Method for preparing water sound absorption polymer composite material

A composite material and polymer technology, applied in the field of ships, can solve the problems of poor adhesion and easy falling off, and achieve the effect of improving the sound absorption effect of underwater sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

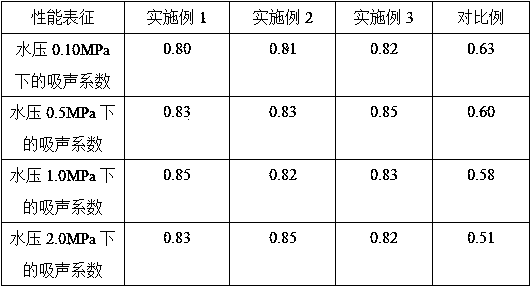

Examples

Embodiment Construction

[0043] In terms of parts by weight, weigh 20-30 parts of nano-zinc oxide powder, 100-150 parts of toluene, and 10-15 parts of vinyltriethoxysilane, add nano-zinc oxide powder into toluene, and heat at 50-60°C Under the condition of a water bath, stir and disperse at 600~700r / min for 30~40min, then place it in an ultrasonic disperser, and disperse ultrasonically for 20~30min under the condition of 400~500W to obtain a dispersion liquid. Vinyltriethoxysilane Slowly add to the dispersion at a rate of 20-30mL / min, stir and react at a speed of 200-240r / min in a water bath at 60-70°C for 10-12 hours to obtain a reaction solution, and place the reaction solution in a centrifuge , centrifuge at 3000~3500r / min at room temperature for 10~15min, remove the lower layer of solid, wash with absolute ethanol for 3~5 times, and then put it in a vacuum dryer at 60~80℃, 200~300Pa Vacuum dry for 1~2h to obtain modified nano-zinc oxide powder, and then weigh 100~120 parts of polypropylene glycol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com