Water-in-oil emulsion, preparation method thereof and oil-based drilling fluid

An oil-based drilling fluid, water-in-oil technology, applied in the field of drilling, can solve the problems of limiting drilling efficiency, lack of constant rheological properties in a wide temperature range, and high equivalent circulating density, and achieves excellent stability and excellent wide temperature range. Effects of constant rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

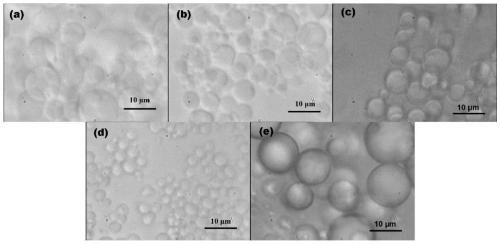

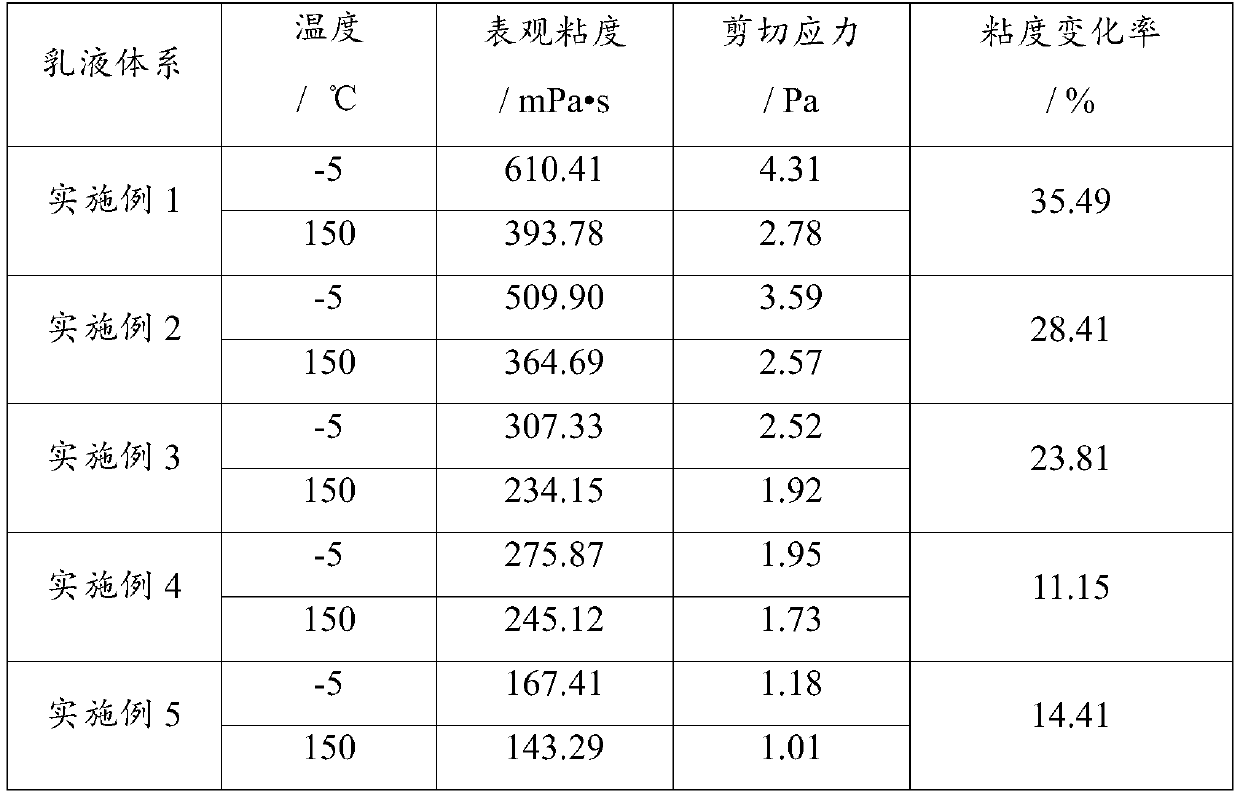

[0024] Weigh 0.5 parts by weight of methyl-modified fumed silica (the three-phase contact angle of the particles is 128°) and 60 parts by weight of gas-to-oil; add methyl-modified fumed silica particles to gas-to-oil, set the magnetic force The stirring speed is 600 rev / min, stirring for 10 minutes to disperse the methyl-modified fumed silica particles evenly in the gas-to-oil; weigh 39.5 parts by weight of calcium chloride aqueous solution with a concentration of 25wt%, and add it to the methyl-modified In the gas-phase silica particle-oil phase dispersion system, continue to magnetically stir at 600 rpm for 10 minutes and then sonicate, the ultrasonic power is 200W, and the ultrasonic time is 100s, and the water-in-oil emulsion is obtained.

Embodiment 2

[0026] Weigh 1 part by weight of ethyl-modified fumed silica (the three-phase contact angle of the particles is 143°) and 70 parts by weight of 3# white oil; add the ethyl-modified fumed silica particles to 3# white oil, set The rotating speed of constant magnetic stirring is 600 rev / min, and stirring for 10 minutes makes the ethyl modified fumed silicon oxide particles evenly dispersed in 3# white oil; Weigh 29.5 parts by weight of calcium chloride aqueous solution with a concentration of 15wt%, add it to In the ethyl-modified fumed silicon oxide particles-oil phase dispersion system, continue to magnetically stir at 600 rpm for 10 minutes and then ultrasonicate with an ultrasonic power of 200W and an ultrasonic time of 100s to obtain a water-in-oil emulsion.

Embodiment 3

[0028] Weigh 1.5 parts by weight of isopropyl modified fumed silica (the three-phase contact angle of the particles is 128°) and 80 parts by weight of 5# white oil; add the isopropyl modified fumed silica particles to 5# white oil , set the rotating speed of magnetic stirring to be 600 rpm, stir for 10 minutes to make the isopropyl modified fumed silicon oxide particles uniform in 5# white oil; take 19.5 parts by weight of calcium chloride aqueous solution with a concentration of 25wt%, and mix it Add isopropyl modified fumed silica particles-oil phase dispersion system, continue to magnetically stir at 600 rpm for 10 minutes, and then ultrasonicate with an ultrasonic power of 400W and an ultrasonic time of 50s to obtain a water-in-oil emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity change rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com