Leather wastewater treatment system and method

A leather wastewater treatment system technology, applied in animal processing wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the large fluctuations in water quality and quantity of tannery wastewater, poor leather wastewater treatment effect, Sewage treatment environment is complex and other problems, to achieve the effect of simplifying the microbial denitrification process, reducing sludge production, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

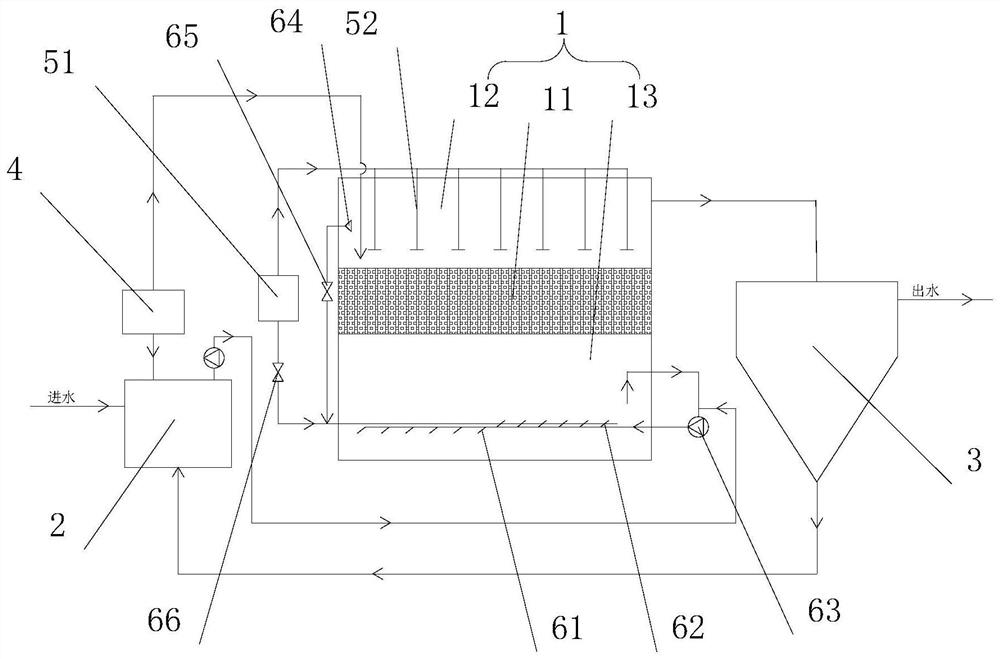

[0028] The leather waste water treatment system that present embodiment provides, specific technical scheme is as follows:

[0029] The leather wastewater treatment system includes a jet water distribution mixed digestion system, and a microbial agent containing heterotrophic nitrifying bacteria is placed in the jet flow water distribution mixed digestion system. The jet water distribution mixed digestion system includes a treatment tank 1, an intermediate pool 2 and a sedimentation tank 3. The middle part of the treatment tank 1 is provided with a biofilm 11. The biofilm 11 divides the treatment tank 1 into an aeration zone 12 and a jet mixing zone 13. The aeration Area 12 is provided with a water suction pipe 64 connected to the ejection pipeline of the second jet mixer 62 shown, and the nitrifying liquid in the digestion area is sucked into the jet mixer 62 and mixed into the jet mixing area 13, and the nitrification can be controlled by the backflow regulating valve 65 Liq...

Embodiment 2

[0042] In this example, the basal medium of the heterotrophic nitrifying bacteria Delftia tsuruhatensis HT01 is: MgSO4 7H2O 0.05g / L; K2HPO41g / L; NaCl 2g / L; FeSO4 7H2O 0.4g / L; NaHCO3 1.5g / L; ·2H2O 0.5g / L; trace elements 1mL / L; pure water.

[0043] Trace elements (1L): CuSO4·5H2O 0.075g; ZnSO4·7H2O 0.3g; CoCl2·6H2O 0.375g; MnCl2·2H2O 0.3g; EDTA 0.5g; NaMoO4·2H2O 0.22g; H3BO4 0.014g; pure water 1L.

[0044] Conventional carbon source medium: Add 0.4g / L NH4Cl as the only nitrogen source in the basal medium, and then add 2g / L sucrose, glucose, fructose, sodium citrate, sodium succinate, sugarcane molasses or sodium acetate as the only nitrogen source carbon source.

