Substructure fabricated frame structure and construction method thereof

A frame structure and seed structure technology, which is applied in the field of sub-structure assembled and assembled structures and its construction, can solve the problem of difficulty in guaranteeing the construction quality at the joint between post-cast concrete and precast concrete due to the density of post-cast concrete, high difficulty in positioning and assembling operations, Unfavorable earthquake resistance and other issues, to improve the overall performance and seismic performance, reduce the number of connection nodes, and achieve the effect of dense joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to facilitate the understanding of the present invention, the following will describe the present invention more fully and in detail in combination with preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

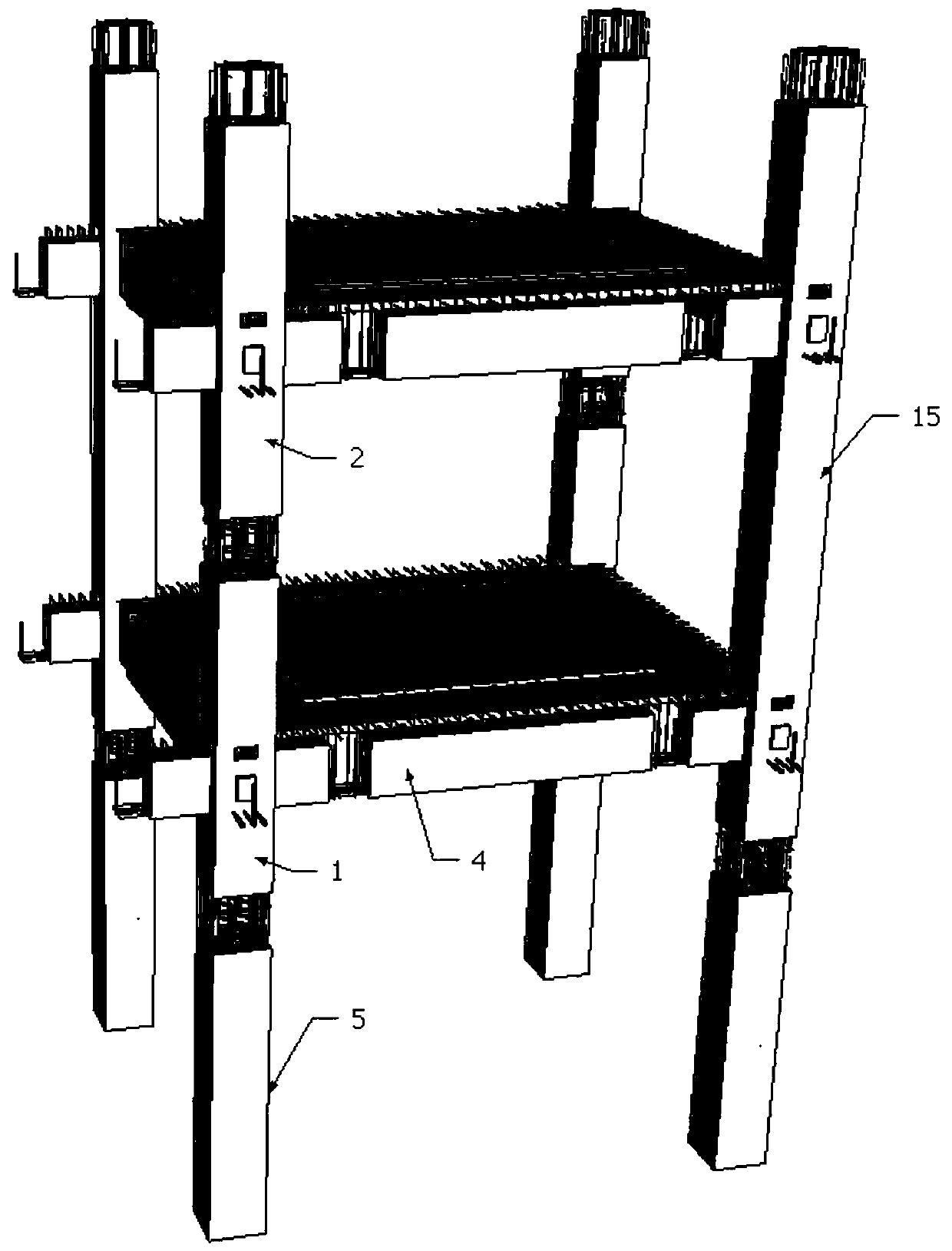

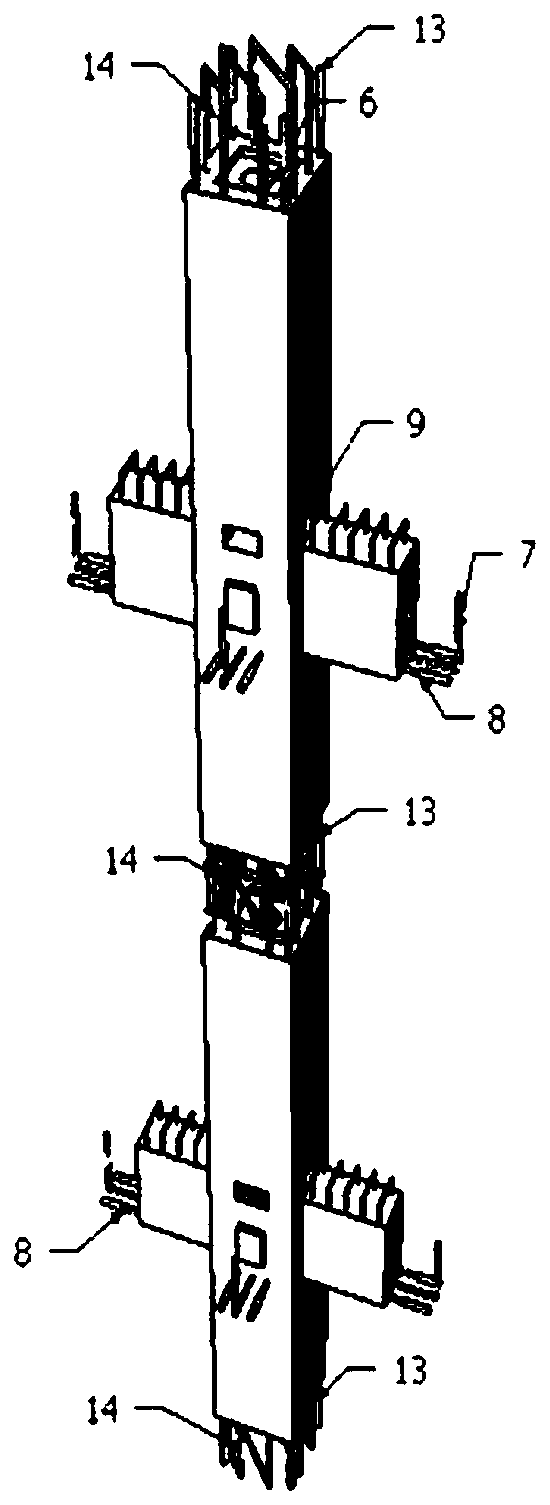

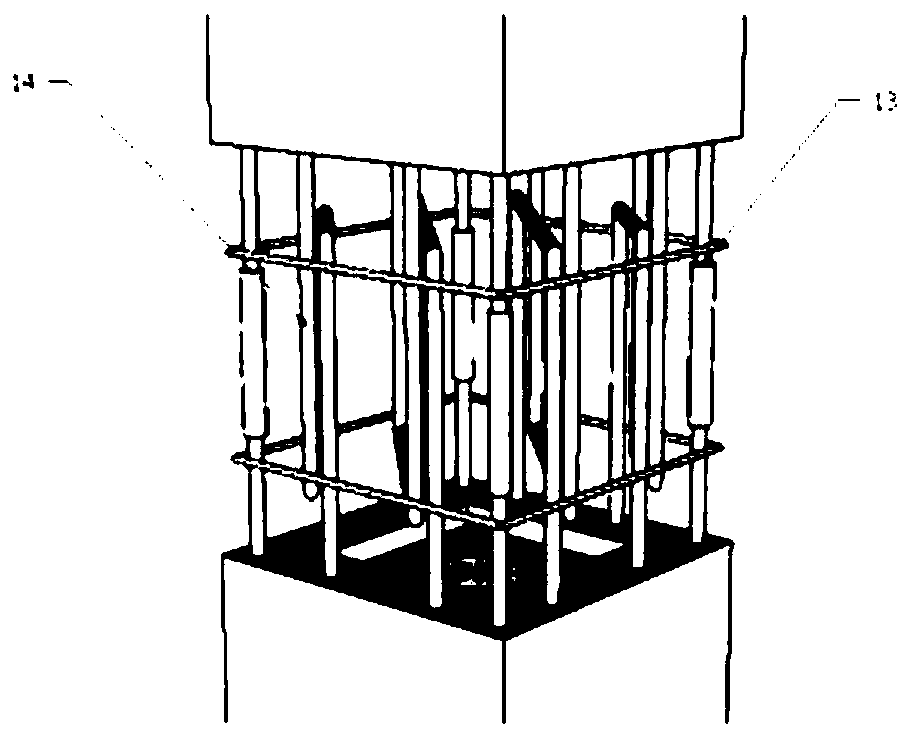

[0047] Such as Figure 1-9 As shown, a prefabricated sub-structure frame structure, including a plurality of prefabricated frame column structures, a plurality of prefabricated frame beam substructures and a plurality of prefabricated floor substructures; wherein the longitudinal force components are prefabricated frame column structures, and the horizontal force components For prefabricated frame column structure and prefabricated floor substructure.

[0048] The vertical splicing between the prefabricated frame column structures constitutes the columns of the frame structure, and the splicing nodes on the columns are longitudinal splicing nodes of the frame structure, and each vertic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap