Coagulation method of ABS grafted latex for improving biodegradability of process sewage

An agglomeration method and biochemical technology, applied in the coagulation field of ABS grafted latex, can solve the problems of high efficiency/economy of the treatment process, rising cost per ton of sewage treatment, etc., to reduce the content of toxic cyano substances and improve biochemical properties the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Get 26kg of ABS grafted latex (317nm, solid content 40.8%), add 100g emulsion antioxidant (Zhejiang Shaofeng Plastic Industry SF-50LX), adopt IKA mechanical stirring to mix and set aside; 318g potassium hydrogen phthalate, Mix 159g of sulfuric acid and an appropriate amount of deionized water (adjust the amount of deionized water added according to the solid content of the target slurry), and prepare a mixed solution for use.

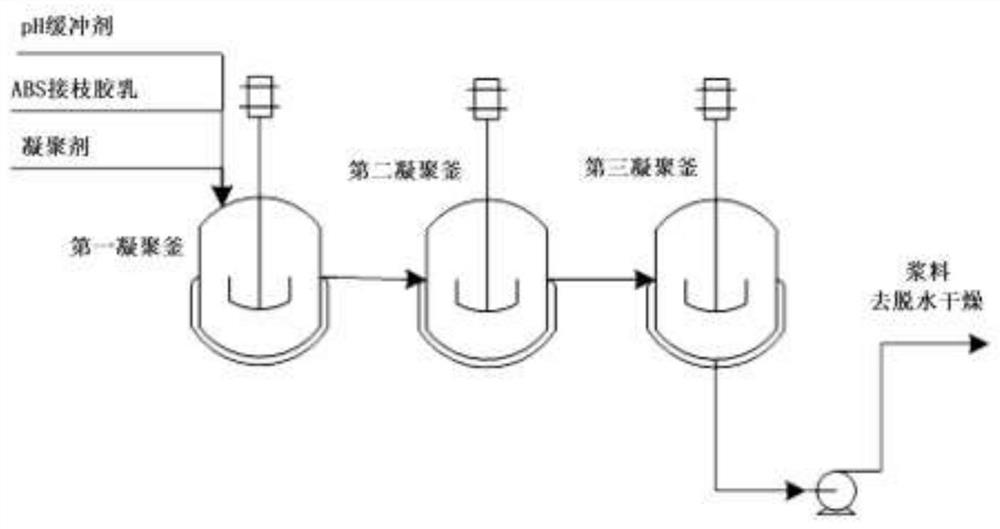

[0050] Nitrogen replacement of the three-tank continuous condensation reactor (see figure 1 process), open the first coagulation kettle, and continuously feed the previously configured mixed solution into the kettle. After the liquid level is established, control the internal temperature of the first coagulation kettle to 74°C, the second coagulation kettle to 90°C, and the second coagulation kettle to 90°C. The internal temperature of the three-condensation tank is 85°C, and the outlet pump flow rate is adjusted to control the residence time of ...

Embodiment 2

[0057] Get 26kg of ABS grafted latex (317nm, solid content 40.8%), add 100g emulsion antioxidant (Zhejiang Shaofeng Plastic Industry SF-50LX), adopt IKA mechanical stirring and mix for use; 106g aminoacetic acid, 74g phosphoric acid and appropriate amount Deionized water (adjust the amount of deionized water added according to the solid content of the target slurry) is mixed evenly and configured as a mixed solution for use.

[0058] Nitrogen replacement of the three-tank continuous condensation reactor (see figure 1 process), open the first coagulation tank, and continuously feed the previously configured mixed solution into the tank. After the liquid level is established, control the internal temperature of the first coagulation tank to 80°C, the second coagulation tank to 85°C, and the second coagulation tank to 85°C. The internal temperature of the three-condensation tank is 85°C, and the outlet pump flow rate is adjusted to control the residence time of each tank to be 1h...

Embodiment 3

[0064] Get 26kg of ABS graft latex (317nm, solid content 40.8%), add 100g emulsion antioxidant (Zhejiang Shaofeng Plastic Industry SF-50LX), adopt IKA mechanical stirring to mix and set aside; 53g hexamethylenetetramine, 318g of hydrochloric acid and an appropriate amount of deionized water (adjust the amount of deionized water added according to the solid content of the target slurry) were evenly mixed, and prepared into a mixed solution for use.

[0065] Nitrogen replacement of the three-tank continuous condensation reactor (see figure 1 process), open the first coagulation tank, and continuously feed the previously configured mixed solution into the tank. After the liquid level is established, control the internal temperature of the first coagulation tank to 65°C, the second coagulation tank to 90°C, and the second The internal temperature of the three-coagulation tank is 85°C, and at the same time, the flow rate of the outlet pump is adjusted to control the residence time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com