Technical process for treating air conditioner coating waste water

A technology for coating wastewater and process flow, applied in water/sewage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. The effect of improving living environment and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

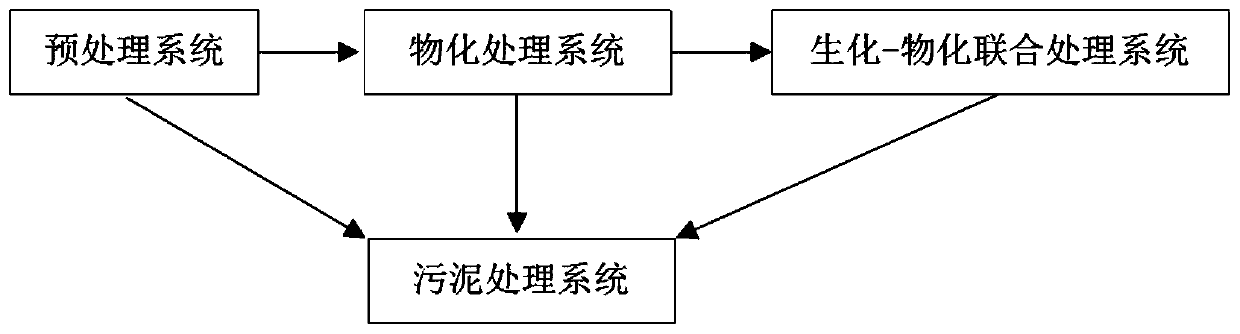

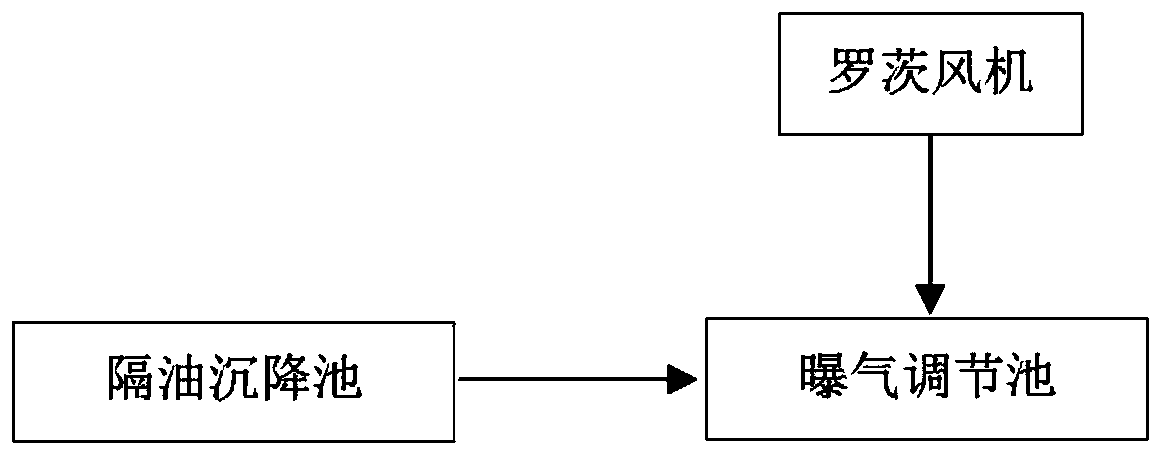

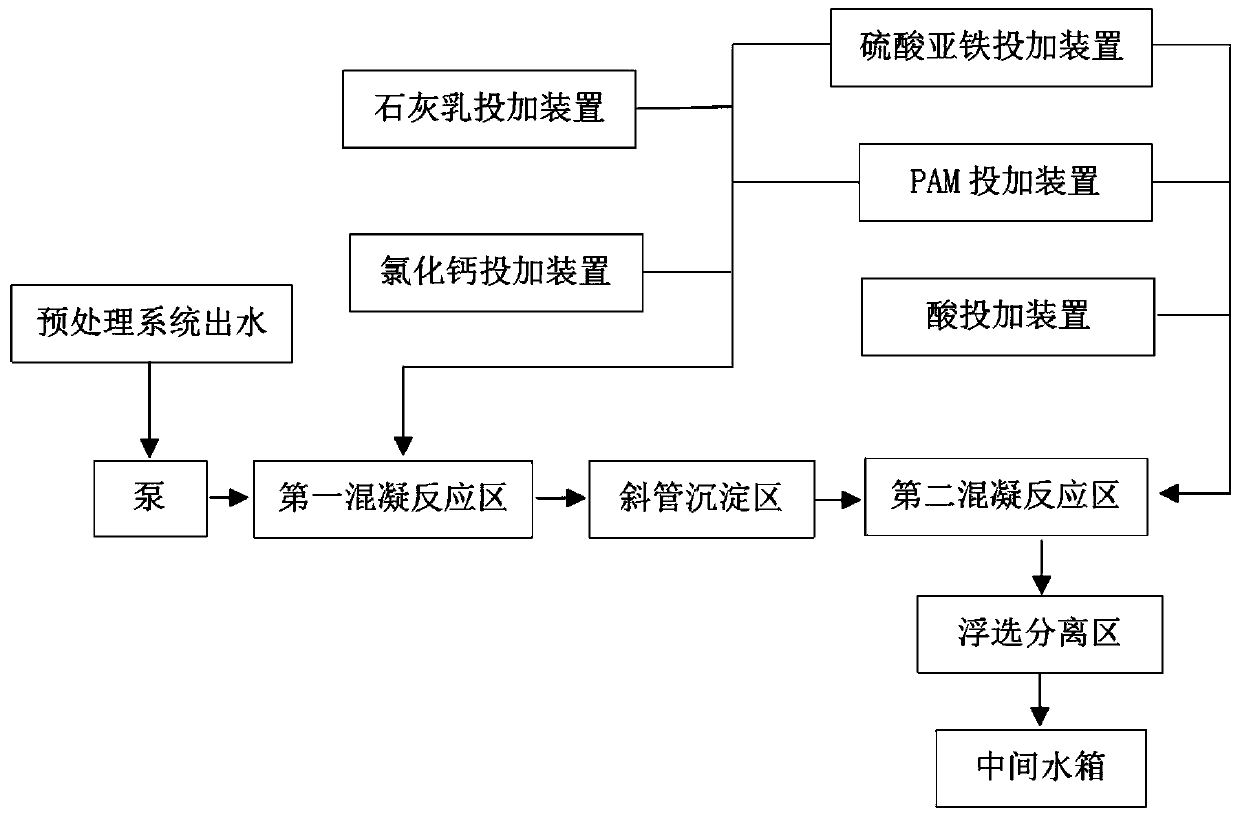

Method used

Image

Examples

Embodiment

[0043] For an air conditioner manufacturing company, the wastewater quality and discharge are as follows:

[0044]

[0045] The emission requirements are as follows:

[0046]

[0047]

[0048] The indicators of industrial water quality (GB / T 19923-2005) for urban sewage recycling are:

[0049] serial number monitoring project Emission standard (mg / L) 1 pH 6.5-9 (dimensionless) 2 COD / 3 BOD ≤10 4 SS ≤10 5 Petro / 6 anionic surfactant / 7 Ammonia nitrogen / 8 animal and vegetable oil /

[0050] Processing effect:

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com