Covering yarn spun with flame retardant viscose and aramid blended coated cotton fiber and manufacturing technology thereof

A flame-retardant viscose and flame-retardant viscose fiber technology, which is applied in the field of textile production, can solve the problems of fire-resistant dripping, rough hand feeling of flame-retardant fabrics, low strength, etc. good combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

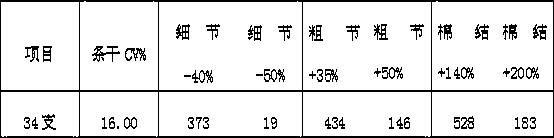

[0022] The present invention is a core-spun yarn spun from flame-retardant viscose and aramid fiber blended coated cotton filament, which is made of white flame-retardant viscose fiber 60%-70% and golden yellow aramid fiber F14 fiber 30%-40%. The spun roving is coated with nylon 66 20D filament in the spinning process to make yellow flame-retardant viscose and aramid F14 blended coated nylon 66 filament core-spun yarn; the flame-retardant yarn of the core-spun yarn is The viscose content accounts for 57% of the total weight of the blended yarn, the golden yellow aramid fiber F14 accounts for 30% of the total weight of the blended yarn, and the nylon 66 20D filament accounts for 13% of the total weight of the blended yarn. The thread count is 34. The flame-retardant viscose has a fineness of 4000 Nm, a length of 51mm, and a strength of 1.6CN / dtex; aramid 14 has a fineness of 6000 Nm, a main body length of 38mm, and a strength of 15.38CN / dtex.

[0023] A manufacturing process f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com