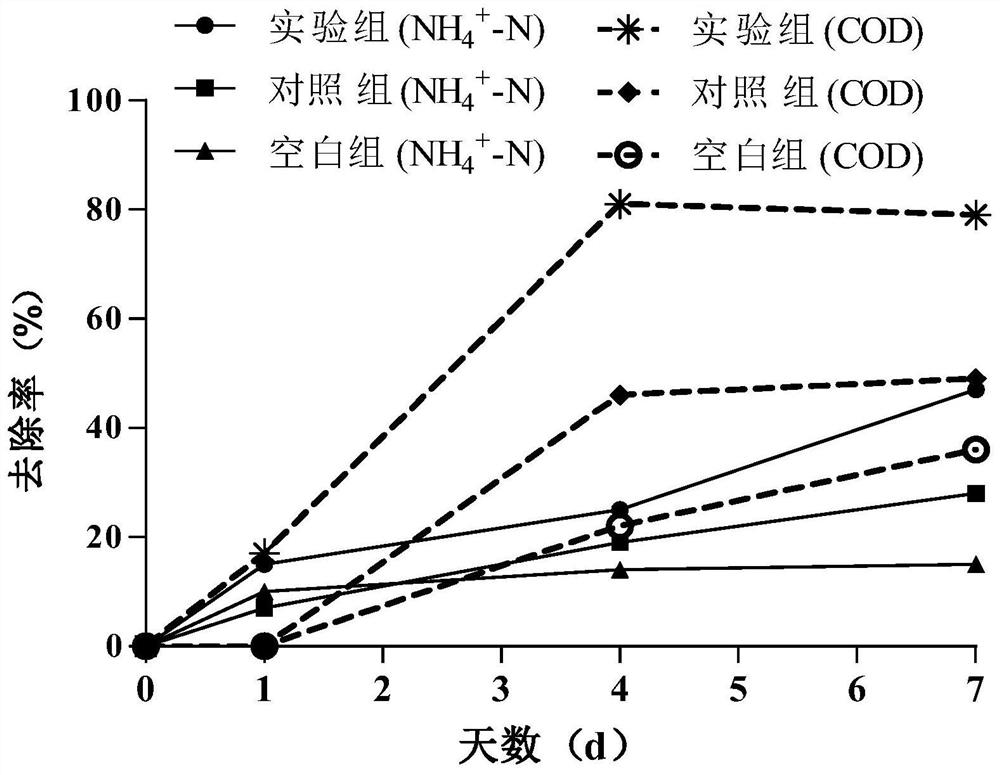

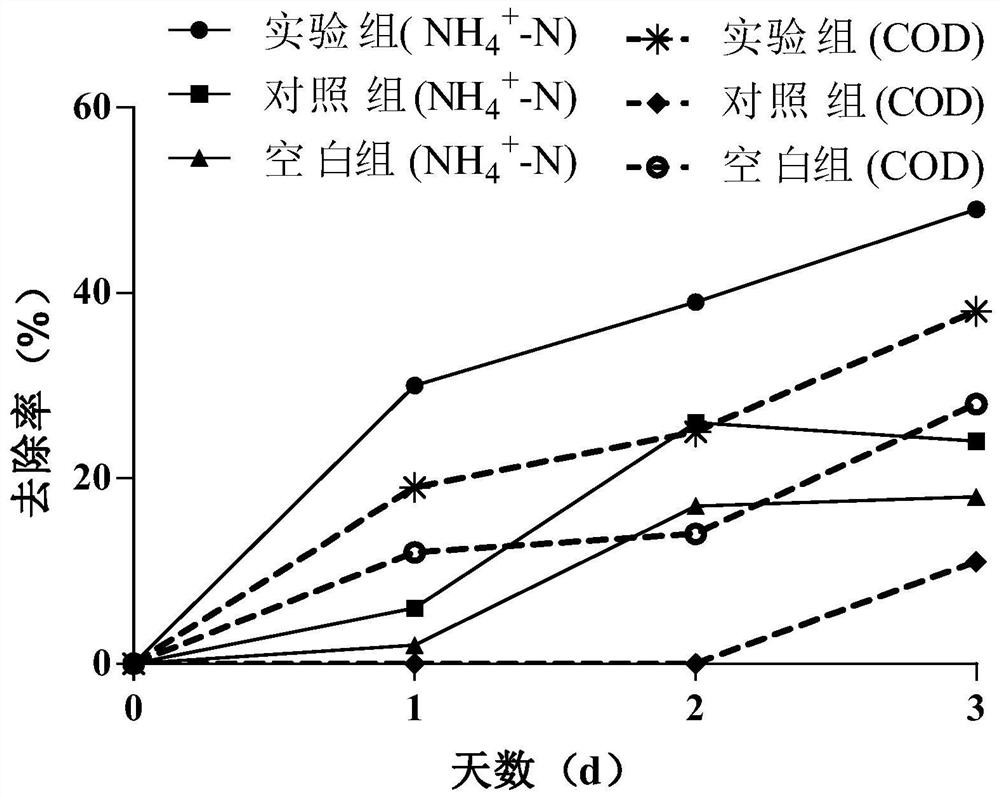

[0045] Taking leather sewage as the experimental material, the sewage is not suitable for the growth of autotrophic ammonia oxidizing bacteria due to its high salinity (about 20000mg / L). ~768mg / L. The experiment was carried out in two rounds. In the first round of the experiment, the experimental group inoculated 3....

Embodiment 3

[0051] The leather wastewater of a leather industry company in Xinji City used the leather wastewater treatment system and method provided in Example 1. The leather industry wastewater system can treat 1800m3 / d of wastewater per day. The amount of mud discharge is 60 tons (dry mud) / every day, the PAC consumption of the primary sedimentation tank is 200kg / d, and the PAM consumption is 8kg / d. After the leather waste water treatment system provided in Example 1 is put into use, the mud discharge amount is 40 tons (dry mud) / Every day, the PAC of the primary sedimentation tank is stopped, and the amount of PAM is 5kg / d. The pulse anaerobic tank can not only reduce the amount of sludge, but also reduce the amount of chemicals, and reduce operating costs for the enterprise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com