Improved fermentation tank

A fermenter and an improved technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the problem of insufficient two-phase contact, affecting product quality, and poor fermentation effect and other problems, to achieve the effect of improving the effect, increasing the dissolution rate of oxygen, and increasing the transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

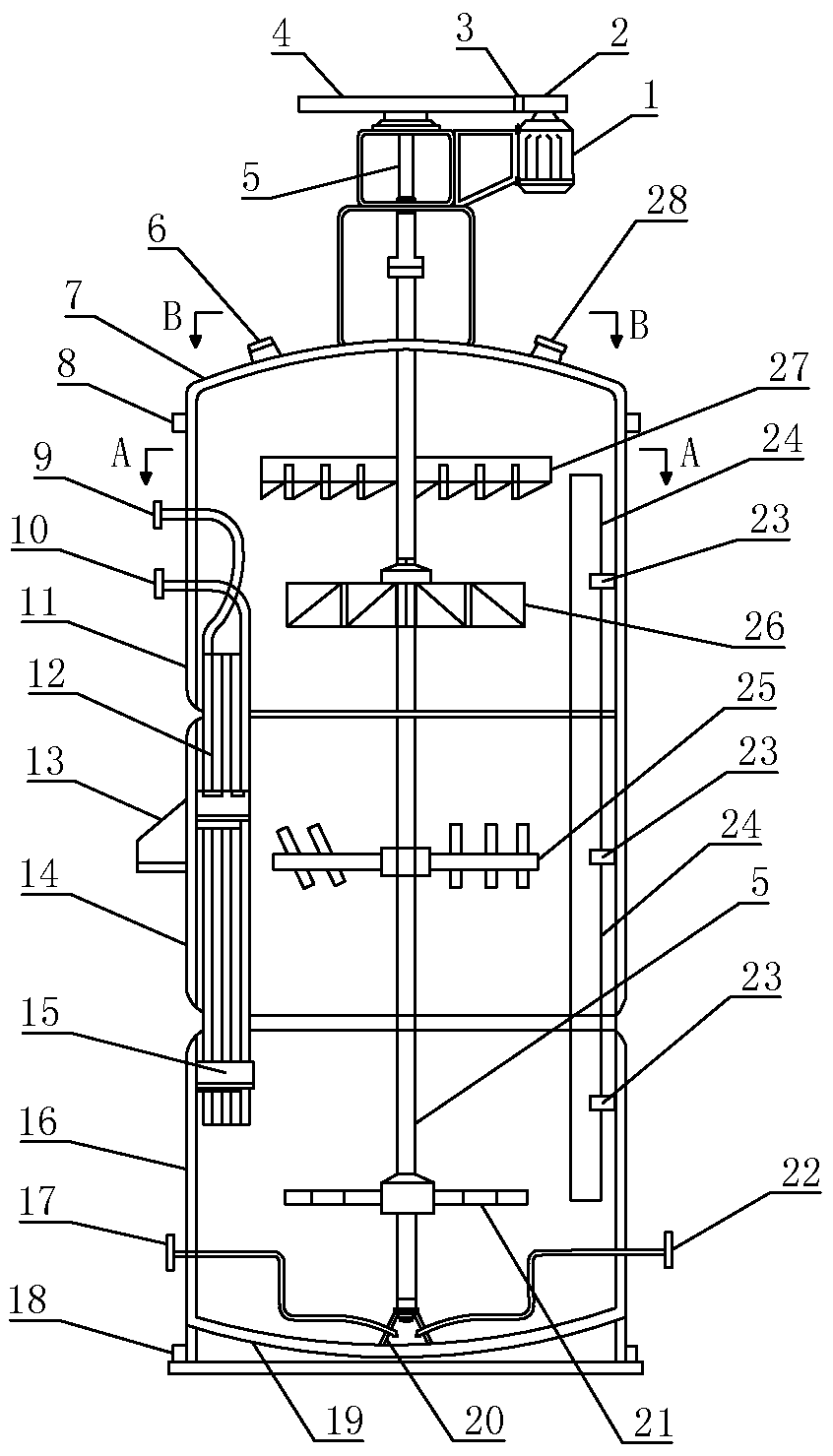

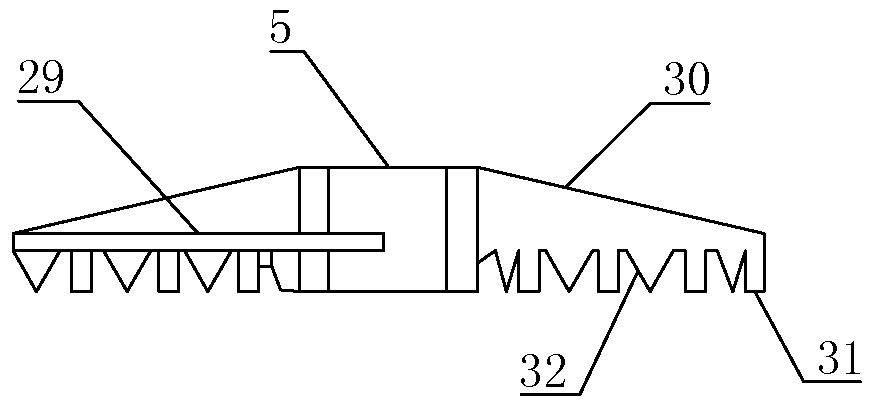

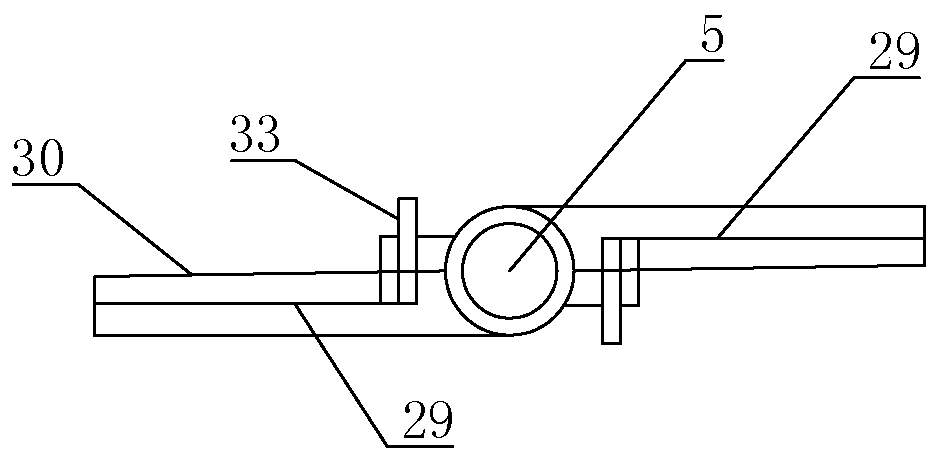

[0026] Such as Figure 1~9 As shown, the present invention provides a kind of improved fermenter, and it comprises main shaft 5 and upper head 7, barrel and lower head 19 that are connected in sequence, after one end of main shaft 5 passes through upper head 7, through transmission device and The motor 1 is connected, and the other end of the main shaft 5 passes through the cylinder and is fixed on the bottom of the lower head 19 through the bottom bearing 20, as Figure 9 As shown, the top of the upper head 7 is provided with a feed port 6 and an exhaust port 41, and the side wall of the lower part of the cylinder body is respectively provided with an air inlet 17 and a discharge port 22. Below the feed port 6, the cylinder body In the upper part of the cylinder, the main shaft 5 is equipped with a defoamer 27 and a fan-type agitator 26 in turn. In the middle of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com