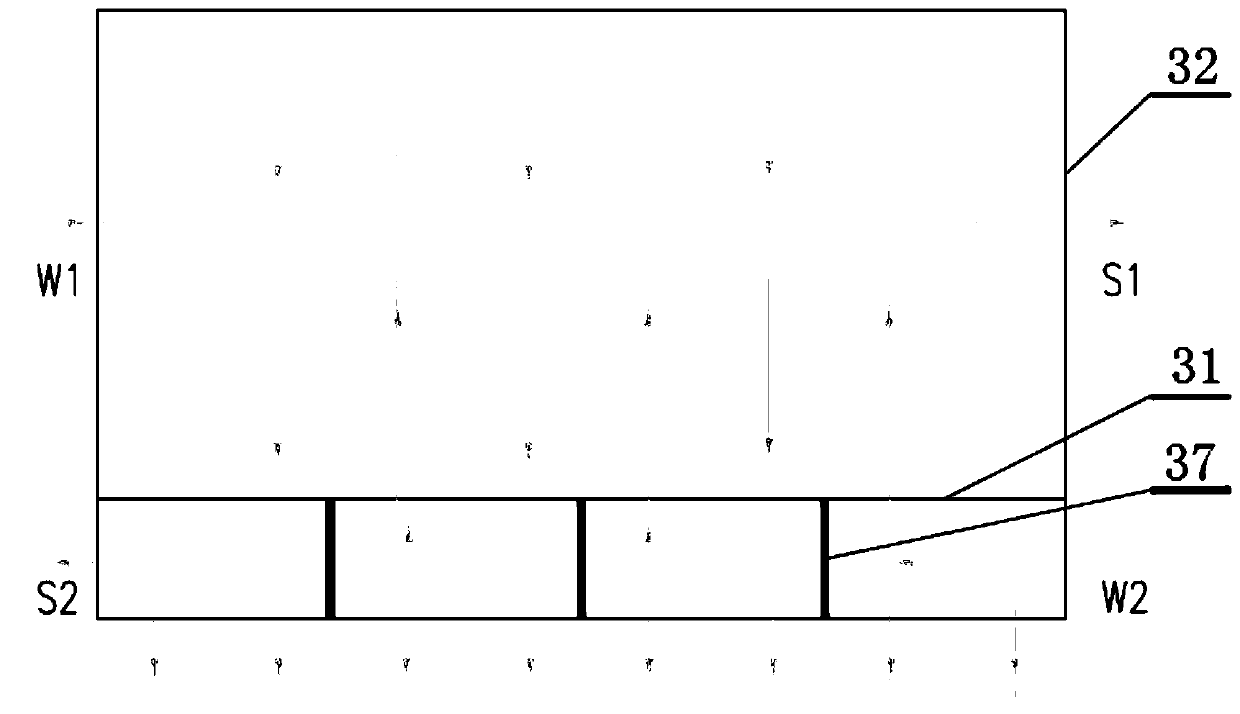

Image

Examples

Embodiment 1

[0065] The TDS of the inlet side of the KFRO membrane is 30000mg / L brine, the main component is sodium chloride and contains a small amount of pollutants, and the operating pressure is 60bar. (Conventional membrane concentration process, TDS can be concentrated to 120000mg / L.) Through the KFRO membrane, it can be one-stage or multi-stage KFRO membrane, and the concentrated brine with TDS of 200000mg / L is obtained. After the concentrated brine is collected, part of the concentrated brine is evaporated and crystallized, and part The concentrated water side of the KFRO membrane enters the KFRO membrane to obtain dilute brine. The dilute brine enters the reverse osmosis membrane, which can be one-stage or multi-stage reverse osmosis, and the filtrate can be reused. The concentrated solution is mixed with brine with a TDS of 30,000mg / L and then enters the KFRO membrane to continue to concentrate.

Embodiment 2

[0067]The TDS of the KFRO membrane inlet side is 70000mg / L brine, the main component is sodium sulfate and contains a small amount of pollutants, and the operating pressure is 65bar. After passing through the KFRO membrane, a concentrated brine with a TDS of 300,000mg / L is obtained. After the concentrated brine is collected, part of it is evaporated and crystallized, and part of it is mixed with dilute brine, and the TDS is 120,000mg / L. It enters the nanofiltration membrane, which can be one-stage or multi-stage nanofiltration, and the filtrate is reused. The dope is mixed with brine with a TDS of 70,000mg / L and then enters the KFRO membrane to continue to concentrate.

Embodiment 3

[0069] The TDS on the inlet side of the KFRO membrane is 100,000mg / L brine, and the operating pressure is 70bar. Through the KFRO membrane, concentrated brine with a TDS of 200,000mg / L is obtained, and the concentrated brine is collected and evaporated to crystallize. The brine concentrated by the reverse osmosis membrane enters the KFRO membrane from the concentrated water side of the KFRO membrane, and the dilute brine obtained enters the reverse osmosis membrane, and the filtrate is reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com