High-efficiency air-entrainer for roller compacted concrete and preparation method thereof

A technology of roller compacted concrete and air-entraining agent, applied in the preparation of high-efficiency air-entraining agent for roller-compacted concrete, and in the field of high-efficiency air-entraining agent for roller-compacted concrete, which can solve the problem of high air-entraining efficiency and foam stability of air-entraining agent Good, good solubility, etc., to achieve the effect of reduced production cost, good foam stability, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

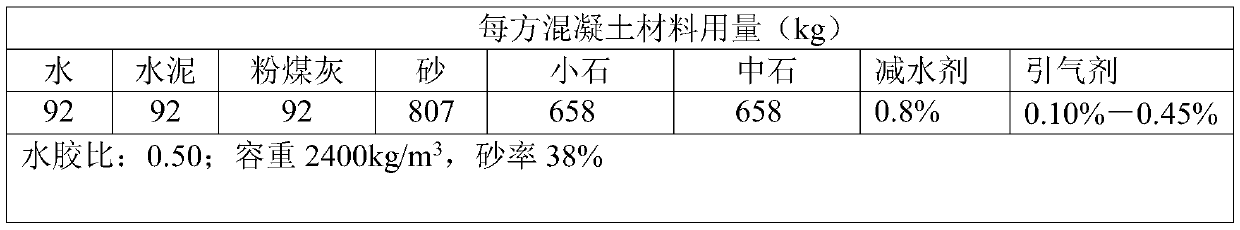

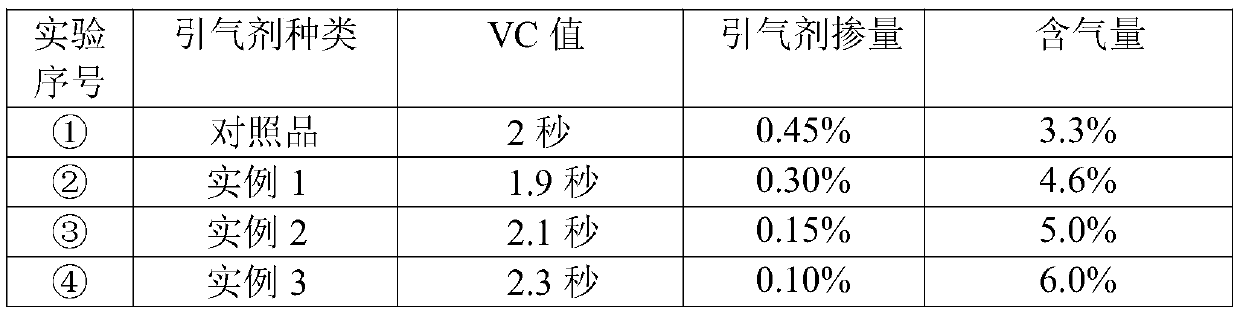

Method used

Image

Examples

Embodiment 1

[0016]Embodiment 1: The high-efficiency air-entraining agent for roller compacted concrete of the present invention is made of the following components and raw materials in parts by mass: 22 parts of 1,4-dibromobutane, long-chain alkyl primary amine That is, 43 parts of dodecyl primary amine, 16 parts of formaldehyde, 17 parts of formic acid, 38 parts of 3-chloro-2-hydroxypropanesulfonate sodium, 20 parts of deionized water, 100 parts of absolute ethanol, the mass percentage concentration is 28.5% The sodium hydroxide solution, its consumption should meet the requirement of the pH value of the solution after adjustment. The preparation method of the described high-efficiency air-entraining agent for roller compacted concrete comprises the following process steps: ① firstly add dodecyl primary amine and 30 parts of absolute ethanol into the there-necked bottle according to the mass parts of the above-mentioned raw materials, start the mechanical stirring, Heat the oil bath to 3...

Embodiment 2

[0017] Embodiment 2: The high-efficiency air-entraining agent for roller compacted concrete of the present invention is made of the following components and raw materials in parts by mass: 25 parts of 1,4-dibromobutane, long-chain alkyl primary amine That is, 50 parts of tetradecyl primary alkane, 18 parts of formaldehyde, 17 parts of formic acid, 42 parts of 3-chloro-2-hydroxypropanesulfonate sodium, 20 parts of deionized water, 105 parts of absolute ethanol, the mass percentage concentration is 30% Sodium hydroxide (water) solution, its consumption should meet the requirement of the pH value of solution after adjustment. The preparation method of the described high-efficiency air-entraining agent for roller compacted concrete comprises the following process steps: ① according to the mass fraction of the above-mentioned raw materials, first add tetradecyl primary alkane and 35 parts of absolute ethanol into the there-necked bottle, start the mechanical stirring, The temperatu...

Embodiment 3

[0018] Embodiment 3: The high-efficiency air-entraining agent for roller compacted concrete of the present invention is made of the following components and raw materials in parts by mass: 24 parts of 1,4-dibromobutane, hexadecyl primary amine 52 parts, 18 parts of formaldehyde, 16 parts of formic acid, 40 parts of sodium 3-chloro-2-hydroxypropanesulfonate, 30 parts of deionized water, 110 parts of absolute ethanol, and a sodium hydroxide solution with a mass percentage concentration of 28.5%. The dosage should meet the requirement of the pH value of the adjusted solution. The preparation method of the high-efficiency air-entraining agent for roller compacted concrete comprises the following process steps: 1. first add long-chain alkyl primary amines and 40 parts of absolute ethanol into the there-necked bottle according to the mass fraction of the above-mentioned raw materials, start mechanical stirring, Heat the oil bath to 35°C; ② Dissolve 1,4-dibromobutane in 25 parts of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com