High-voltage lithium ion battery electrolyte, additive and preparation method

An electrolyte additive and lithium-ion battery technology, applied in secondary batteries, chemical instruments and methods, secondary battery repair/maintenance, etc., can solve problems such as poor effect and high electrolyte cost, and achieve excellent safety performance and low cost Low, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

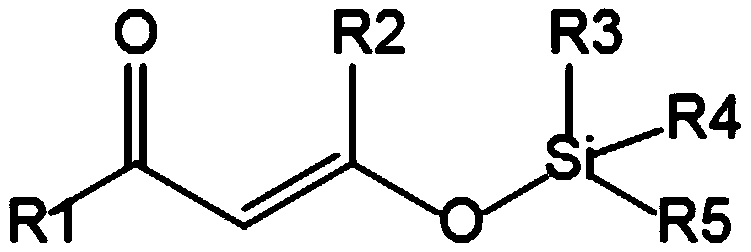

[0029] The structural formula of this additive 1 is as follows:

[0030]

[0031] Prepare the electrolyte using the following method:

[0032] (1.1) In a glove box filled with high-purity argon, fully mix fluoroethylene carbonate, methylethyl fluorocarbonate, and dimethyl fluorocarbonate in a mass ratio of 1:1:1 to obtain a mixture solvent;

[0033] (1.2) According to lithium salt LiPF 6 The concentration is 1mol / L, taking lithium salt into the mixed solvent and fully dispersing to obtain a dispersion solution;

[0034] (1.3) Add the additive with the above structural formula to the dispersion solution according to 0.5wt% by mass, and fully disperse to obtain the electrolyte solution D1 of this embodiment.

Embodiment 2

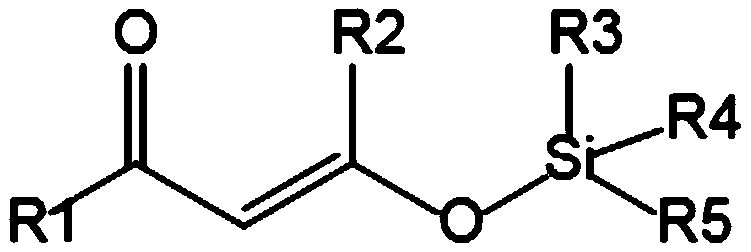

[0036] The structural formula of this additive 2 is as follows:

[0037]

[0038] Prepare the electrolyte using the following method:

[0039] (2.1) In a glove box filled with high-purity argon, fully mix chloropropylene carbonate, chlorodimethyl carbonate, and chlorodipropyl carbonate solvents according to a mass ratio of 1:0.5:1 to obtain a mixed solvent;

[0040] (2.2) According to lithium salt LiBF 4 The concentration is 0.8mol / L, taking lithium salt into the mixed solvent and fully dispersing to obtain a dispersion solution;

[0041] (2.3) Add the additive with the above structural formula to the dispersion solution according to 0.4wt% by weight, and fully disperse to obtain the electrolyte solution D2 of this embodiment.

Embodiment 3

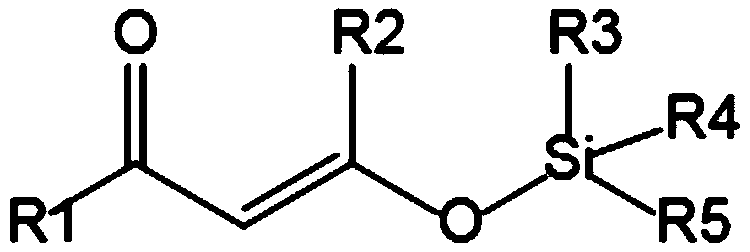

[0043] The structural formula of this additive 3 is as follows:

[0044]

[0045] Prepare the electrolyte using the following method:

[0046] (3.1) In a glove box filled with high-purity argon, fully mix bromobutylene carbonate, bromodiethyl carbonate, and bromomethyl ethyl carbonate solvents in a mass ratio of 1:2:1 to obtain a mixture solvent;

[0047] (3.2) According to lithium salt LiSO 3 CF 3 The concentration is 0.5mol / L, taking lithium salt into the mixed solvent and fully dispersing to obtain a dispersion solution;

[0048] (3.3) Add the additive with the above structural formula to the dispersion solution at 0.2wt% by mass, and fully disperse to obtain the electrolyte solution D3 of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com