Method for automatically grabbing blast furnace water slag through travelling crane

A blast furnace slag automatic technology, applied in the field of automatic grabbing of blast furnace slag by driving, can solve the problems of inability to judge the height of waste slag, damage the water filter device, affect efficiency, etc., and achieve manpower saving, high efficiency and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

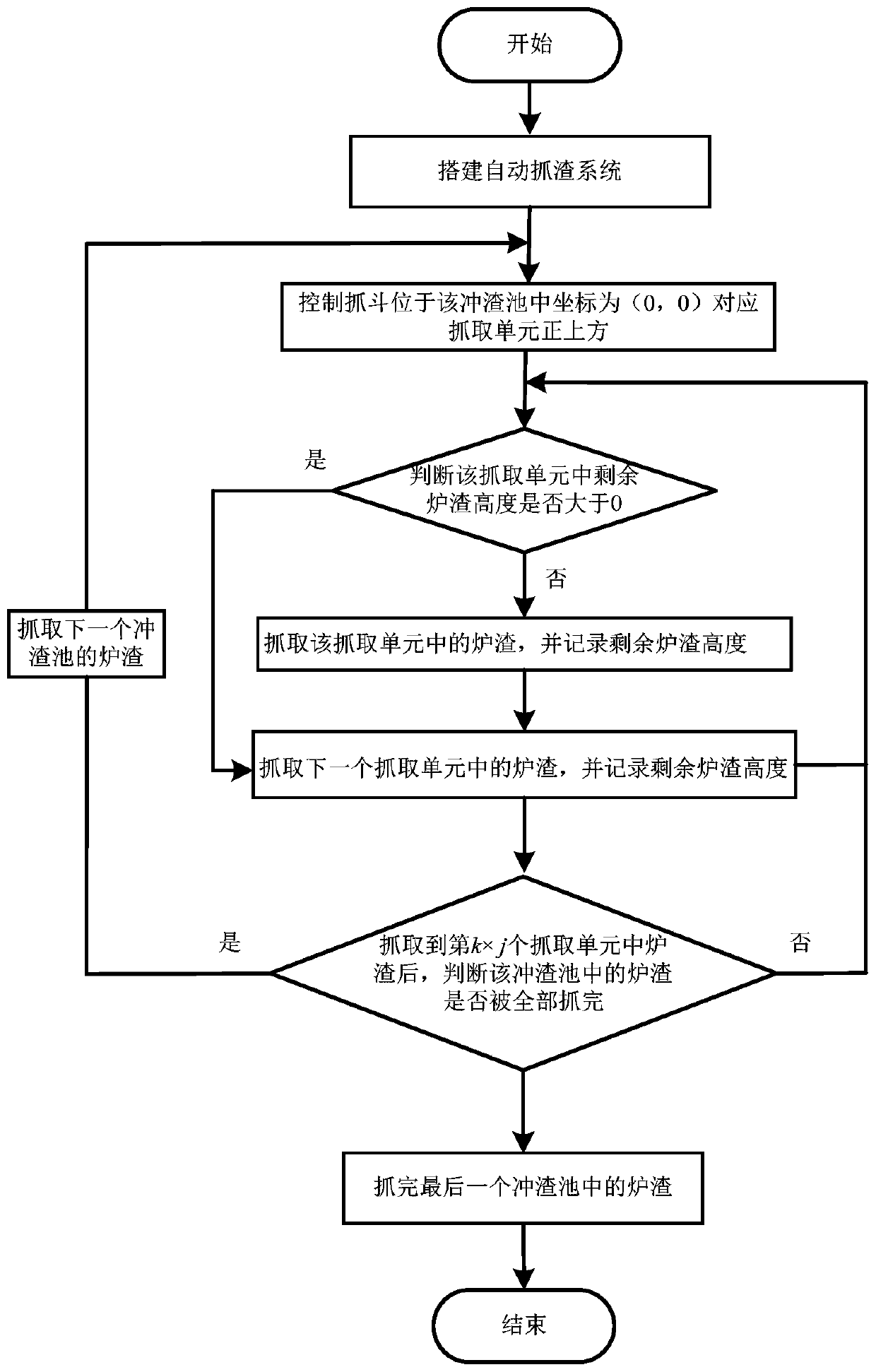

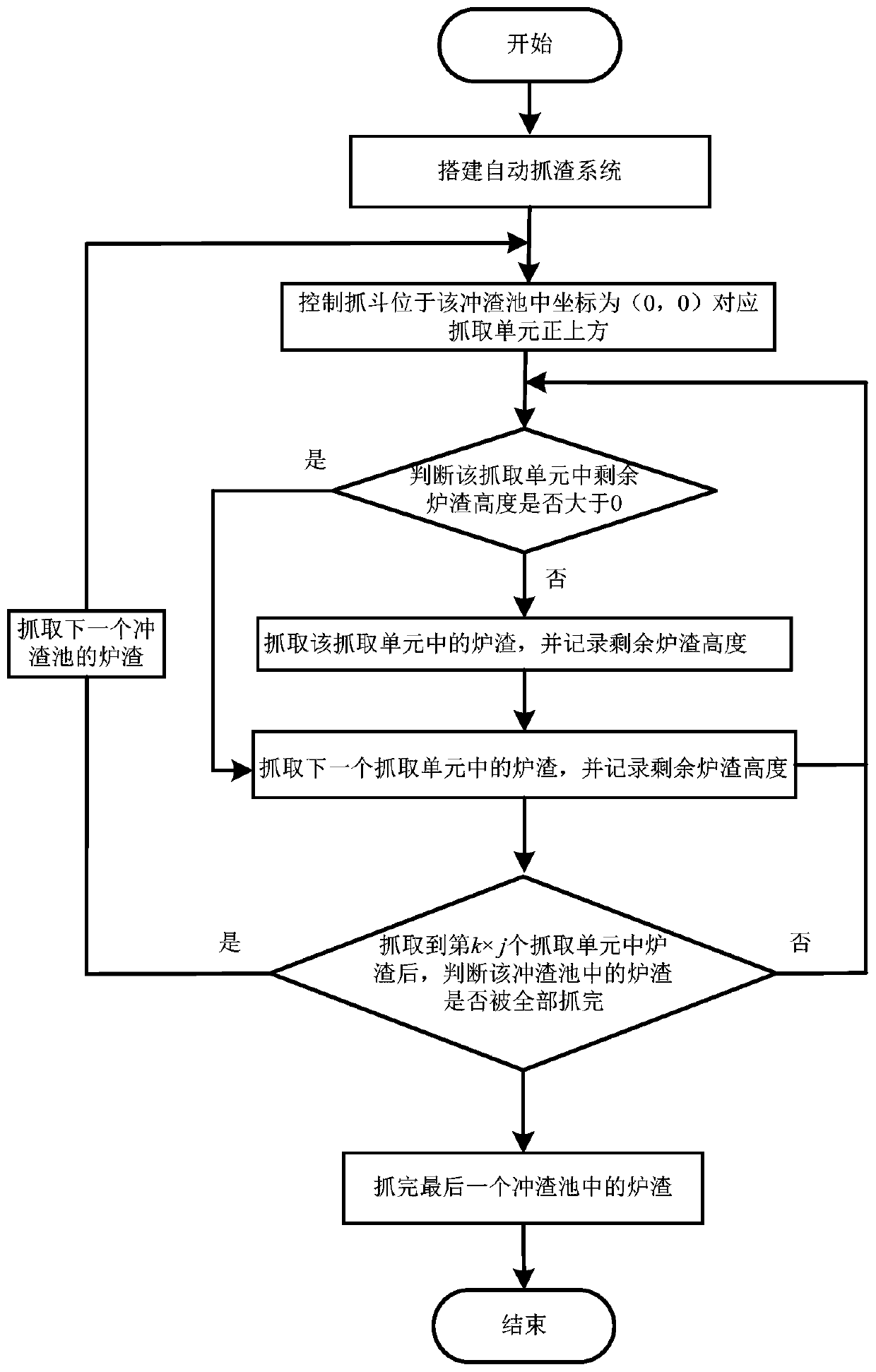

[0034] like figure 1 As shown, a method for automatically grasping blast furnace slag by driving a vehicle includes the following steps:

[0035] 1) Build an automatic slag grabbing system: including the controller, driving and grab bucket. The driving includes a cart and a trolley. There is a reel on the trolley. The trolley is driven by the first motor, the trolley is driven by the second motor, and the drum is driven by the second motor. Driven by three motors; a wire rope is wound on the reel, and a grab is connected to the lower end of the wire rope; a weight sensor is installed on the wire rope connected to the grab, and an absolute value encoder for detecting height is installed on the reel;

[0036] The first motor, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com