Cattle hair keratin modified oily polyurethane film preparation method

A technology of polyurethane film and polyurethane film, which is applied in the field of preparation of bovine hair keratin modified oily polyurethane film, can solve the problems of poor water vapor permeability and biodegradation of oily polyurethane, improve water vapor permeability, reduce the amount of reagents, improve The effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

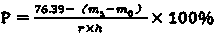

[0028] (1) Extraction of bovine hair keratin: keratin is extracted by a combination of ionic liquid-alkali method-oxidation. The washed and processed dry bovine hair was added to a three-necked flask, and nitrogen was introduced into it, and then 1-allyl-3-methylimidazolium chloride with 10 times the gross weight was added, and the reaction was heated and stirred for 1 hour at 90° C., And continue to use 400W ultrasonic treatment for 20 minutes at this temperature, then wash the cow hair twice with clean water, and dry it in an oven at 80°C for 6 hours. The dried cattle hair pretreated by the ionic liquid was first treated with 1.5mol / L NaOH solution for 30 minutes at a temperature of 90°C and a solid-to-liquid ratio of 1:20, and then added dropwise with a mass of 30% ( Gross weight) of hydrogen peroxide, continue to react for 1h, and the mechanical stirring rate is 180r / min. After the reaction, the hydrolyzate was cooled to room temperature for filtration, and then dialyzed ...

Embodiment 2

[0033] (1) Extraction of bovine hair keratin: keratin is extracted by a combination of ionic liquid-alkali method-oxidation. The washed and dried bovine hair was added to a three-necked flask, and nitrogen was introduced into the flask, and then 1-butyl-3-methylimidazole acetate with a gross weight of 15 times was added, and the reaction was heated and stirred for 1.5 hours at 70 ° C. Continue to use 350W ultrasonic treatment for 25 minutes at this temperature, then wash the cow hair with clean water 3 times, and dry it in an oven at 80°C for 6 hours. Under the condition of temperature of 85℃ and solid-to-liquid ratio of 1:20, the dried cow hair pretreated by ionic liquid was first treated with 1mol / L NaOH solution for 30 minutes, and then added dropwise with a mass of 20% (gross weight). ) of hydrogen peroxide, continue to react for 1h, and the mechanical stirring rate is 140r / min. After the reaction, the hydrolyzate was cooled to room temperature for filtration, and then di...

Embodiment 3

[0038] (1) Extraction of bovine hair keratin: keratin is extracted by a combination of ionic liquid-alkali method-oxidation. The washed and dried bovine hair was added to a three-necked flask, and nitrogen gas was introduced into it, and then 1-ethyl-3-methylimidazole acetate with a gross weight of 20 times was added, and the reaction was heated and stirred for 2 hours at 60 ° C. And continue to use 300W ultrasonic treatment for 30 minutes at this temperature, then wash the cow hair 3 times with clean water, and dry it in an oven at 80°C for 6 hours. The dried cattle hair after pretreatment with ionic liquid was treated with 0.8mol / L NaOH solution for 30 minutes at a temperature of 80 °C and a solid-to-liquid ratio of 1:20, and then added dropwise with a mass of 15% ( Gross weight) of hydrogen peroxide, continue to react for 1h, and the mechanical stirring rate is 200r / min. After the reaction, the hydrolyzate was cooled to room temperature for filtration, and then dialyzed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com